Cross roof beam supporting and reinforcing formwork system and construction method thereof

A technology of formwork system and support system, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, formwork/formwork components, etc., which can solve the problem of unfavorable repeated recycling and non-conformity with energy conservation and environmental protection , template damage, etc., to achieve good reinforcement effect, high positioning, and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

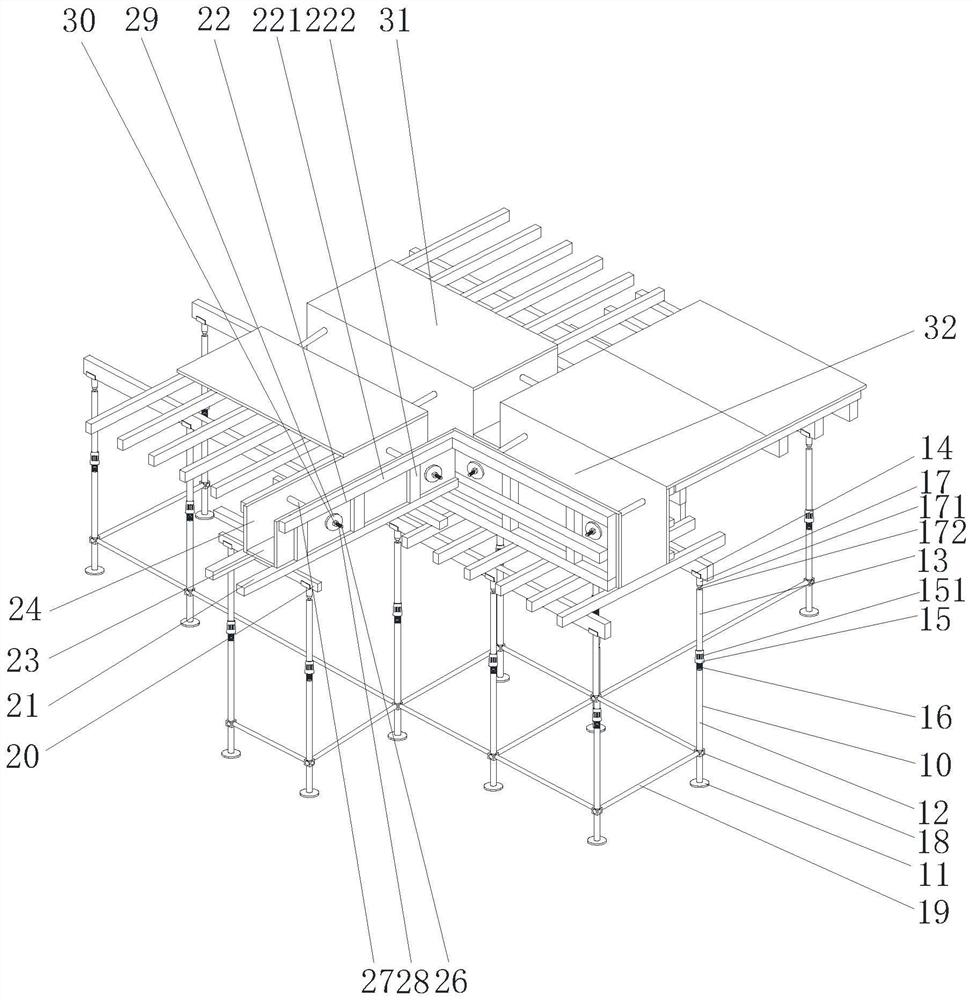

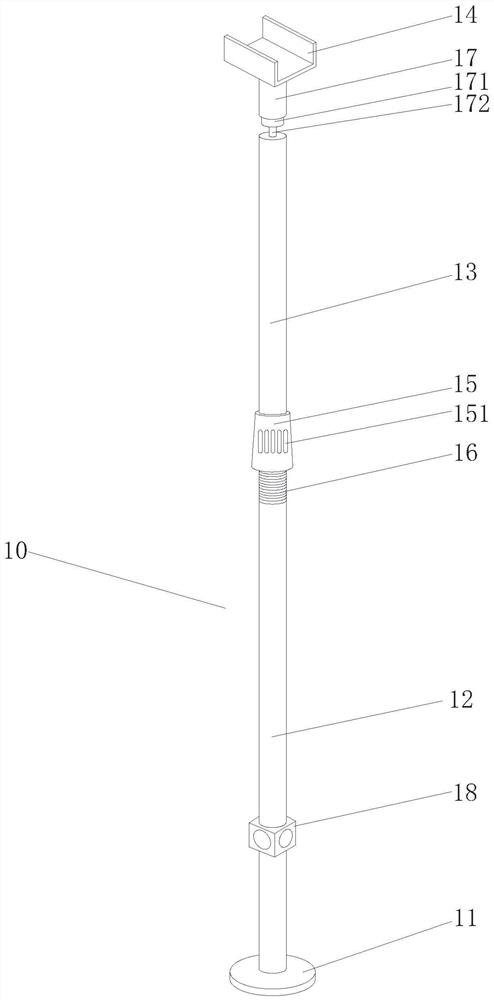

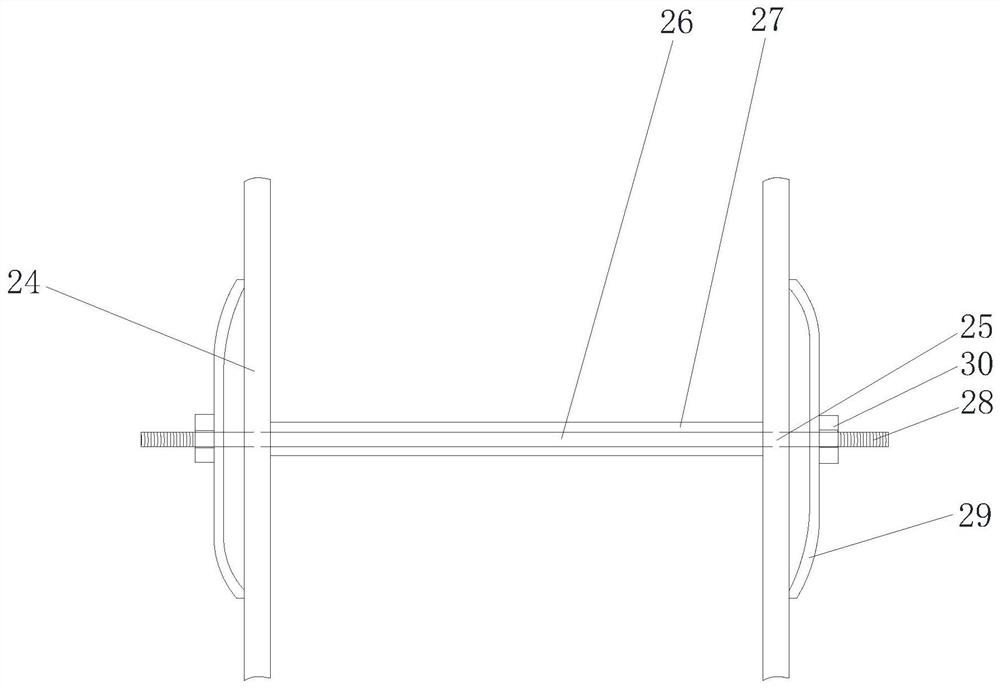

[0031] See Figure 1-4 The present invention provides a technical solution: a cross-housing beam support reinforcing template system, including a support system, a support system including adjustable support rod 10, adjustable support rod 10 including a base 11, a fixed bar 12, a regulating rod 13, and a recess The trough top via 14, the lower end of the adjustment lever 13 is provided with a threaded sleeve 15, and the end portion of the fixing rod 12 is provided with a thread I16, and the threaded sleeve 15 is mounted, and the top portion of the adjustment rod 13 is provided with a rotating shaft member. 17. The groove top via 14 is integrated with a rotating shaft member 17, and the lower portion of the fixing rod 12 is provided with a cross-sleeve member 18, and the fixed rod 12 is mounted with a rod 19, a groove top. There is a number of main bone rods 20 on the top of the reel member, and the main bone rod 20 is laid, and the secondary centroid 21 is provided on the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com