Wave soldering automatic tin adding machine for PON/IPTV router PCB

A PCB board and wave soldering technology, applied in the direction of tin feeding device, printed circuit, welding equipment, etc., can solve the problems of increased labor cost, impact on productivity, personnel burns, etc., and achieve the goal of reducing labor cost, real-time intelligent detection and tin addition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

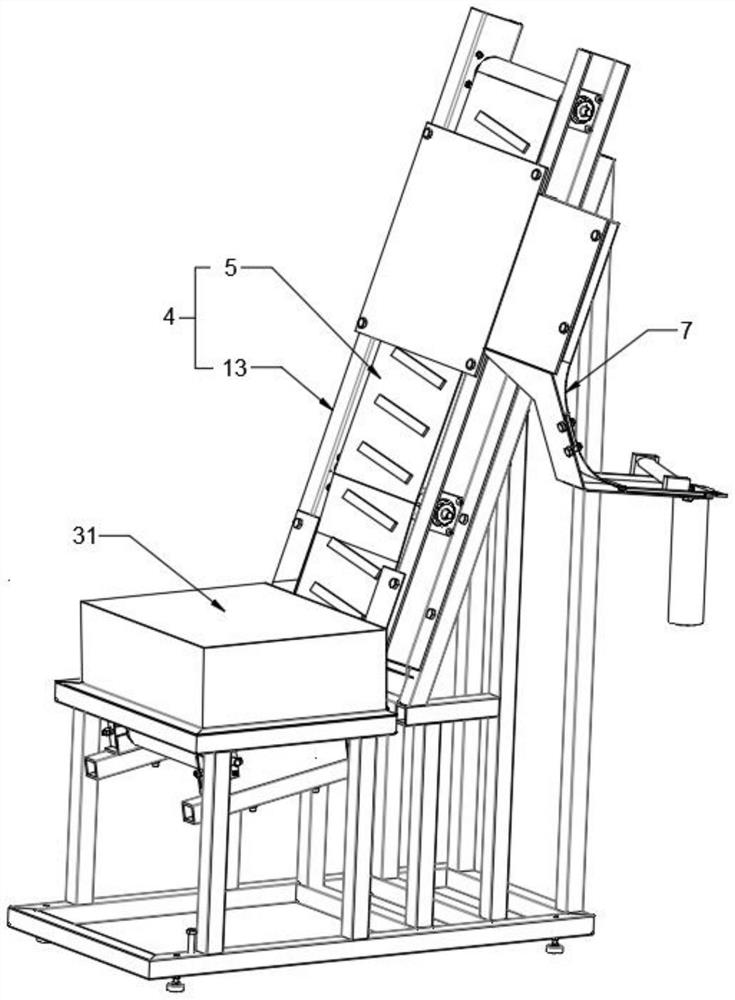

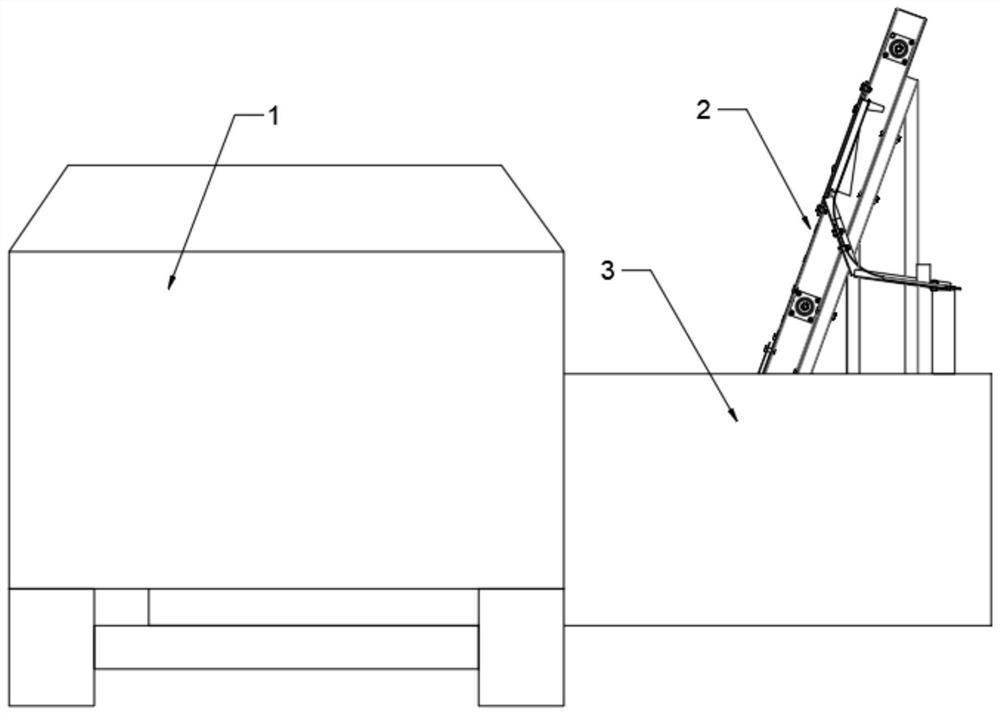

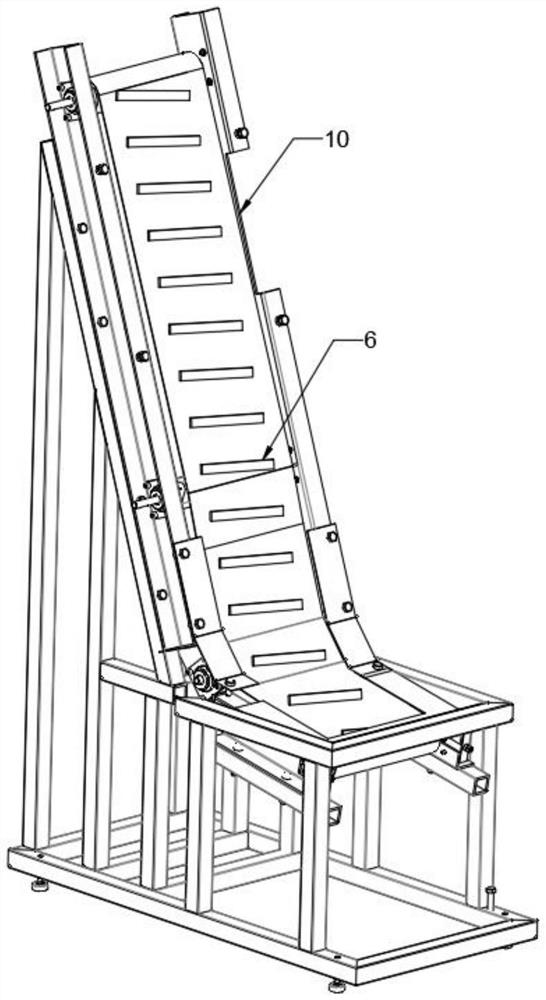

[0031] Embodiment one, as Figure 1 to Figure 4 As shown, a wave soldering automatic tinning machine for a PON / IPTV router PCB board includes a welding machine body 1 and an automatic tinning mechanism 2. A wave soldering tin tank 3 is provided under the welding machine body 1, and the automatic tinning mechanism 2 is used. To add tin bars to the wave soldering tin tank 3, the automatic tin adding mechanism 2 includes a conveyor belt 4, which is arranged obliquely, and is used to transfer the tin bars placed at a low place to a high place, that is, higher than the height of the wave soldering tin tank 3, and the conveyor belt 4 One side of the tin bar is provided with a tin bar guide conveying device 7, and the tin bar is turned and the conveying height of the tin bar is lowered by the tin bar guide transport device 7, so that the tin bar falls into the wave soldering tin tank 3 to realize the automatic tin adding process, and at the same time reduce the The added height of th...

Embodiment 2

