Preparation method of novel phosphorus-nitrogen flame retardant

A flame retardant and a new type of technology, applied in the field of flame retardants, can solve the problems of poor compatibility of phosphorene nanosheets, low addition amount, high flame retardant efficiency, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a novel phosphorus-nitrogen flame retardant, comprising the following steps:

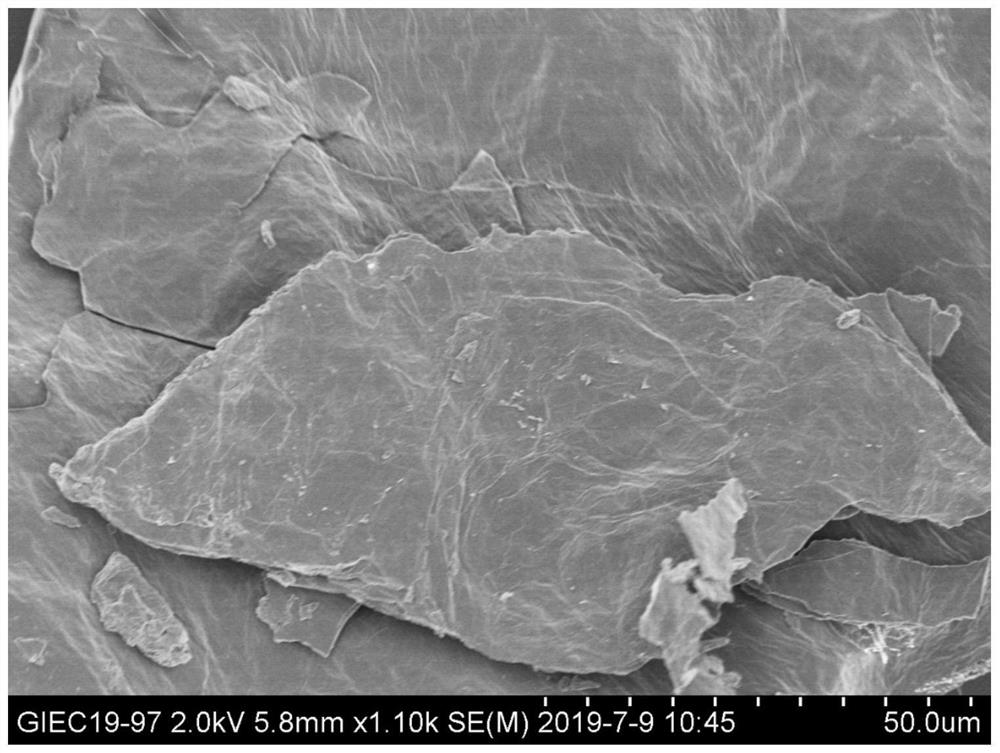

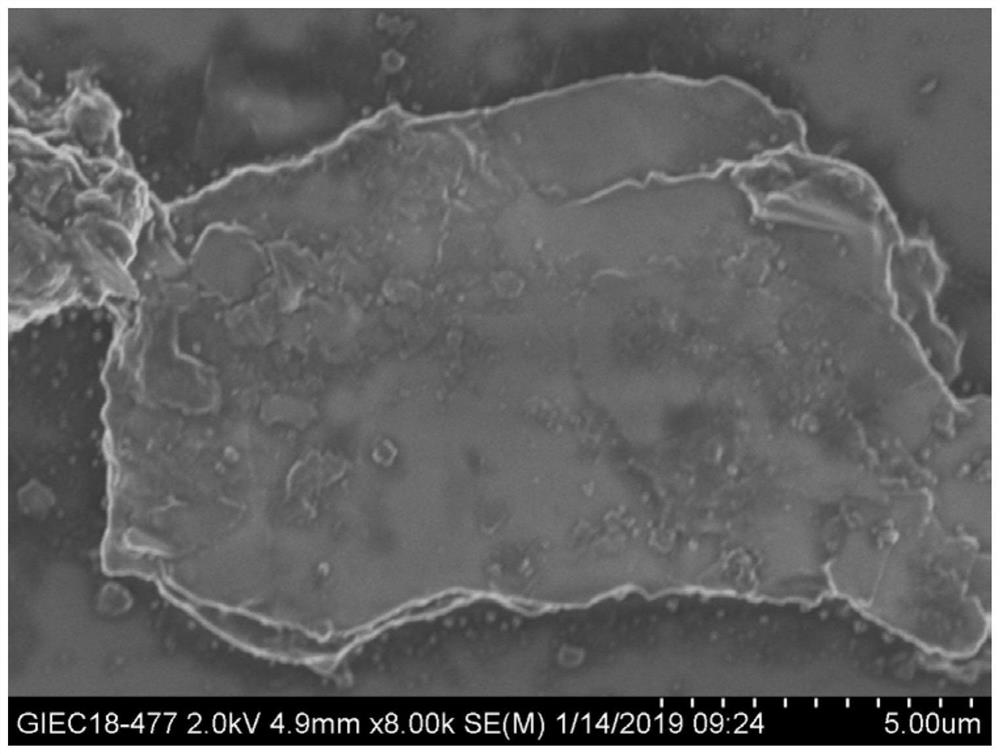

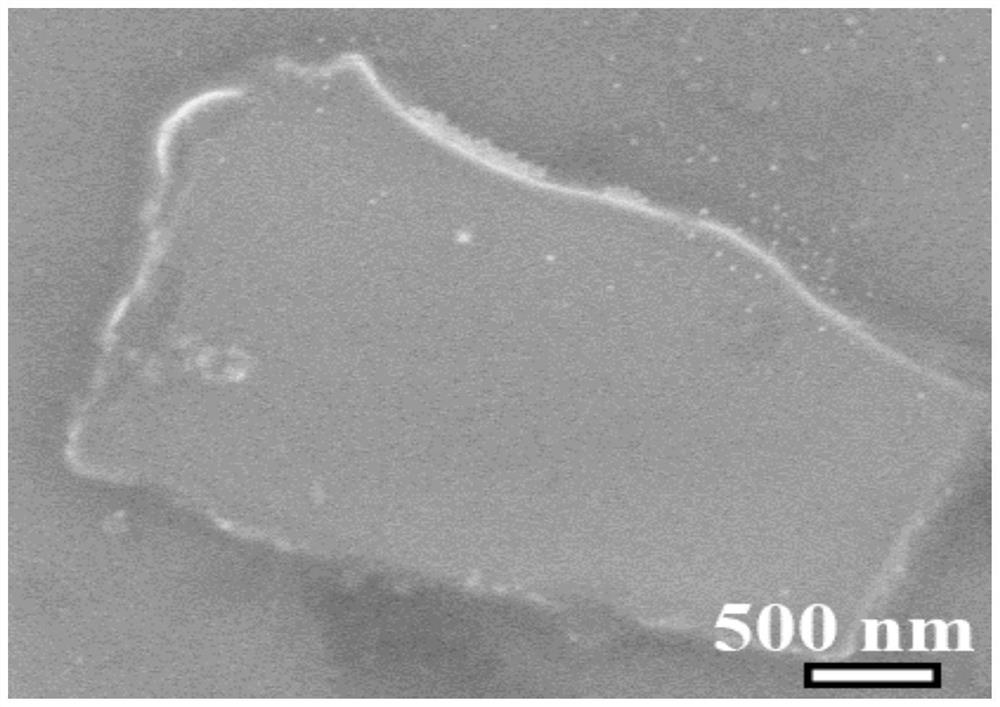

[0032] (1) Under the protection of nitrogen, 1.0g black phosphorus crystals and 20.0g urea were added in the ball mill jar, and then ball milled at a speed of 500r / min for 8 hours; after the ball mill finished, transfer the ball mill product to In a centrifuge tube, centrifuge at 1000r / min for 15 minutes to collect the upper layer suspension; centrifuge the upper layer suspension at 8000r / min for 30 minutes, collect the lower layer precipitate and dry it in vacuum at 140°C for 4 hours to obtain the amino graft Branched phosphorene nanosheets;

[0033] (2) Get 2.0g of melamine and add 30ml of deionized water, mechanically stir, and the rotating speed is 300r / min; then dropwise add 8.6ml (37%) of formaldehyde solution, and use the newly configured Na 2 CO 3 (10%) solution adjusts pH to 9, heats up to 80 DEG C, continues to stir for 30 minutes, obtains melamine-formalde...

Embodiment 2

[0036] A preparation method of a novel phosphorus-nitrogen flame retardant, comprising the following steps:

