Vacuum pumping system

A vacuum system, vacuum pump technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve problems such as insufficient sealing performance, infiltration of toxic and harmful gases or flammable and explosive gases, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the application and the technical features in the embodiments can be combined with each other. Undue Limitation of This Application.

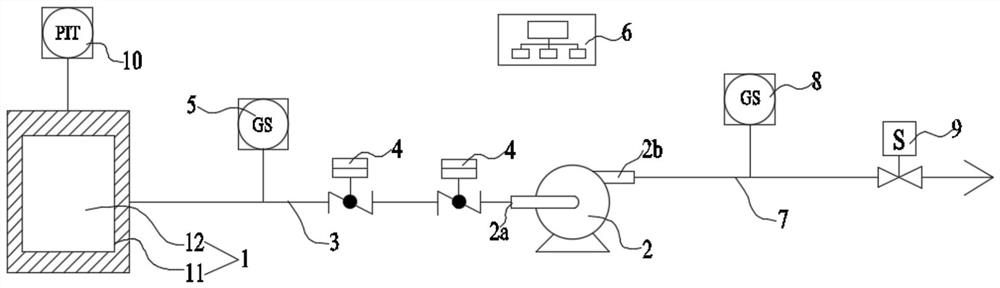

[0024] The embodiment of the present application provides a pumping vacuum system, please refer to figure 1 , including: a container 1 , a vacuum pump 2 , a first exhaust pipeline 3 , a front valve 4 , a first gas detector 5 and a control system 6 .

[0025] The container 1 includes a vacuum chamber 11 and a medium chamber 12. The medium chamber 12 is used to hold dangerous gas, wherein the dangerous gas includes poisonous or harmful gas or flammable and explosive gas.

[0026] Exemplary, toxic and harmful gases include but not limited to CO (carbon monoxide), BF 3 (boron trifluoride), Hg (mercury vapor), Rn (radon gas), etc.

[0027] Exemplary, flammable and explosive gases include but not limited to H 2 (hydrogen), CH 4 (methane), C 2 h 4 (ethylene), C 2 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com