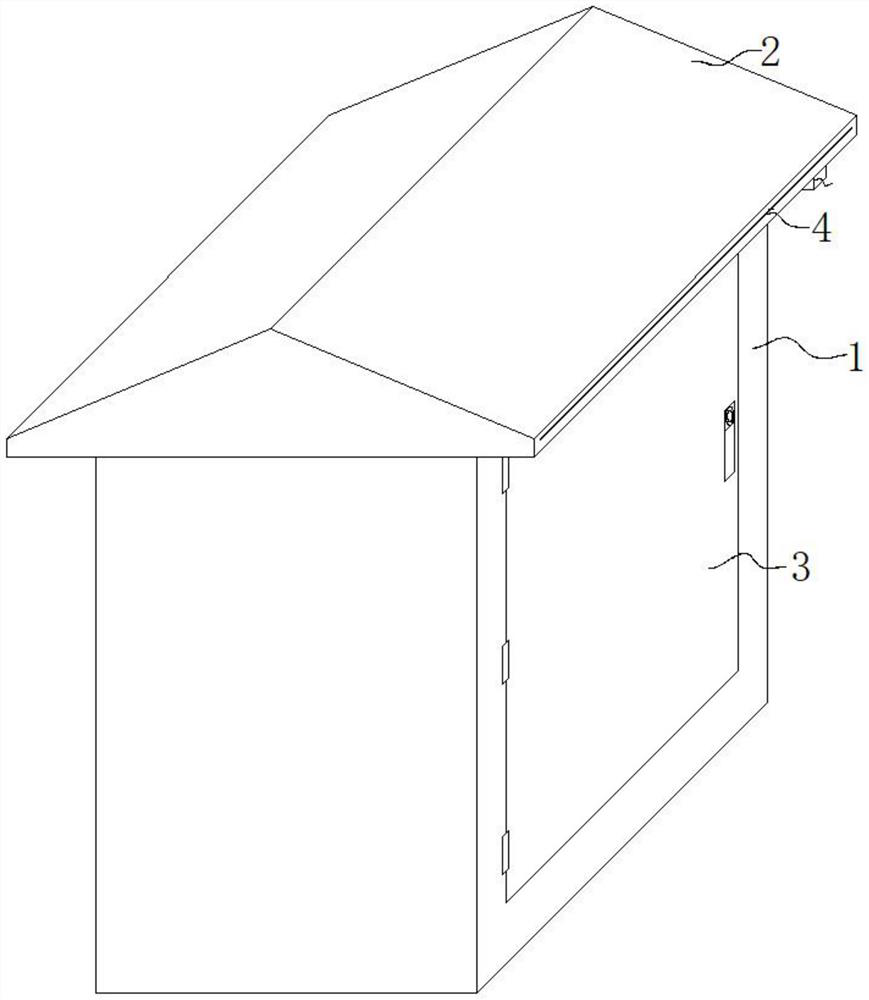

Prefabricated transformer substation with protective device

A technology of prefabricated substations and protective devices, which is applied in distribution substations, substations/distribution device shells, substations/switch layout details, etc., and can solve the problem of unfavorable prefabricated substation equipment heat dissipation safety and inability to effectively ensure heat dissipation Safety, easy to affect personnel's life and other issues, to achieve the effect of preventing moisture from entering the box, ensuring dryness, and reducing the pressure of filtration and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

