Automatic welding mechanism for clothes rack panel

An automatic welding and clothing rack technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low processing efficiency, achieve the effect of improving welding efficiency and reducing blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

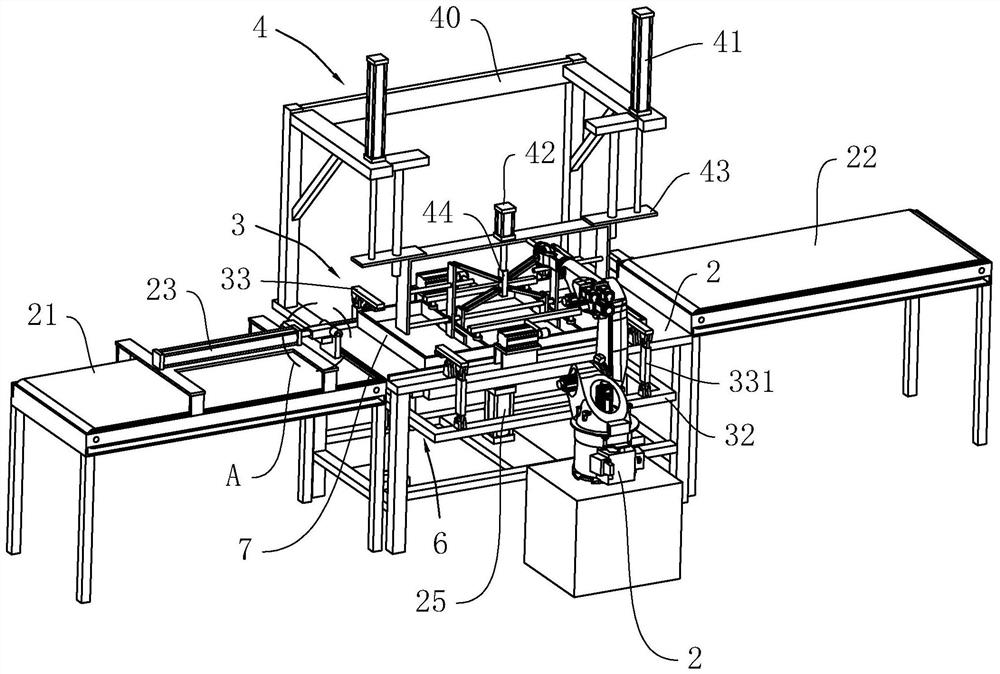

[0037] The following is attached Figure 2-7 The application is described in further detail.

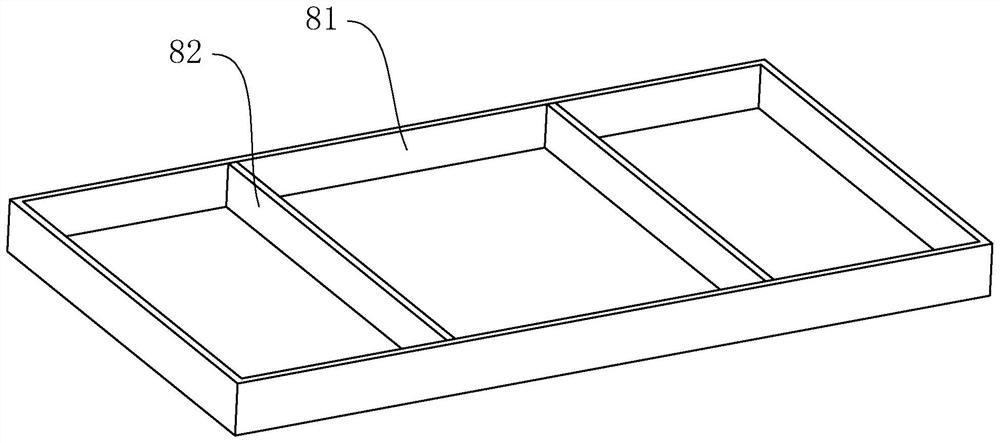

[0038] The embodiment of the present application discloses an automatic welding mechanism for a garment rack panel.

