Parallel side beam structure for electric vehicle

A technology for electric vehicles and side beams, which is applied in the directions of motor vehicles, substructures, superstructures, etc., can solve the problems of damage and large deformation of the sidebars, and achieve the effects of reducing weight, improving performance and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

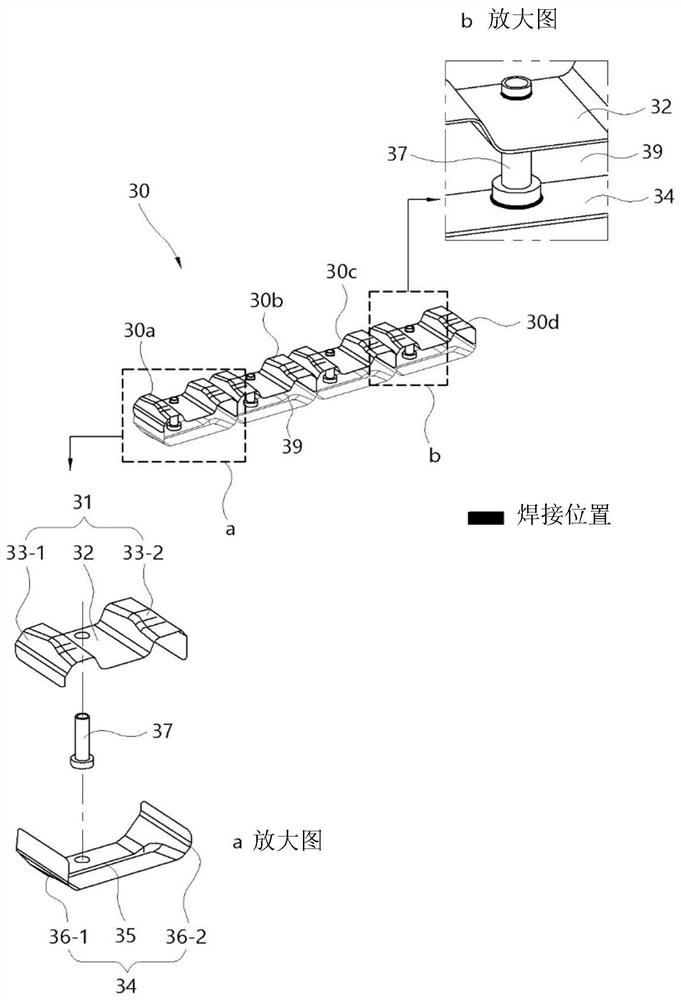

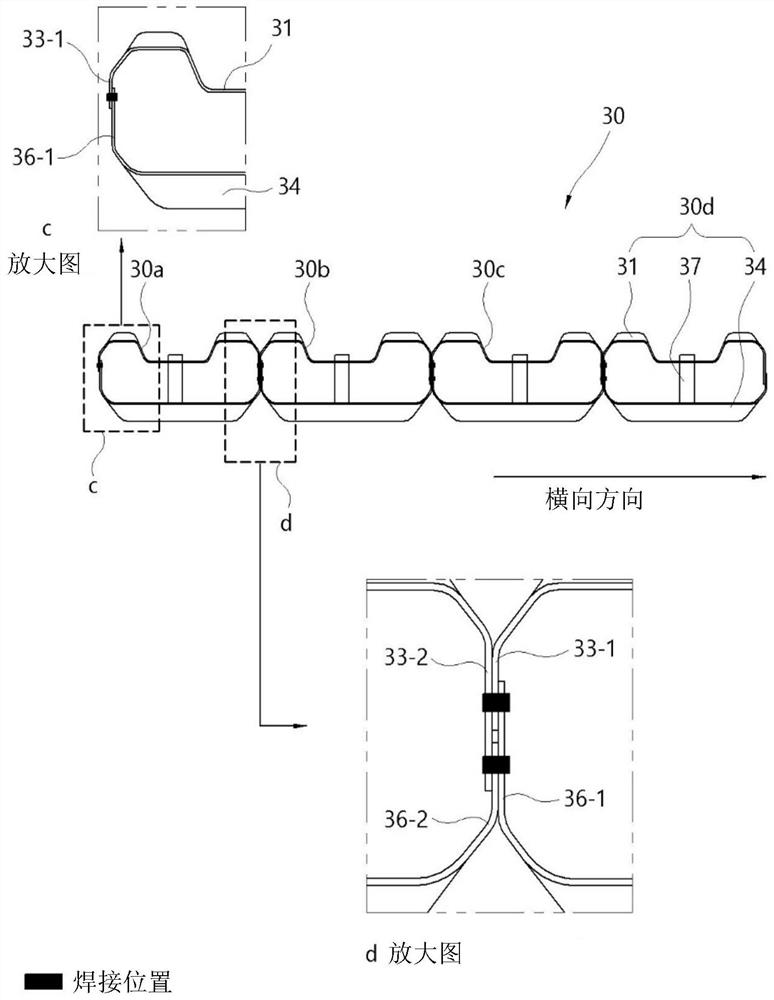

[0038] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

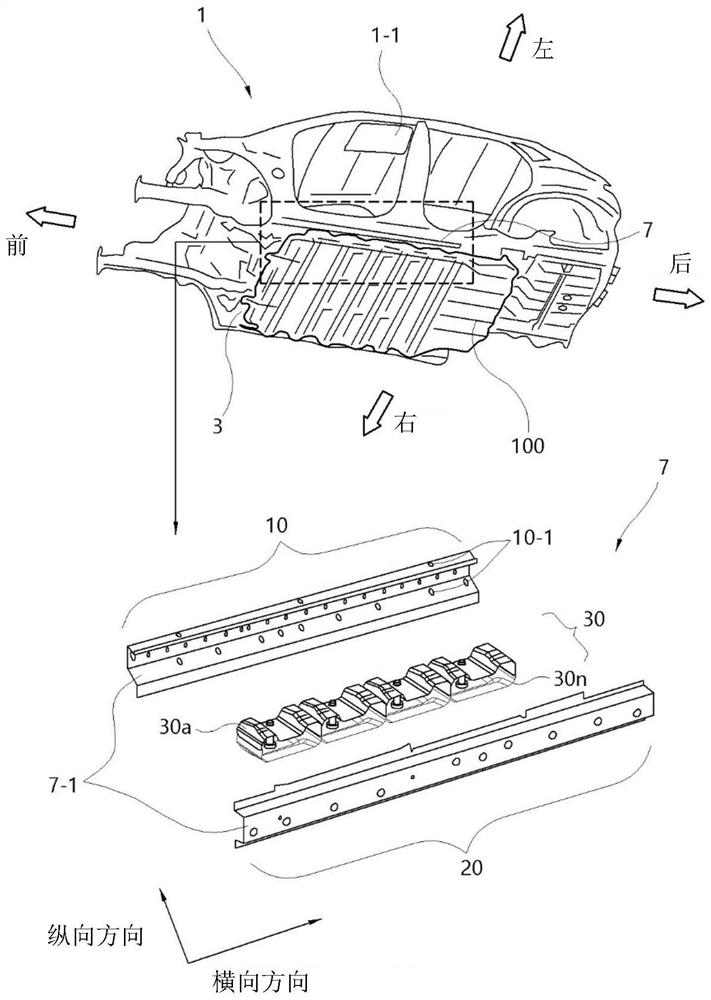

[0039] refer to figure 1 , the electric vehicle 1 includes side members 7 attached to lower portions of left and right side surfaces of the vehicle body frame 1-1.

[0040] Specifically, the vehicle body frame 1-1 includes a center floor 3 and a seat cross member 5 (refer to Figure 4 ). For example, the body shape body constitutes the body frame, the center floor 3 provides a place where the high voltage battery 100 is installed on its lower surface, and the seat cross member 5 supports lateral deformation of the side members 7 as a cross member in the center floor 3 .

[0041] Specifically, the central floor 3 forms a stepped portion (see Figure 4 to Figure 6 ), so that the side beams 7 are located on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com