Laser photoelectric rapid detection device and method for polluted grains and infected grains

A detection device and laser light source technology, applied in the fields of grain storage, production and transportation, can solve the problems of detection accuracy and interference, and achieve the effect of good detection accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

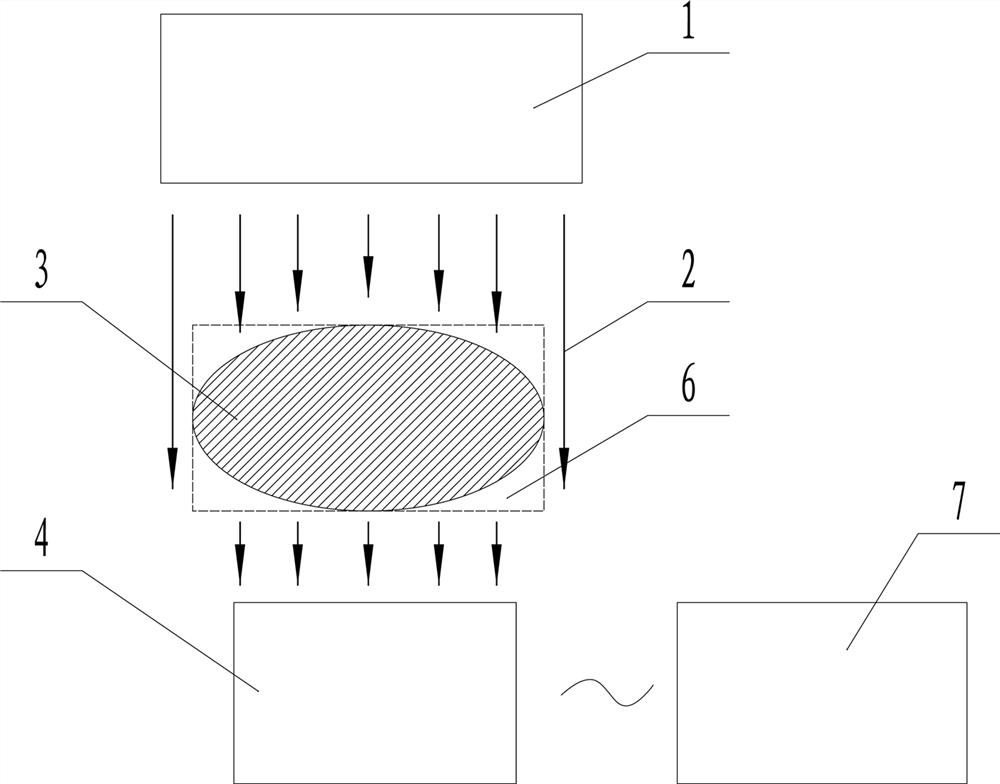

[0043] Such as figure 1 As shown, a laser photoelectric rapid detection device for food pollution and diseased grains includes a laser light source 1, a food detection position 6, a photodetector 4 and a processor module 7;

[0044] The laser light source 1 and the photodetector 4 are oppositely arranged on both sides of the grain detection position 6, and the light emitted by the laser light source 1 passes through the grain detection position 6 and is irradiated on the receiving end of the photodetector 4. The detector 4 is connected to the processor module 7 . The projected area of the peripheral boundary of the space to be measured of the food detection position 6 in the direction of light irradiation covers the boundary of the receiving end of the photodetector 4 .

[0045] In a preferred embodiment, the light emitted by the laser light source 1 is a parallel laser beam 2, which can ensure the stability and uniformity of the output light.

[0046] The detection method...

Embodiment 2

[0053] The main difference between this embodiment and embodiment 1 is:

[0054] The laser wavelength emitted by the laser light source is 550-750nm.

