Special medical purpose thickening assembly based on konjac glucomannan and preparation method thereof

A konjac glucomannan and a special technology are applied in the field of thickening components for special medical purposes based on konjac glucomannan and the field of preparation thereof, which can solve the problems of being placed for too long and cannot be taken, and achieve slowing down the speed of digestion and absorption. Wide applicability, strong viscosity and thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method based on the thickening component for special medical use of KGM, comprising the following steps:

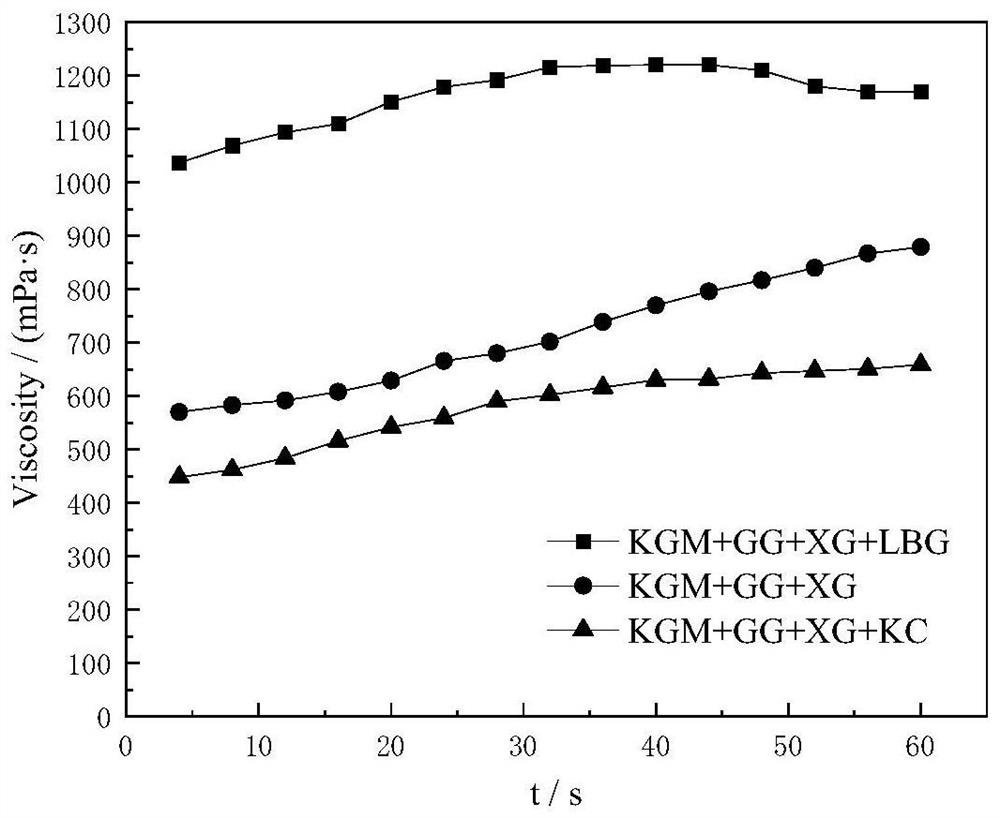

[0030] (1) Preparation of a composite thickener: use a vibrating sieving machine to sieve the raw materials; use a three-dimensional mixer to fully mix the raw materials to obtain a composite thickener. The raw materials include KGM, guar gum, xanthan gum, locust bean gum, and carrageenan; the screen of the vibrating screening machine is selected from 150 to 170 mesh screens; the rotating speed of the three-dimensional mixer is 32r / min, mixing The time is 4-6 minutes.

[0031] (2) Fully mix the compound thickener and maltodextrin with a dual-motion mixer to obtain a thickening component based on KGM for special medical purposes. The mixing time of the double-motion mixer is 8-12 minutes.

[0032] The brewing temperature of the thickening component when eating is 45-60°C. The viscosity of the thickening component ...

Embodiment 1

[0034] A method for preparing thickening components based on KGM for special medical purposes, comprising the following steps:

[0035] (1) Preparation of composite thickener: Use a vibrating screening machine with 170 mesh screens to screen the raw materials. According to mass percentage, the raw materials include KGM 21.7%, guar gum 3.3%, xanthan gum 3.3%, locust bean gum 3.3%, carrageenan 1.7%, use a three-dimensional mixer to fully mix the raw materials, the rotation speed is 32r / min, and the mixing time is 4min to obtain a composite thickener;

[0036] (2) Fully mix the compound thickener and maltodextrin with a double-motion mixer, the mass percentage of maltodextrin is 66.7%, and the mixing time is 8 minutes to obtain a thickening component based on KGM for special medical purposes.

[0037] The prepared thickening component based on KGM for special medical use has loose particles with an average particle size of 12 μm. There are many small holes on the surface and ther...

Embodiment 2

[0039] A method for preparing thickening components based on KGM for special medical purposes, comprising the following steps:

[0040](1) Preparation of composite thickener: Use a vibrating sieving machine with 170 mesh screens to sieve the raw materials. According to mass percentage, the raw materials include KGM 23.1%, guar gum 3.6%, xanthan gum 3.6%, locust bean gum 3.6%, carrageenan 1.8%, use a three-dimensional mixer to fully mix the raw materials, the rotation speed is 32r / min, and the mixing time is 4min to obtain a composite thickener;

[0041] (2) The compound thickener and maltodextrin were fully mixed with a double-motion mixer, the mass percentage of maltodextrin was 64.3%, and the mixing time was 9 minutes to obtain a thickening component based on KGM for special medical purposes.

[0042] The prepared product based on KGM thickening component for special medical use has loose particles, many small holes on the surface and certain depressions and wrinkles. Some s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Peak viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com