Degradable mosquito net bag

A technology of mosquito nets and shares, applied in the direction of conjugated artificial filaments, flexible coverings, fiber chemical characteristics, etc., can solve the problems of increasing environmental pollution and resource consumption, increasing the burden of self-regulation of the ecological environment, and long time required, etc. problem, to achieve the effect of enhancing toughness, increasing service life and reducing oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

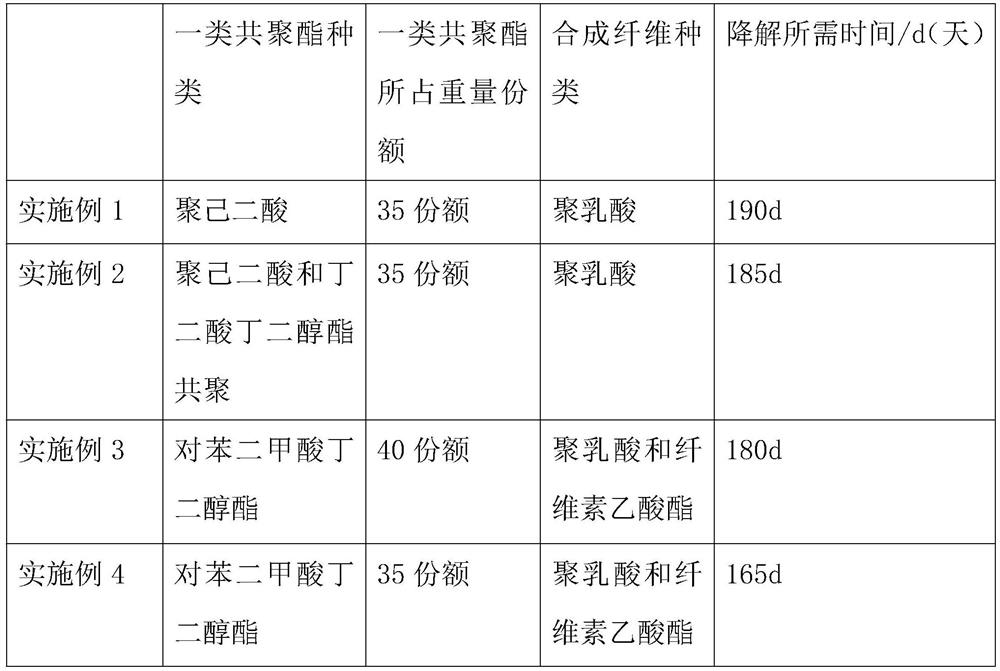

Embodiment 1

[0022] The invention provides a preparation method of a degradable mosquito net bag

[0023] a) Raw material preparation: prepare 25 parts of polylactic acid, 35 parts of polyadipate and 20 parts of acetylated starch:

[0024] b) Preparation of thermoplastic acetylated starch: add glycerin in a ratio of 1 to acetylated starch to the inside of acetylated starch, and perform uniform mixing operation, then store in airtight storage for 24 hours, and then melt at 180 degrees Celsius at a speed of 75r / min After mixing for 15 minutes, thermoplastic acetylated starch can be obtained, which is then stored for step c;

[0025] c) Preparation of braided spacers: thermoplastic acetylated starch, polylactic acid and polyadipic acid are mixed and melted to obtain a mixed material, and then the braided fibers are extruded through a twin-screw extruder, and naturally cooled until room temperature, Then organize and store, and carry out disinfection treatment;

[0026] d) Preparation of rei...

Embodiment 2

[0029] The invention provides a preparation method of a degradable mosquito net bag

[0030] a) Raw material preparation: prepare 25 parts of polylactic acid, 35 parts of polyadipate and succinate butylene glycol ester copolymerization and 20 parts of acetylated starch:

[0031] b) Preparation of thermoplastic acetylated starch: add glycerin in a ratio of 1 to acetylated starch to the inside of acetylated starch, and perform uniform mixing operation, then store in airtight storage for 24 hours, and then melt at 180 degrees Celsius at a speed of 75r / min After mixing for 15 minutes, thermoplastic acetylated starch can be obtained, which is then stored for step c;

[0032] c) Preparation of braided spacers: thermoplastic acetylated starch, polylactic acid, polyadipate and butylene succinate are copolymerized for mixing and melting operation to obtain a mixed material, and then the braided fibers are extruded through a twin-screw extruder, And carry out natural cooling operation ...

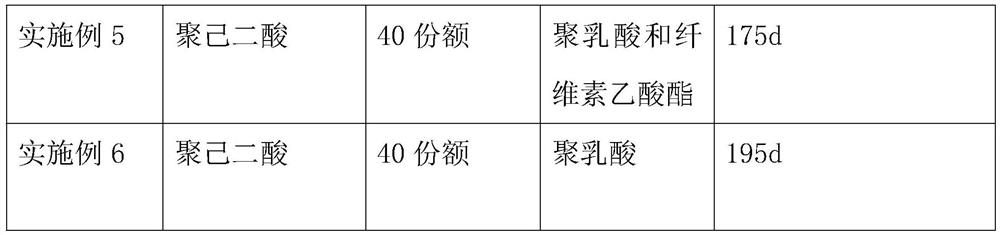

Embodiment 3

[0036] The invention provides a preparation method of a degradable mosquito net bag

[0037] a) Raw material preparation: prepare 20 parts of polylactic acid and cellulose acetate, 40 parts of butylene terephthalate and 35 parts of acetylated starch:

[0038] b) Preparation of thermoplastic acetylated starch: add glycerin in a ratio of 1 to acetylated starch to the inside of acetylated starch, and perform uniform mixing operation, then store in airtight storage for 24 hours, and then melt at 180 degrees Celsius at a speed of 75r / min After mixing for 15 minutes, thermoplastic acetylated starch can be obtained, which is then stored for step c;

[0039] c) Preparation of braided spacer: thermoplastic acetylated starch, polylactic acid, cellulose acetate and butylene terephthalate are mixed and melted to obtain a mixed material, and then the braided fiber is extruded through a twin-screw extruder , and carry out natural cooling operation until room temperature, then organize and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com