[0037] (1) Under the protection of nitrogen, 1.5g black phosphorus crystals and 40.0g urea were added to the ball mill jar, then ball milled at a speed of 600r / min for 12 hours; after the ball mill finished, transfer the ball mill product to In a centrifuge tube, centrifuge at 1500r / min for 20 minutes to collect the upper layer suspension; centrifuge the upper layer suspension at 6000r / min for 20 minutes, collect the lower layer precipitate and dry it in vacuum at 120°C for 5 hours to obtain the amino graft Branched phosphorene nanosheets;

[0038] (2) Get 4.0g of melamine and add 50ml of deionized water, mechanically stir, and the rotating speed is 400r / min; 2 CO 3 (10%) solution adjusts pH to 8, heats up to 60 ℃, continues to stir for 60 minutes, obtains melamine-formaldehyde prepolymer;

[0039] (3) Get 1.5g amino-grafted phosphorene nanosheets, add it to 20.0g m...

Embodiment 3

[0041] A preparation method of a novel phosphorus-nitrogen flame retardant, comprising the following steps:

[0042](1) Under the protection of nitrogen, 2.0g black phosphorus crystals and 60.0g urea were added in the ball mill jar, and then ball milled at a speed of 800r / min for 16 hours; after the ball mill finished, the ball mill product was transferred to In a centrifuge tube, centrifuge at 2000r / min for 10 minutes to collect the upper layer suspension; centrifuge the upper layer suspension at 5000r / min for 30 minutes, collect the lower layer precipitate and dry it in vacuum at 100°C for 8 hours to obtain the amino graft Branched phosphorene nanosheets;

[0043] (2) Take 5.0g of melamine and add 40ml of deionized water, stir mechanically at a speed of 300r / min; then add 17.9ml (37%) of formaldehyde solution dropwise, and use newly configured NaHCO 3 (10%) solution adjusts pH to 8, heats up to 50 ℃, continues to stir for 40 minutes, obtains melamine-formaldehyde prepolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com