High-efficiency heat-dissipation variable-frequency speed-regulation three-phase asynchronous motor

A frequency conversion speed regulation, three-phase asynchronous technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of poor heat conduction and cooling effect, inconvenient heat conduction, rapid heating, etc., and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

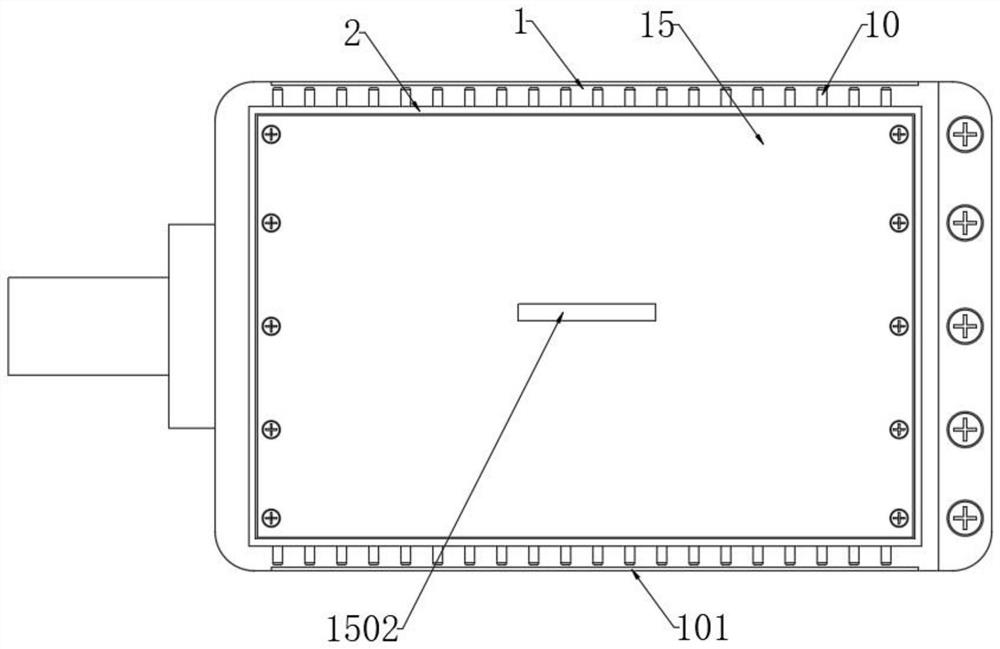

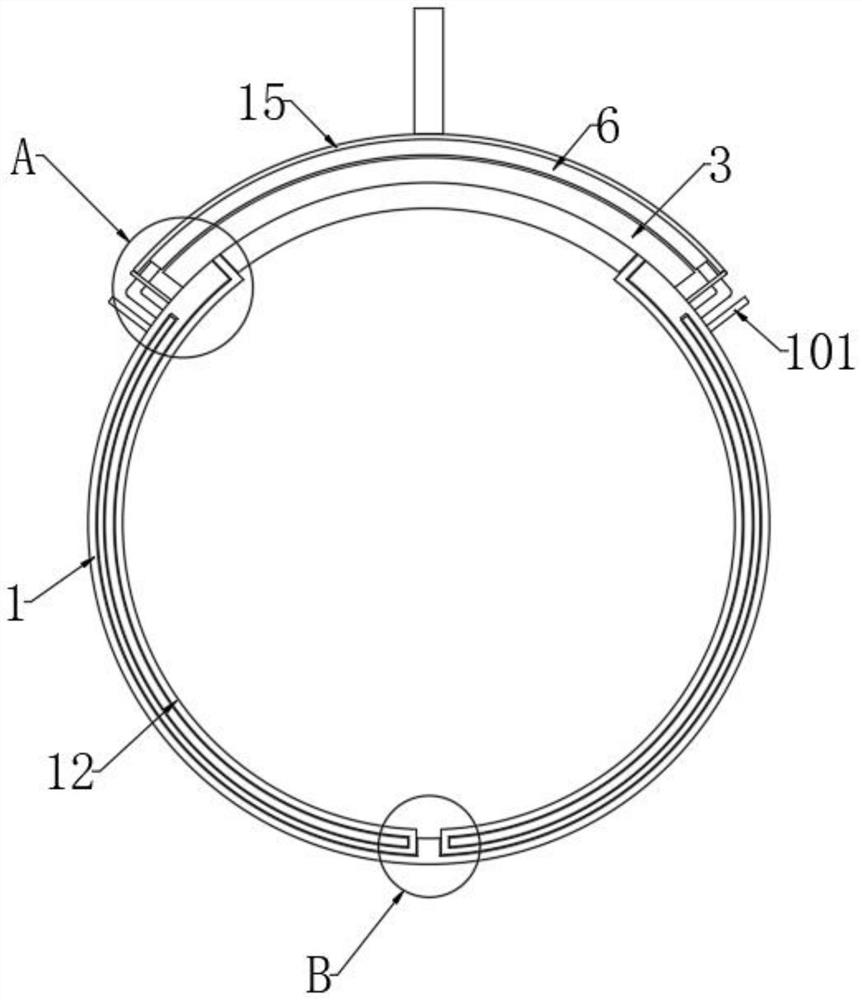

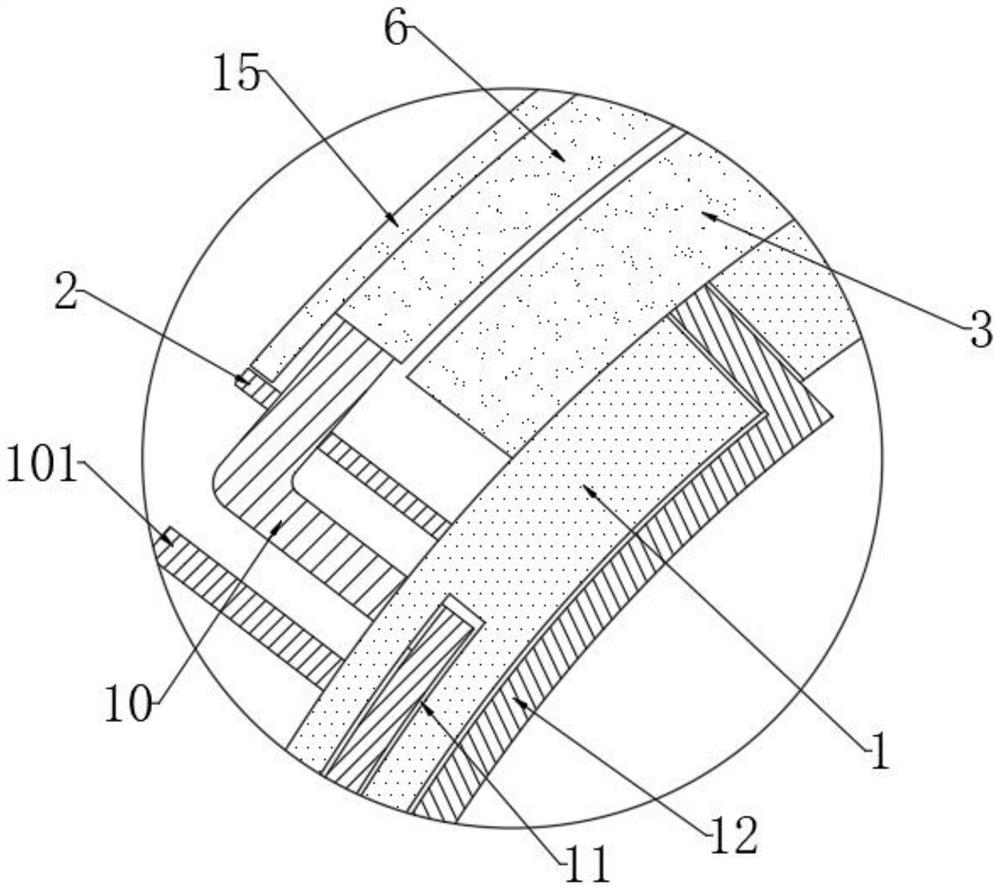

[0041] see Figure 1-7 , a high-efficiency heat dissipation frequency conversion speed regulation three-phase asynchronous motor, comprising a motor casing main body 1, the outer peripheral surface of the motor casing main body 1 is fixedly connected with a connecting arc frame 2, and the outer peripheral surface of the motor casing main body 1 is fixedly connected with a hollow cooling cycle arc Block 3, the inner cavity of the hollow cold circulation arc block 3 is fixedly connected with a carbon dioxide airbag 4, and the outer peripheral surface of the motor housing body 1 is dug with a heat conduction through hole 5, and the upper end of the hollow cold circulation arc block 3 is fixedly connected with a hollow refrigeration arc block 6 and the connecting pipe 7, the inner wall of the connecting pipe 7 is fixedly connected with a heat-expandable rubber block 8, and the upper end of the heat-expandable rubber block 8 is dug with a closed through hole 9, and both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com