Iterative learning optimization-based model prediction control method for loose damping machine

A technology of model predictive control and iterative learning, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as poor stability, reduce adjustment and operation, realize rapid movement, reduce labor intensity and Determining the effect of factors influencing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

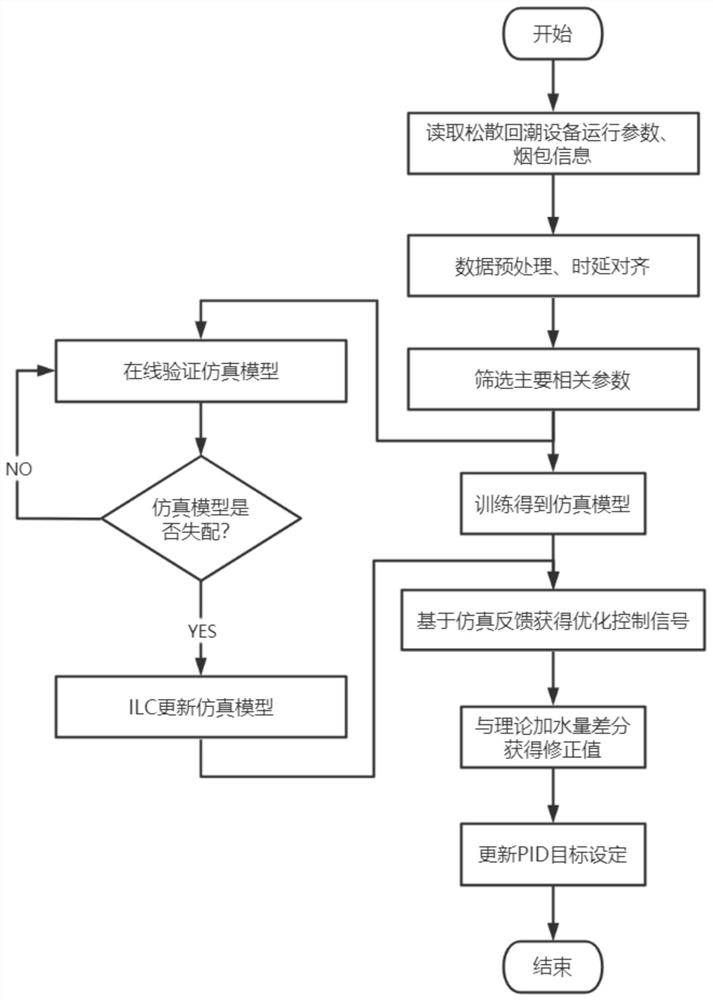

[0052] Please refer to figure 1 ,in, figure 1It is a structural schematic diagram of the first embodiment of a model predictive control method based on iterative learning optimization for a loose moisture regainer provided by the present invention. A model predictive control method based on iterative learning optimization for a loose moisture regainer, comprising the following steps:

[0053] S1: Standardize the original data and align it with delay;

[0054] S2: Select the main parameters that are highly correlated with the outlet moisture;

[0055] S3: Mechanism model and model parameters are obtained through regression calculation;

[0056] S4: Construct different types of tobacco leaf simulation models iterative learning cycle;

[0057] S5: Feedback control based on simulation model;

[0058] S6: The difference between the model prediction control signal and the theoretical water addition amount of the system is obtained, and the correction value of the water addition...