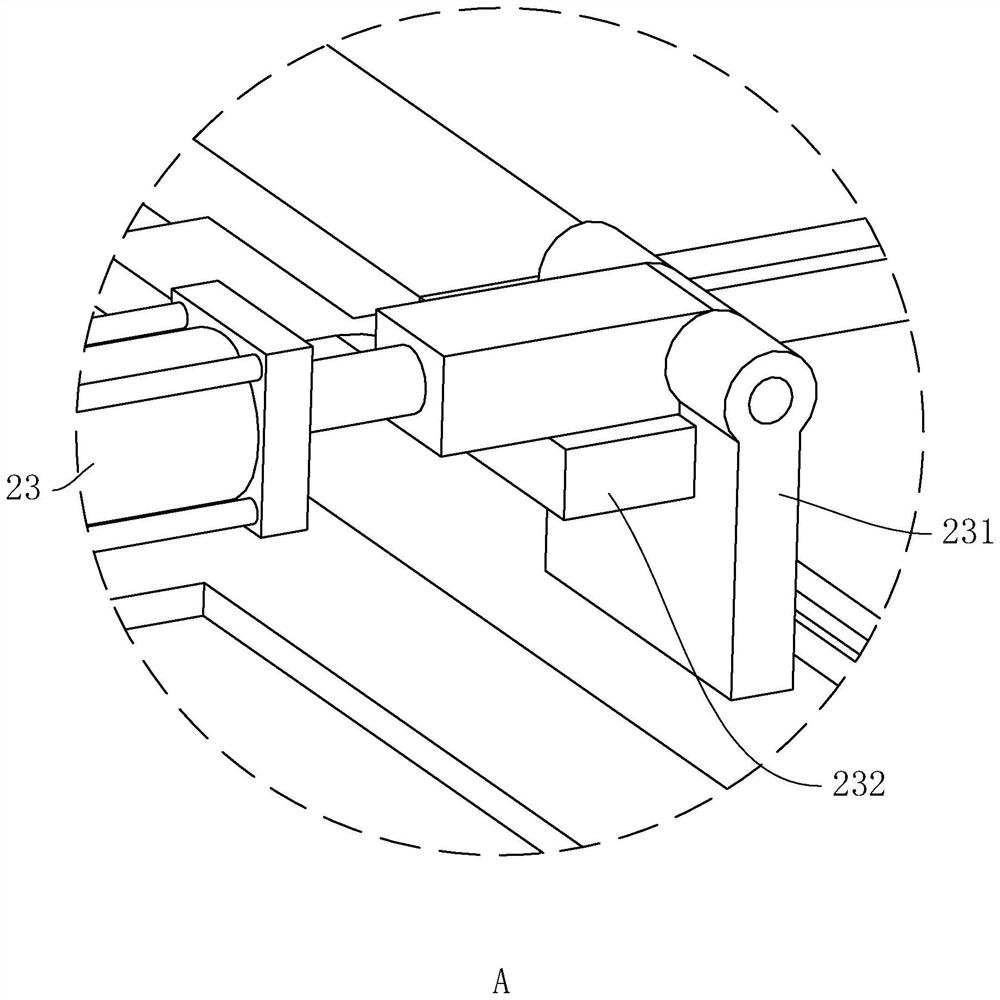

[0039] Such as figure 2 and image 3 , the automatic welding mechanism of the garment rack panel includes a welding robot 1 and a frame 2, the two sides of the frame 2 are respectively provided with a first conveyor 21 and a second conveyor 22, and the first conveyor 21 and the second conveyor 22 Transmission direction is identical and both adopt belt 651 machine, the belt 651 upper end surface of the first conveyor 21 is flush with frame 2, the belt 651 upper end surface of the second conveyor 22 is higher than frame 2, the first conveyor 21 An electric push rod 23 parallel to it is installed near one end of the frame 2, the drive end of the electric push rod 23 faces the frame 2 and is hinged with a push plate 231, and the bottom surface of the drive end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com