Driving pump, cold plate assembly, mobile terminal device and electronic system

A technology for driving pumps and components, which is applied to pump components, mechanical equipment, components of pumping devices for elastic fluids, etc., and can solve problems such as poor heat dissipation performance of the heat dissipation system and inability to meet the heat dissipation needs of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

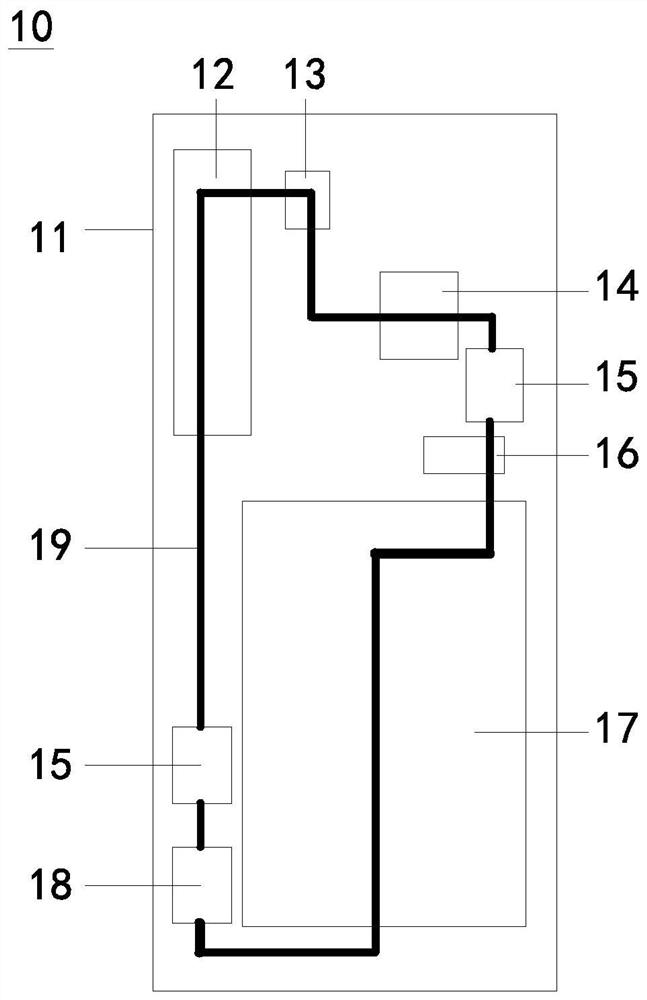

[0128] figure 1 It shows a structural frame diagram of the mobile terminal device 10 of the first embodiment. Such as figure 1 As shown, the mobile terminal device 10 may include a housing 11, and the housing 11 may be a single housing or a housing assembly assembled from several housings.

[0129] Such as figure 1 As shown, the mobile terminal device 10 may also include a heat generating device located in the casing 11 , a driving pump 18 , a liquid cooling control device 15 and a liquid cooling pipeline 19 . The liquid cooling pipeline 19 is connected to the driving pump 18 and the liquid cooling control device 15, and can pass through the heating element. There is flowable working medium in the liquid cooling pipeline 19 , the driving pump 18 and the liquid cooling control device 15 , and the liquid cooling pipeline 19 , the driving pump 18 and the liquid cooling control device 15 can constitute a flow pipeline of the working fluid.

[0130] The working medium can be co...