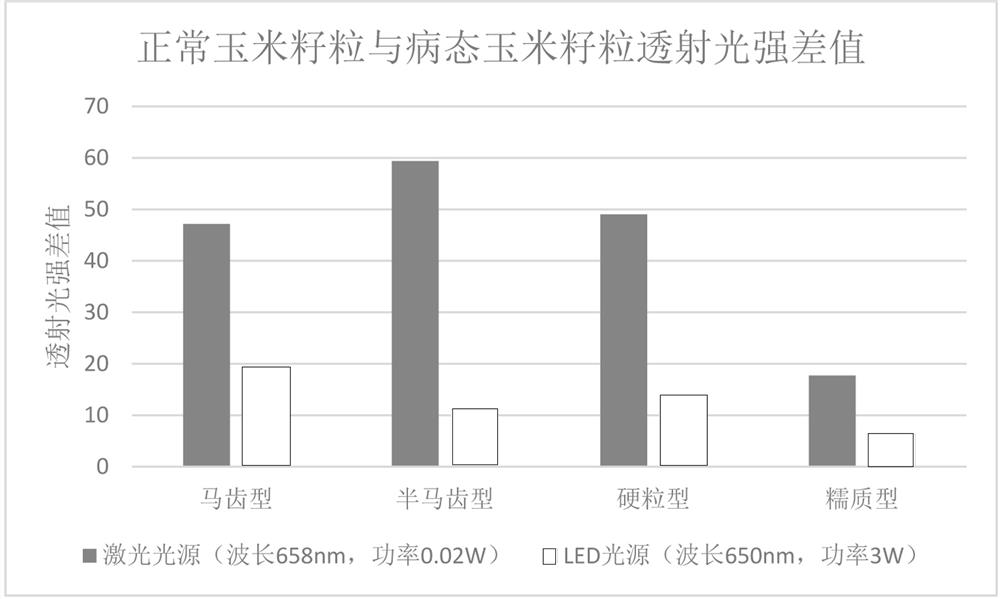

[0055] Such as Figure 4 As shown, this figure illustrates the discrimination of the transmitted light intensity between normal corn grains and diseased corn grains under different wavelength light sources. The light source wavelength range is between 550nm and 980nm, and the difference rate is obvious.

[0056] The difference rate is calculated as (transmitted light intensity of normal grains-transmitted light intensity of diseased grains) / transmitted light intensity of diseased grains.

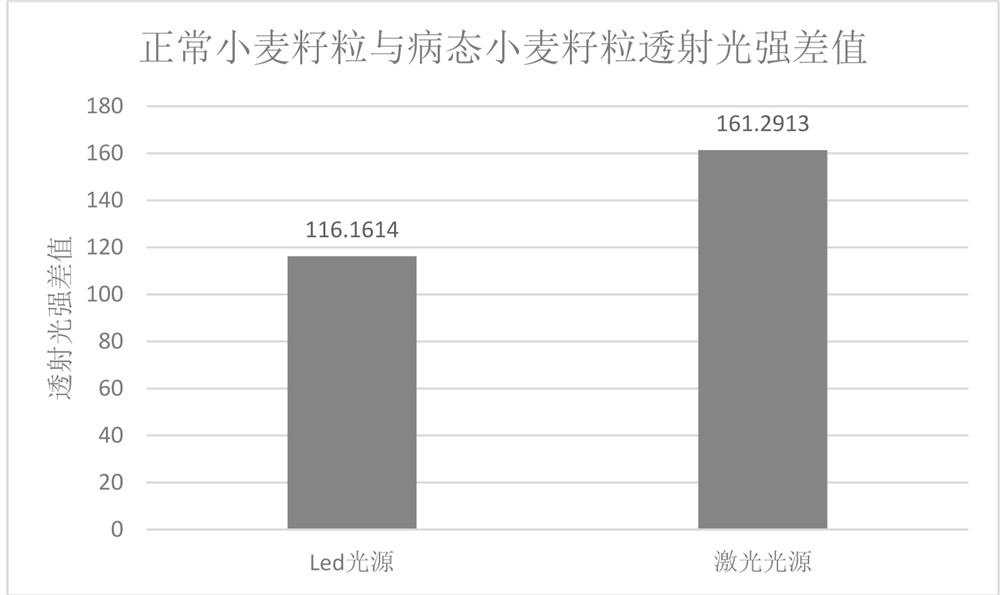

[0057] Such as Figure 5 As shown, this figure illustrates the discrimination of the transmitted light intensity of normal wheat grains and diseased grains under different wavelength light sources. The light source wavelength range is between 520nm and 800nm, and the difference rate is obvious.

[0058] Such as Image 6 with Figure 7 As...

Embodiment 3

[0061] Such as Figure 8 As shown, the grain detection position is an inclined grain flow channel 5, under which the grain flow channel 5 is provided with a slit or slot for installing the photodetector 4, and the laser light source 1 is installed in the grain flow channel 5 above.

[0062] The main purpose of this embodiment is to detect the grain flow one by one in the case of mass detection, so as to improve the detection efficiency.

[0063] Preferably, the emission direction of the laser light source is perpendicular to the grain flow channel, and the receiving direction of the photodetector is perpendicular to the grain flow channel, so as to ensure the stability of light emission and reception.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com