Metal silicate catalyst regeneration

A metal silicate, catalyst technology, applied in catalyst regeneration/reactivation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problems of equipment required, expensive repetition, etc., to achieve excellent productivity, energy cost saving, excellent single The effect of alkyl ether selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

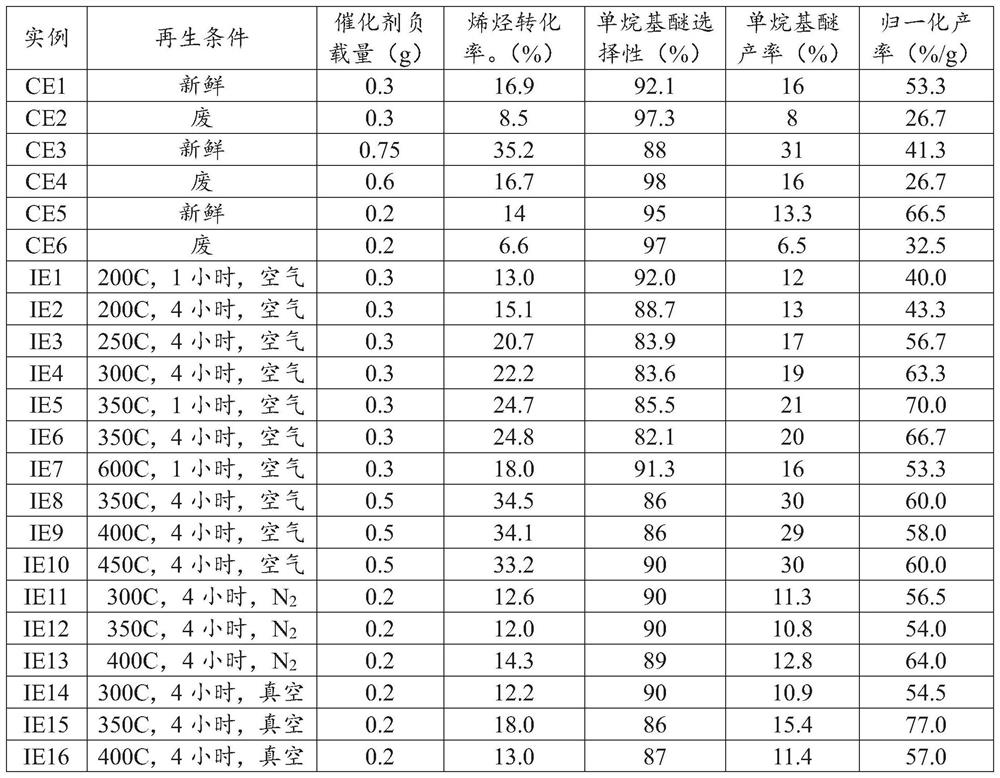

Examples

example

[0046] Material

[0047] The catalyst is a metallosilicate catalyst defined by the BEA structure and has a silica to alumina ratio of 25:1 and a 680m 2 surface area per gram, which is available as the CP814E from ZEOLYST INTERNATIONAL of Conshohocken, PA TM Commercially available.

[0048] The olefin is 1-dodecene alpha olefin which is available as NEODENE TM 12 Shell T from The Hague, Netherlands M Commercially available from the group.

[0049] Monoethylene glycol was purchased from Sigma Aldrich (SIGMAALDRICH) TM The liquid anhydrous ethylene glycol, its CAS number is 107-21-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com