Battery cell diaphragm drawstring buffering device and technology thereof

A diaphragm and buffering technology, which is applied in the field of battery diaphragm puller buffer devices, can solve the problems of surface wrinkles or warping of the flexible diaphragm, uneven distribution of flexible diaphragm materials, and the inability to keep the film pulling speed completely consistent in real time and continuously. To achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

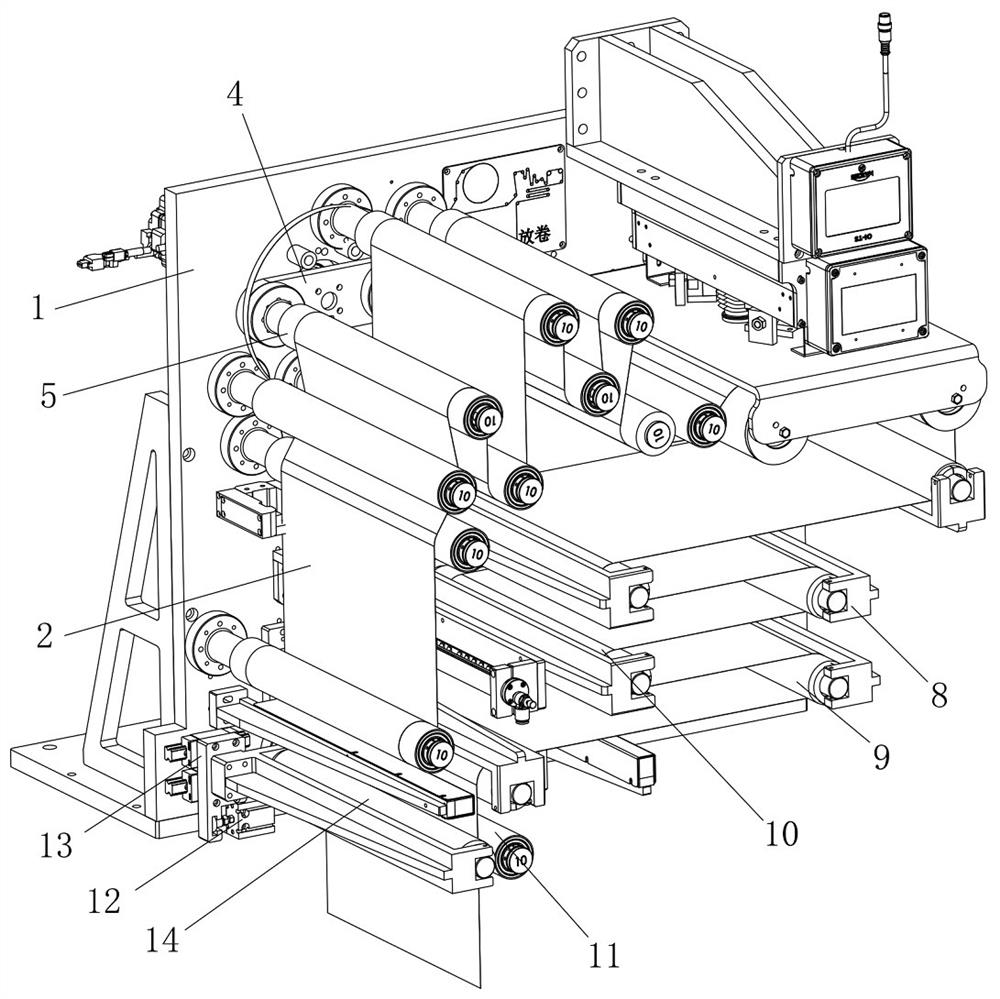

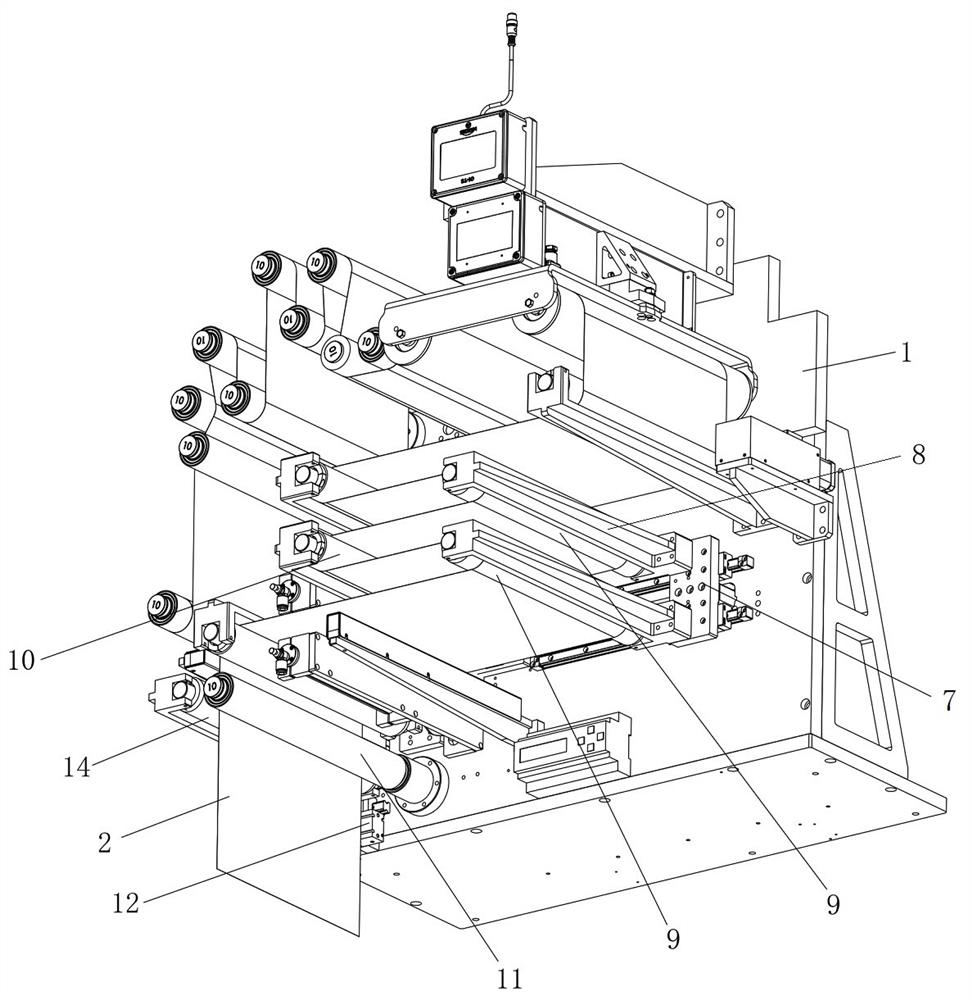

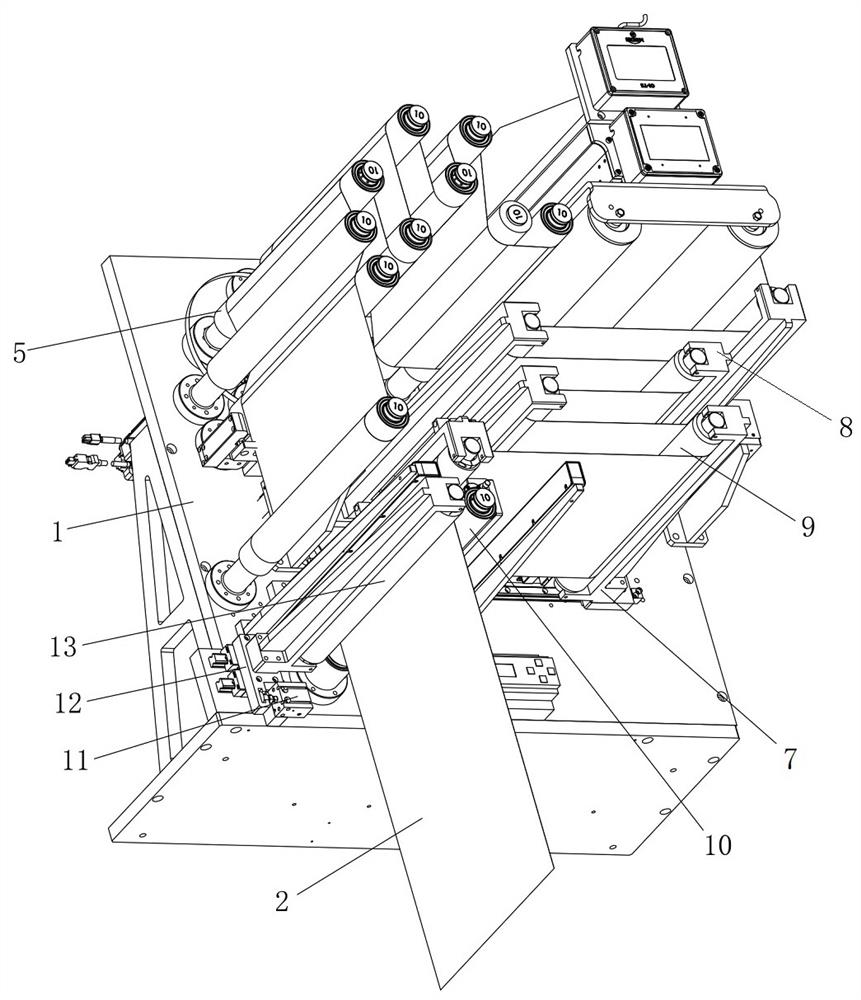

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] Such as Figure 1 to Figure 7 As shown, the technical solution adopted by the present invention is as follows: a cell diaphragm pull belt buffering device, including a vertically arranged support plate 1, on which the support plate 1 is rotatably and vertically provided with at least two tensioning rollers, and also includes a set The pull belt assembly, the diaphragm buffer assembly and the pressure belt assembly on the support plate 1, the belt-shaped diaphragm 2 passes through the pull belt assembly, the diaphragm buffer assembly and the pressure belt assembly in sequence; the above pull belt assembly includes two pulling rollers arranged at intervals 5. The two pulling rollers 5 are respectively connected to the two ends of the connecting plate 4. The diaphragm 2 passes through the two pulling rollers 5 in turn and is tensioned by the pulling rollers 5. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com