no. 2 example

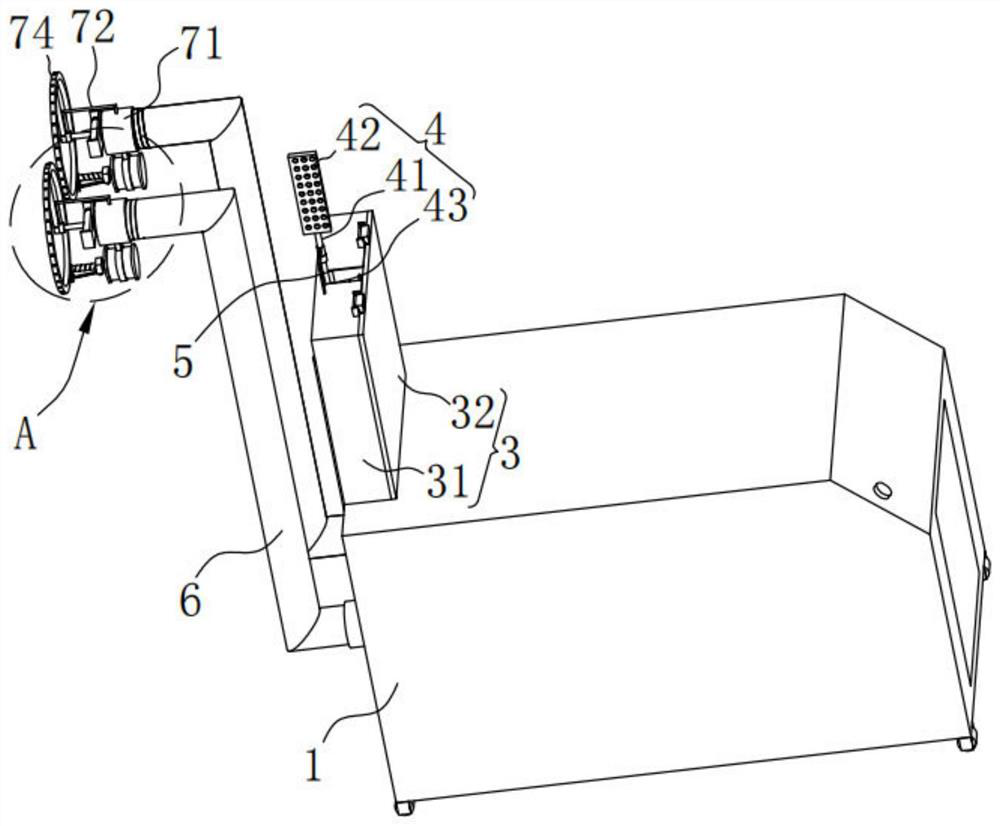

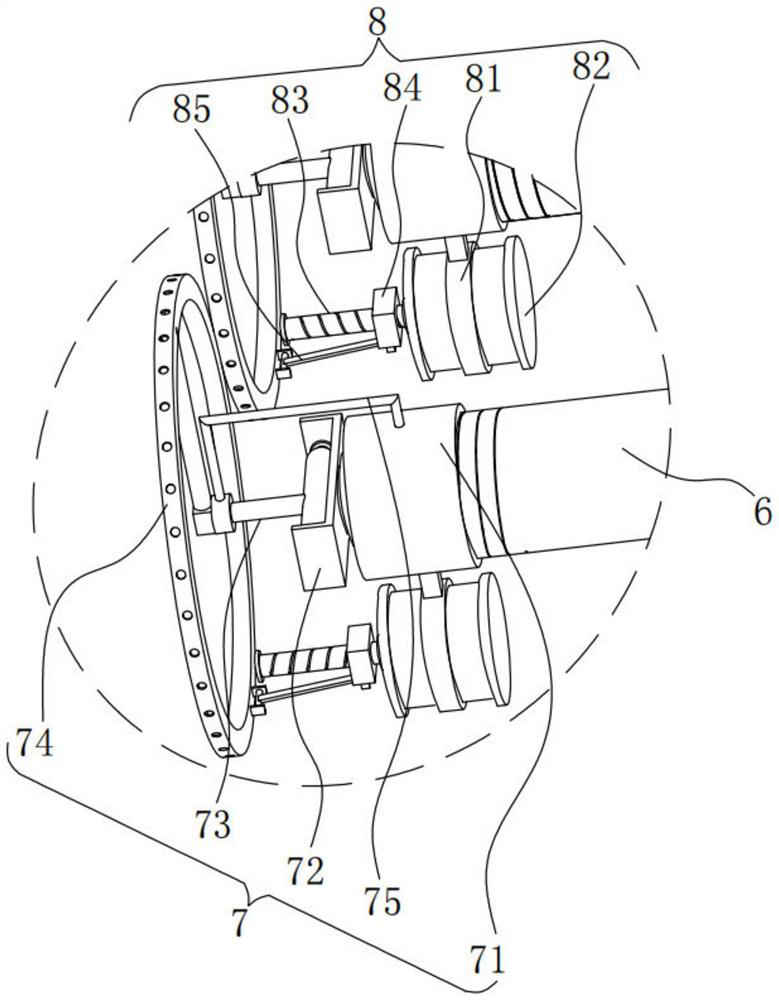

[0087] Please refer to figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , based on the model predictive control method based on iterative learning optimization for loose moisture regainers provided in the first embodiment of the present application, the second embodiment of the present application proposes another model predictive control method based on iterative learning optimization for loose moisture regainers. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0088] Specifically, the second embodiment of the present application provides a model predictive control method based on iterative learning optimization for a loose moisture regain machine. Loose dampening machine, comprising: device main body 1;

[0089] A smoke outlet pipe 6, the number of the smoke outlet pipes 6 is two, and the two smoke outlet pipes 6 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com