Flame-retardant process for chemical fabric

A technology of chemical fiber cloth and process, which is applied in the direction of fiber treatment, heating/cooling fabric, textile and paper making, etc. It can solve the problems of chemical fiber cloth such as poor heat resistance, flammability, loss of life and property, and achieve the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

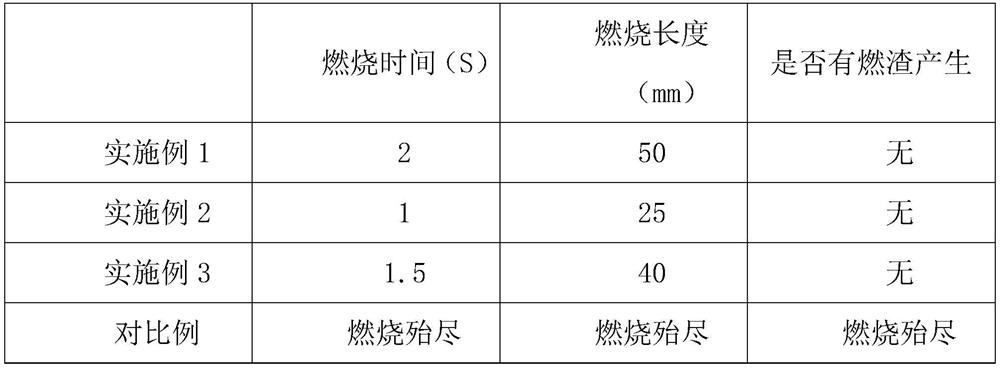

Examples

Embodiment 1

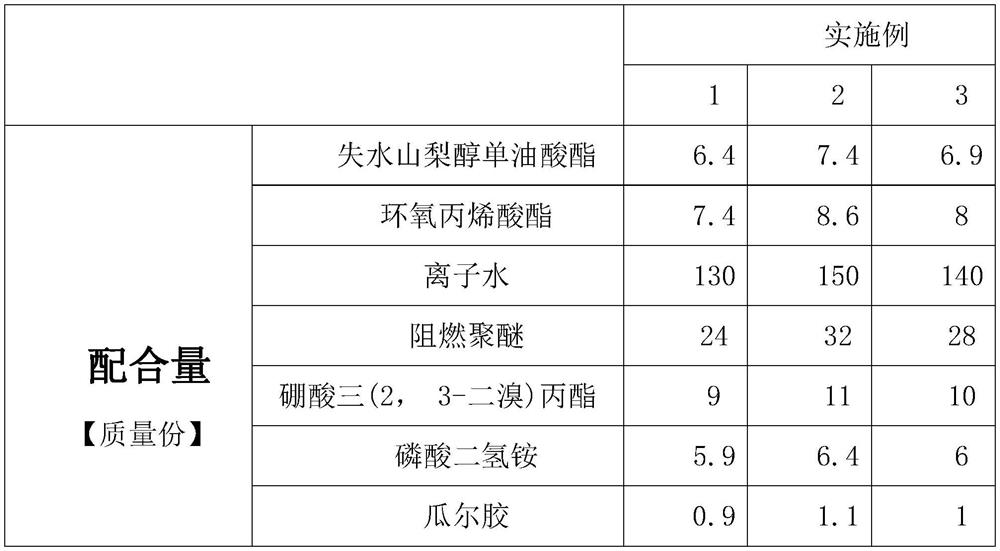

[0026] A flame-retardant process for chemical fiber cloth, comprising the following process steps:

[0027] S1. Pretreatment of chemical fiber cloth: arrange the chemical fiber in the cloth setting machine, and perform pre-setting treatment under the preset conditions of temperature 130°C and vehicle speed 11m / min;

[0028] S2. Preparation of flame retardant finishing agent: add sorbitan monooleate and epoxy acrylate into deionized water, stir evenly at low speed, then add flame retardant polyether, boric acid tris(2,3- Dibromo)propyl ester and ammonium dihydrogen phosphate, after stirring at a low speed of 120r / min, finally add guar gum and stir at a high speed of 340r / min to obtain a flame retardant finishing agent;

[0029] S3. Padding of chemical fiber cloth: immerse the chemical fiber cloth after pre-setting treatment in S1 into a container loaded with a flame retardant finishing agent for padding treatment. The temperature of the flame retardant finishing agent in the co...

Embodiment 2

[0043] A flame-retardant process for chemical fiber cloth, comprising the following process steps:

[0044] S1. Pretreatment of chemical fiber cloth: arrange the chemical fiber in the cloth setting machine, and perform pre-setting treatment under the preset conditions of temperature 150°C and vehicle speed 12m / min;

[0045] S2. Preparation of flame retardant finishing agent: add sorbitan monooleate and epoxy acrylate into deionized water, stir evenly at low speed, then add flame retardant polyether, boric acid tris(2,3- Dibromide) propyl ester, ammonium dihydrogen phosphate, after stirring evenly at a low speed of 140r / min, finally add guar gum and stir evenly at a high speed of 420r / min to obtain a flame retardant finishing agent;

[0046] S3. Padding of chemical fiber cloth: dipping the chemical fiber cloth after pre-setting treatment in S1 into a container loaded with a flame retardant finishing agent for padding treatment. The temperature of the flame retardant finishing a...

Embodiment 3

[0060] A flame-retardant process for chemical fiber cloth, comprising the following process steps:

[0061] S1. Pretreatment of chemical fiber cloth: arrange the chemical fiber in the cloth setting machine, and carry out pre-setting treatment under the preset conditions of temperature 140°C and vehicle speed 11.5m / min;

[0062] S2. Preparation of flame retardant finishing agent: add sorbitan monooleate and epoxy acrylate into deionized water, stir evenly at low speed, then add flame retardant polyether, boric acid tris(2,3- Dibromide) propyl ester, ammonium dihydrogen phosphate, after stirring at a low speed of 130r / min, finally add guar gum and stir at a high speed of 380r / min to obtain a flame retardant finishing agent;

[0063] S3. Padding of chemical fiber cloth: immerse the chemical fiber cloth after pre-setting treatment in S1 into a container loaded with a flame retardant finishing agent for padding treatment. The temperature of the flame retardant finishing agent in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com