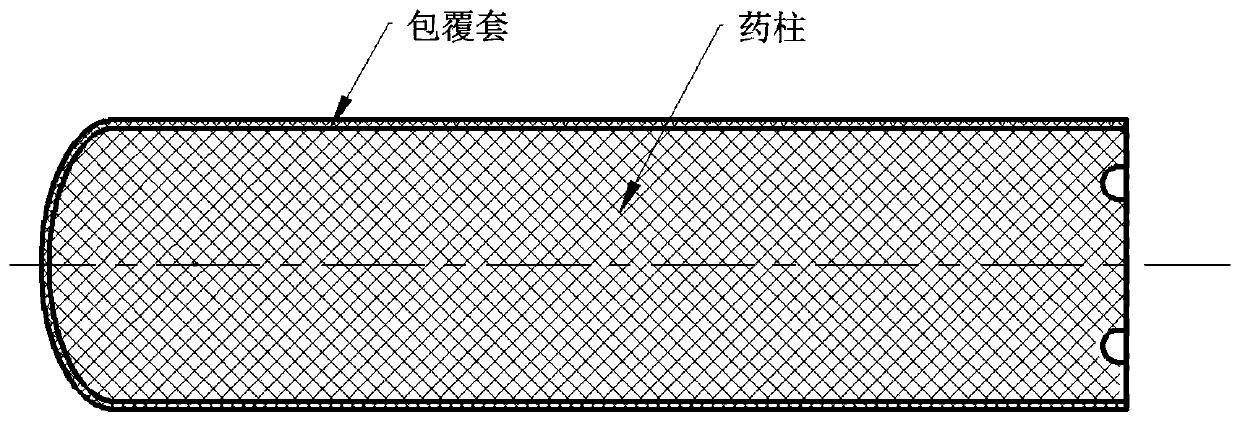

Solid rocket motor end surface grain coating structure and coating method thereof

A solid rocket and cladding structure technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of engine bursting and disintegration, low yield rate, high product process cost, etc., and achieve reliable bonding and high production efficiency , fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the solid rocket motor grain covering structure of this embodiment, the average thickness of the polyurea elastomer layer is 2.0 mm.

[0027] The coating method for implementing the solid rocket motor grain coating structure of this embodiment specifically includes the following steps:

[0028] (1) The formed powder column is fixed on the polyurea spraying rotary device, and the rotating speed of the polyurea spraying rotary device is set to be 5 seconds per circle;

[0029] (2) Use two injection devices to spray the A component of polyurea and the B component of polyurea into the spray chamber of the polyurea spraying rotary device, so that the components A and B are sprayed in the spray chamber. react to generate a polyurea mixture;

[0030] (3) Adjust the nozzle of the spray chamber and the spraying surface of the powder column to 350mm, make the spray chamber move up and down at a speed of 1m / s along the vertical direction, and the spraying surface of the spray ...

Embodiment 2

[0032] In the solid rocket motor grain covering structure of this embodiment, the average thickness of the polyurea elastomer layer is 1.8mm.

[0033] The coating method for implementing the solid rocket motor grain coating structure of this embodiment specifically includes the following steps:

[0034] (1) The formed powder column is fixed on the polyurea spraying rotary device, and the rotating speed of the polyurea spraying rotary device is set to be 4 seconds per circle;

[0035] (2) Use two injection devices to spray the A component of polyurea and the B component of polyurea into the spray chamber of the polyurea spraying rotary device, so that the components A and B are sprayed in the spray chamber. react to generate a polyurea mixture;

[0036] (3) Adjust the nozzle of the injection cavity and the spraying surface of the powder column to 300mm, make the injection cavity move up and down at a speed of 1.5m / s along the vertical direction, and the spraying surface of the...

Embodiment 3

[0038] The solid rocket motor grain coating structure of this embodiment has an average thickness of the polyurea elastomer layer of 2.2 mm.

[0039] The coating method for implementing the solid rocket motor grain coating structure of this embodiment specifically includes the following steps:

[0040] (1) The formed powder column is fixed on the polyurea spraying rotary device, and the rotating speed of the polyurea spraying rotary device is set to be 6 seconds per circle;

[0041] (2) Use two injection devices to spray the A component of the polyurea and the B polyurea component into the spray chamber of the polyurea spraying rotary device, so that the A component and the B component are sprayed in the spray chamber. react to generate a polyurea mixture;

[0042] (3) Adjust the nozzle of the spray chamber and the spraying surface of the powder column to 400mm, make the spray chamber move up and down along the vertical direction at a speed of 1m / s, and the spraying surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com