[0034] Embodiment two, such as Figure 6 As shown, the top of the bar-shaped housing 16 is provided with a tin bar cutting mechanism 17, and the tin bar cutting mechanism 17 is located between the arc-shaped steering housing 15 and the hollow transmission cylinder 9, and the tin bar cutting mechanism 17 is used to cut the tin bar short The tin bar cutting mechanism 17 includes a cutter cylinder 18, a rotating shaft 19, a bar cam 20, a knife seat 21 and a blade 22, and the cutter cylinder 18 is fixedly installed on the top of the bar housing 16, and the cutter cylinder 18 can be installed on the bar through a bracket. On the shaped housing 16, a rotary shaft 19 is provided for rotation in the cutter cylinder 18, and one end of the rotary shaft 19 is connected with a motor, and the motor is installed on one end of the cutter cylinder 18, and the bar cam 20 is fixedly sleeved on the rotary shaft 19, and the knife seat 21 is arranged in the cutter barrel 18, the bottom of the cutt...

Embodiment 3

[0035] Embodiment three, such as Figure 7 As shown, the liquid level detection mechanism 12 includes a floating bar 26 and a floating ball 27. One end of the floating bar 26 is slidably connected with the inner wall of the wave soldering tin bath 3, and the floating bar 26 slides along the height direction of the tin liquid surface. The other end of the floating bar 26 One end is fixed with a floating ball 27, the floating ball 27 is provided with a probe 28, the wave soldering tank 3 is provided with a liquid level lower limit probe 29 and a liquid level upper limit probe 30, a liquid level lower limit probe 29 and a liquid level upper limit probe 30 are located on the moving path of the probe 28; the sliding direction of the floating ball 27 is controlled by the floating bar 26, so that the floating ball 27 drives the probe 28 to slide up and down. The tin mechanism starts to automatically add tin. When the probe 28 contacts the liquid level upper limit probe 30, the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com