Adhesive tape for semiconductor processing

A semiconductor and adhesive tape technology, applied in semiconductor/solid-state device manufacturing, adhesives, film/sheet adhesives, etc., can solve problems such as ring frame peeling, and achieve reliable bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

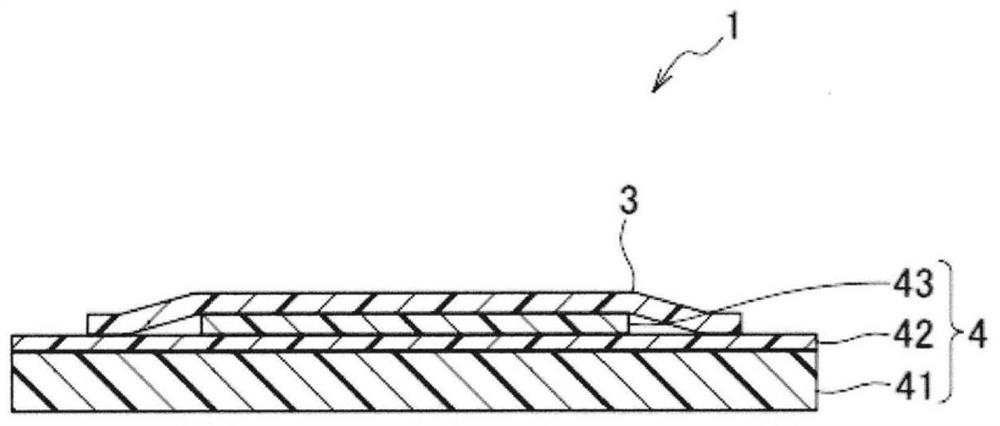

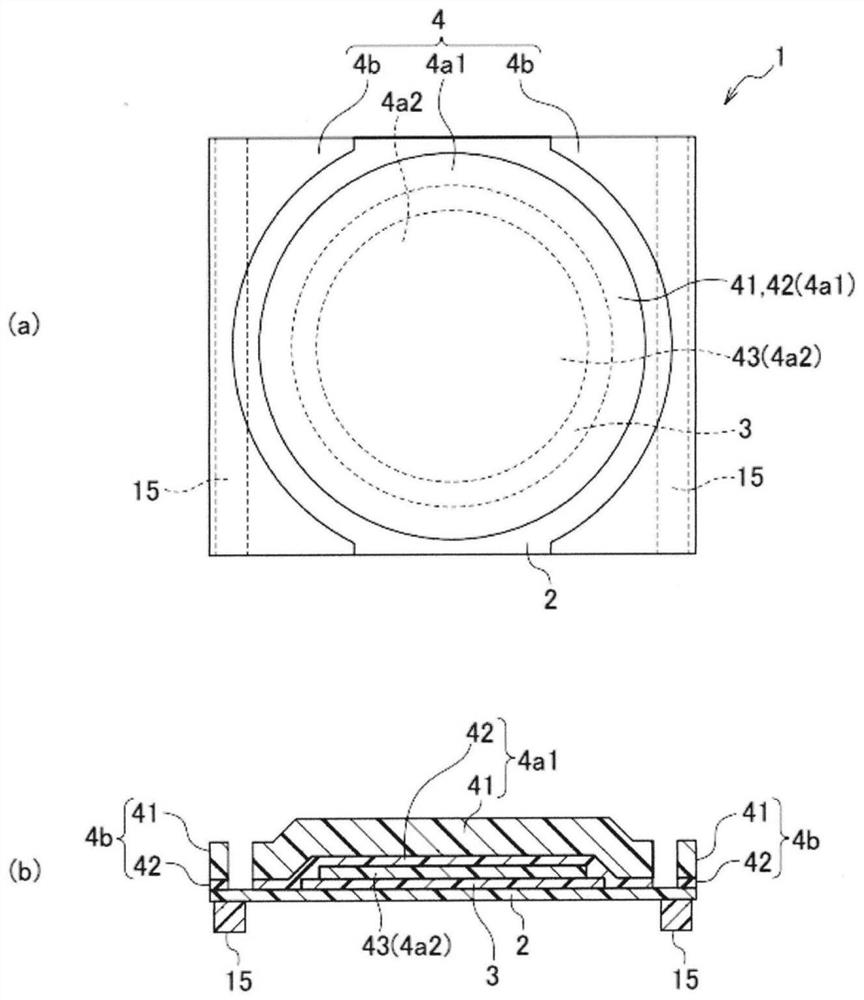

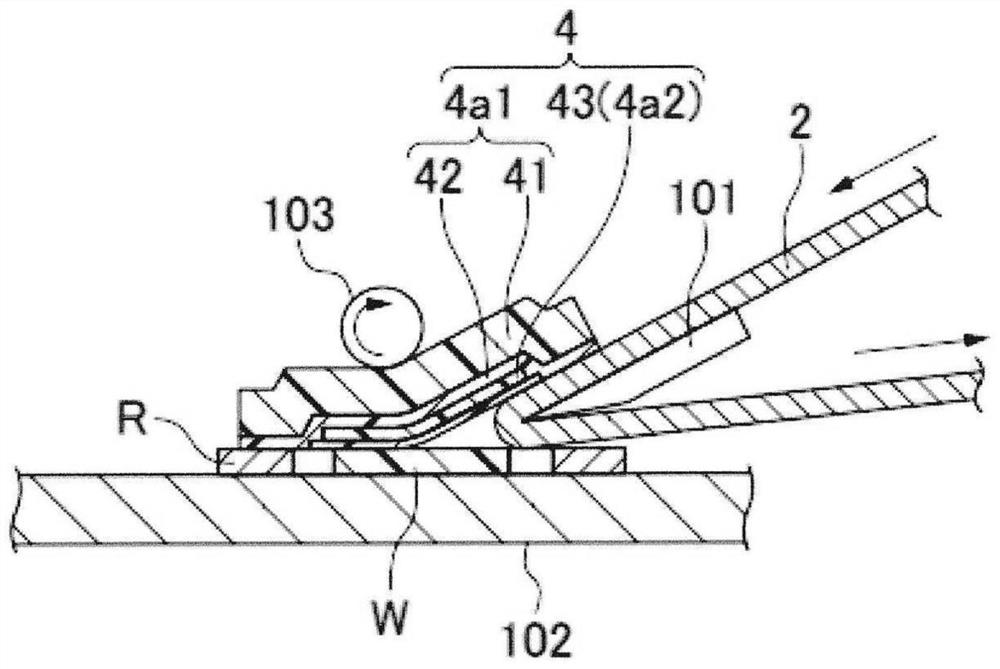

[0212] The adhesive composition A of this first adhesive layer was coated on the spacer made of the elongated polyethylene terephthalate film after the mold release treatment so that the thickness after drying became 5 μm. , after drying at 110° C. for 3 minutes, it was bonded to the base film A, and the adhesive sheet A in which the first adhesive layer was formed on the base film A was produced.

[0213] Then, on the spacer made of the cut sheet-shaped polyethylene terephthalate film after the mold release treatment, the adhesive composition A of the second adhesive layer is coated, and the dried The thickness becomes 10 μm, after drying at 110°C for 3 minutes, it is attached to the peeled polyethylene terephthalate film, and a plurality of second adhesive films are formed on the polyethylene terephthalate film. Adhesive sheet B of the mixture layer.

[0214] In addition, the adhesive composition A was applied to a substrate tape made of a long polyethylene terephthalate fi...

Embodiment 2

[0219] A sample of the adhesive tape for semiconductor processing of Example 2 was produced in the same manner as in Example 1 except that the adhesive composition A of the second adhesive layer was used instead of the adhesive composition A of the second adhesive layer. .

Embodiment 3

[0221] A sample of the adhesive tape for semiconductor processing of Example 3 was produced in the same manner as in Example 1, except that the adhesive composition A of the second adhesive layer was used instead of the adhesive composition A of the second adhesive layer. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com