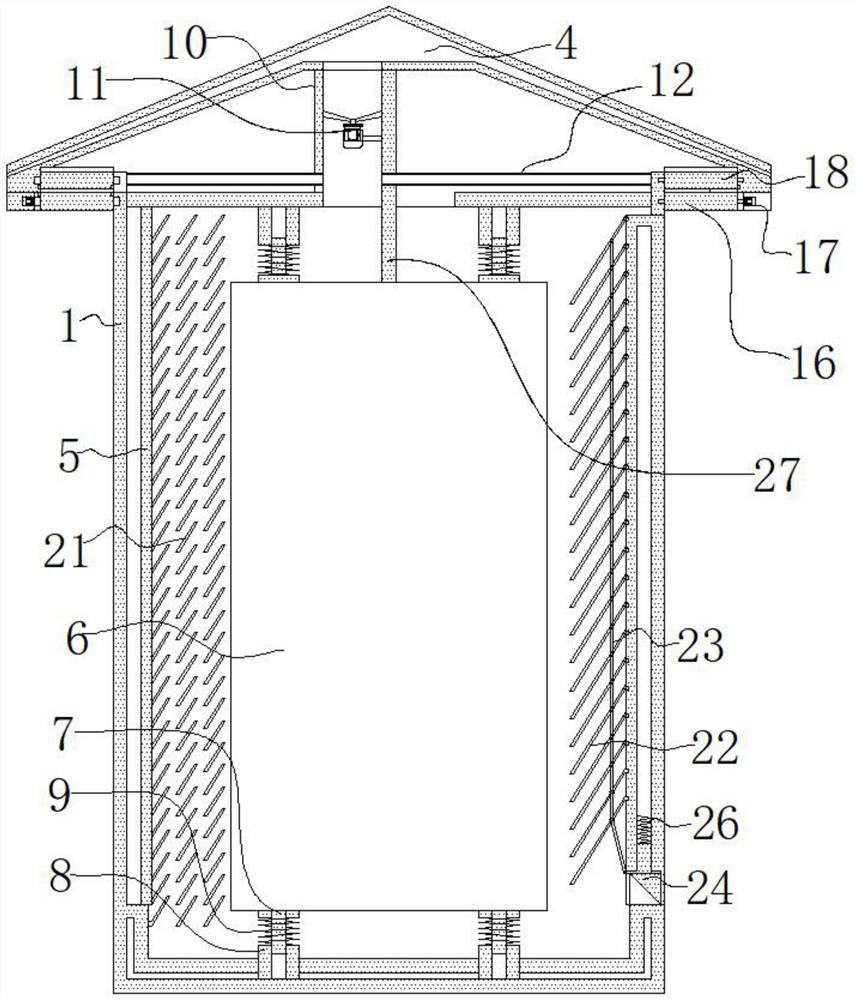

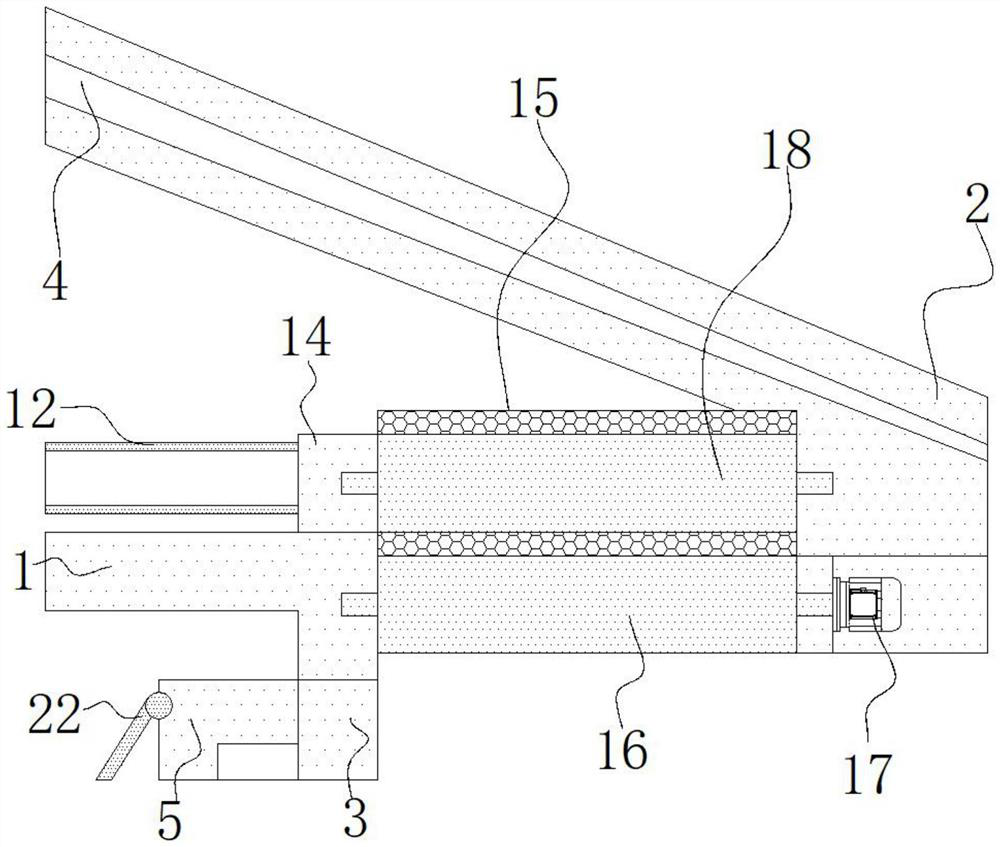

[0028] As a preferred embodiment of the present invention, the bottom of the air cylinder 10 passes through the box body 1 and communicates with the inside of the box body 1 , and the guide plate 27 is welded on the other side of the bottom of the air cylinder 10 .

[0029] As a preferred embodiment of the present invention, the top of the air duct 10 passes through the bottom of the roof 2 and communicates with the inner cavity 4, and the width of both ends of the inner cavity 4 is smaller than the width of the middle part of the inner cavity 4, which can When working, the fan one 11 works, and the left side of the box body 1 is generated by the air duct 10, so that the air is sucked into the bottom of the roof 2 through the gap between the top of the box body 1 and the bottom of both sides of the roof, The air is sucked into the top of the right side of the box body 1 through the tuyeres, the air flows down and flows around the bottom of the transformer 6 to the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com