Embodiment approach 1

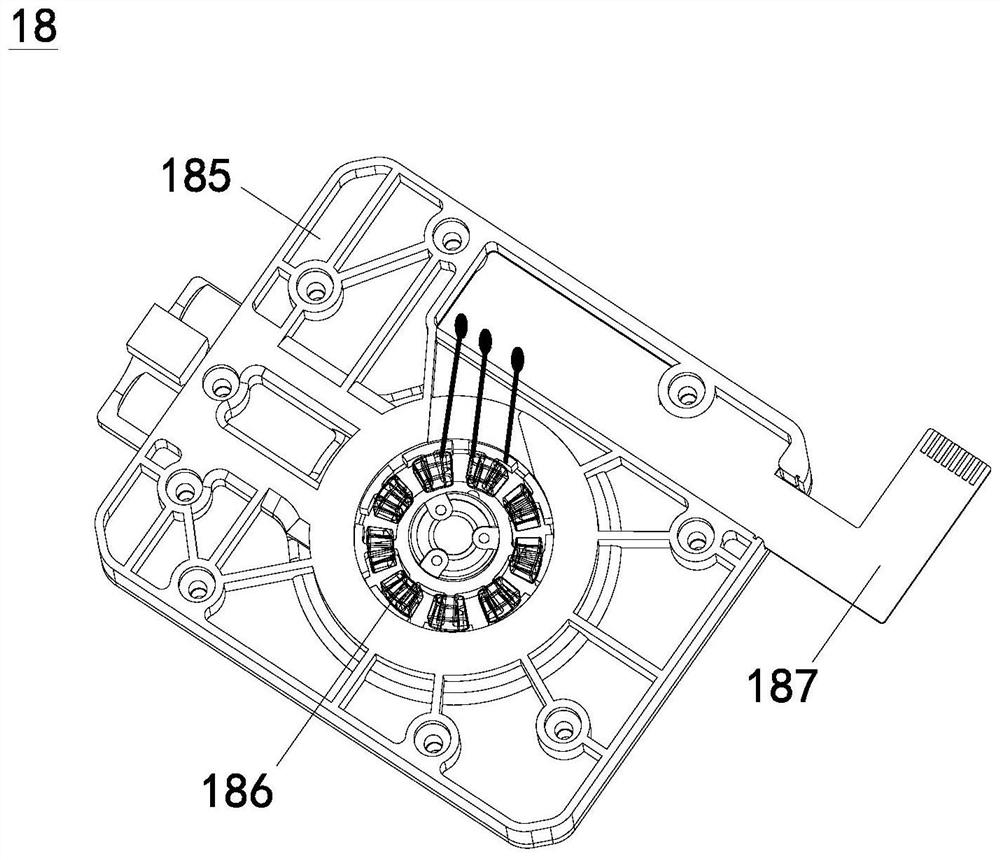

[0188] The scheme of Embodiment 1 can absorb impurities in the filter screen 152 by designing the liquid cooling control device 15, thereby blocking impurities in the liquid cooling control device 15, preventing them from entering the driving pump 18, and ensuring the working performance of the driving pump 18 , to avoid abnormalities such as stalling and noise in the drive pump 18.

[0189] Such as Figure 14 As shown, different from the liquid cooling control device 15 in the first embodiment, the liquid cooling control device 15 in the second embodiment may include at least two filters, such as the first filter 153, the second filter 154 and the third filter Net 155. The first filter 153 , the second filter 154 and the third filter 155 are arranged in sequence, the first filter 153 is close to the inlet 151 a, and the third filter 155 is close to the outlet 151 b. Each filter net can be connected, or can not be connected and keep a distance, for example, the first filter ...

Embodiment approach 2

[0191] The working principle of the liquid cooling control device 15 in the second embodiment is: when the working fluid carries impurities from the inlet 151a into the inner cavity of the housing 151, the impurities with larger particle sizes will be absorbed by the first filter screen 153, and the particles with larger particle sizes will be absorbed by the first filter screen 153. Medium ones will be adsorbed by the second filter screen 154 , and those with smaller particle diameters will be adsorbed by the third filter screen 155 . That is to say, the liquid cooling control device 15 has a hierarchical filtering function.

[0192] The scheme of Embodiment 2 can make the total fluid impedance of the liquid cooling control device 15 smaller by designing multi-stage filter nets, with better filtering effect, high reliability and longer replacement period.

[0193] Such as Figure 15 As shown, different from the above embodiments, the housing 151 of the liquid cooling control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com