Patents

Literature

33 results about "Starch formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starch is stored in chloroplasts in the form of granules and in such organs as the roots of the tapioca plant; the tuber of the potato; the stem pith of sago; and the seeds of corn, wheat, and rice.

Preparation method of corn starch-fatty acid compound having V-shaped crystal structure

InactiveCN104757369AImprove hydrophobicityImprove acid resistanceFood preparationWater bathsFreeze-drying

Owner:QINGDAO AGRI UNIV

Multi-flavor purple sweet potato crystal noodles processing method

Owner:ANHUI SANXIONGDI POTATO IND

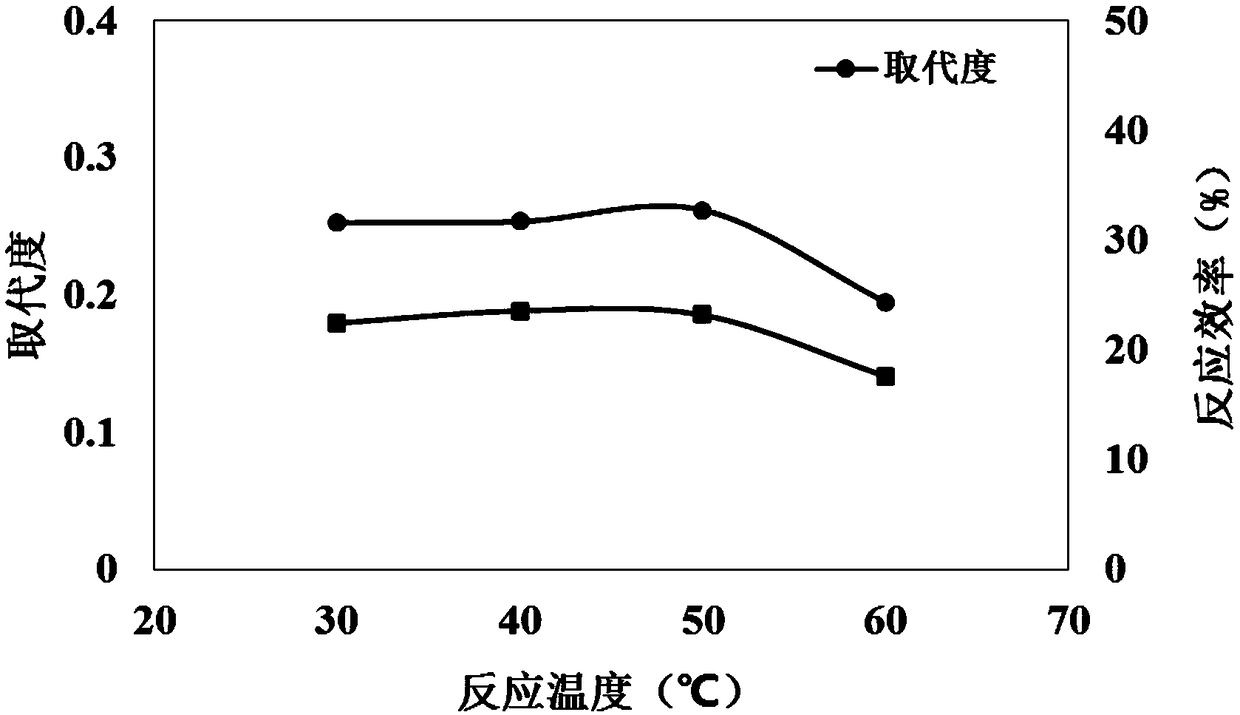

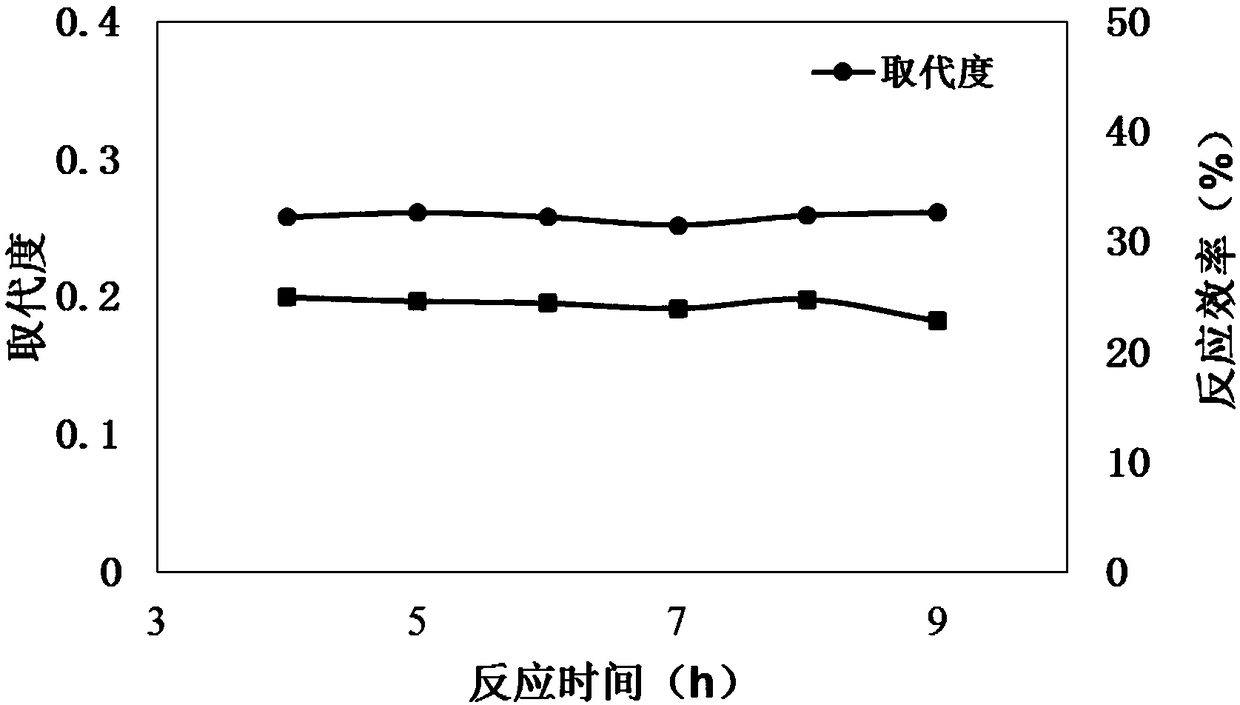

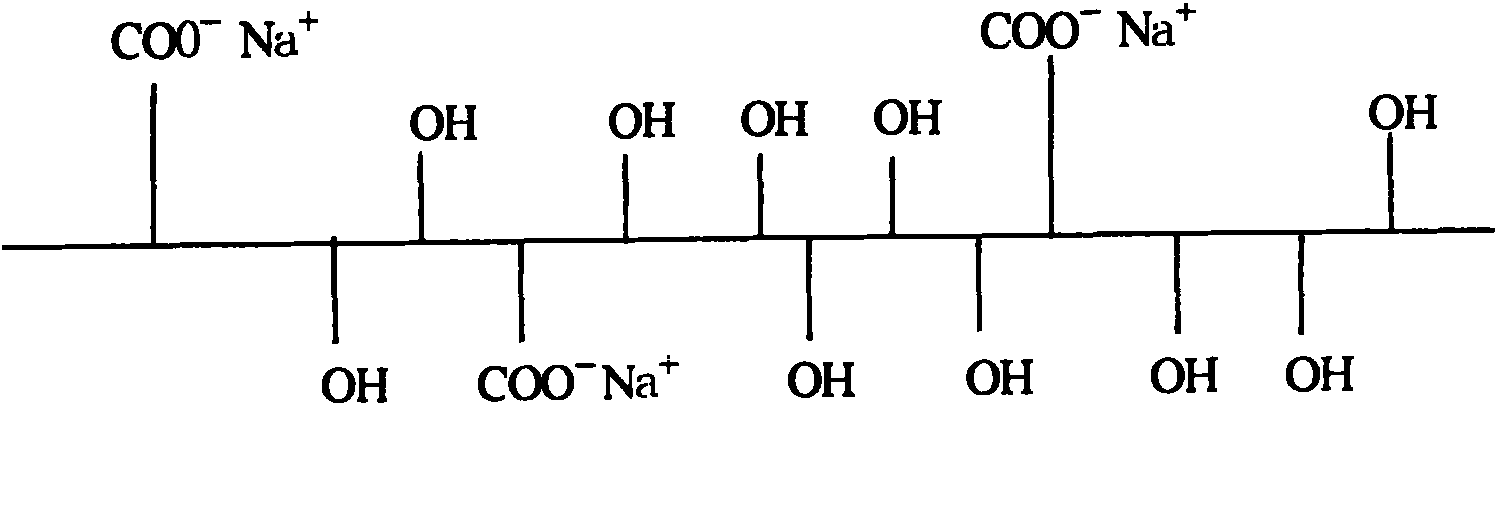

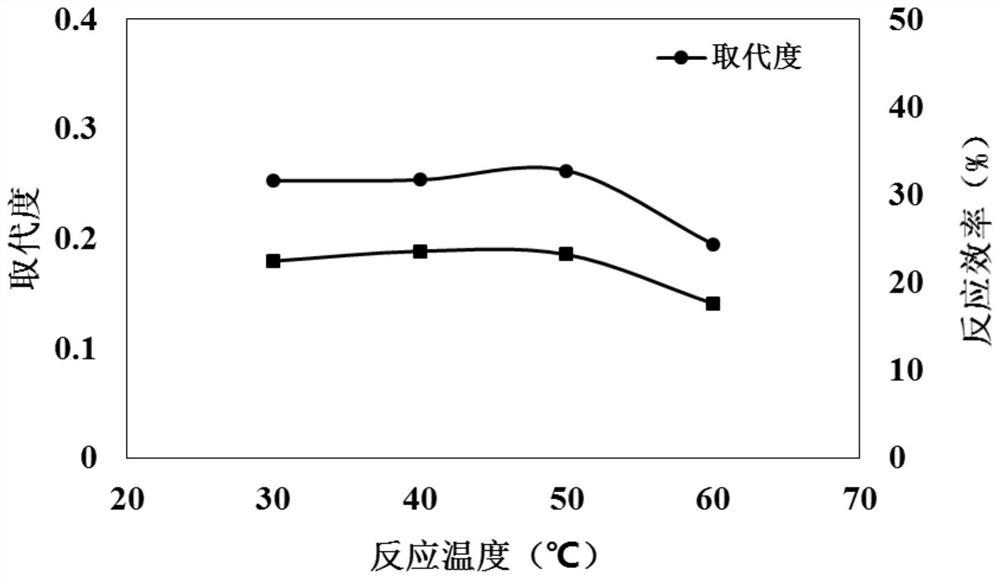

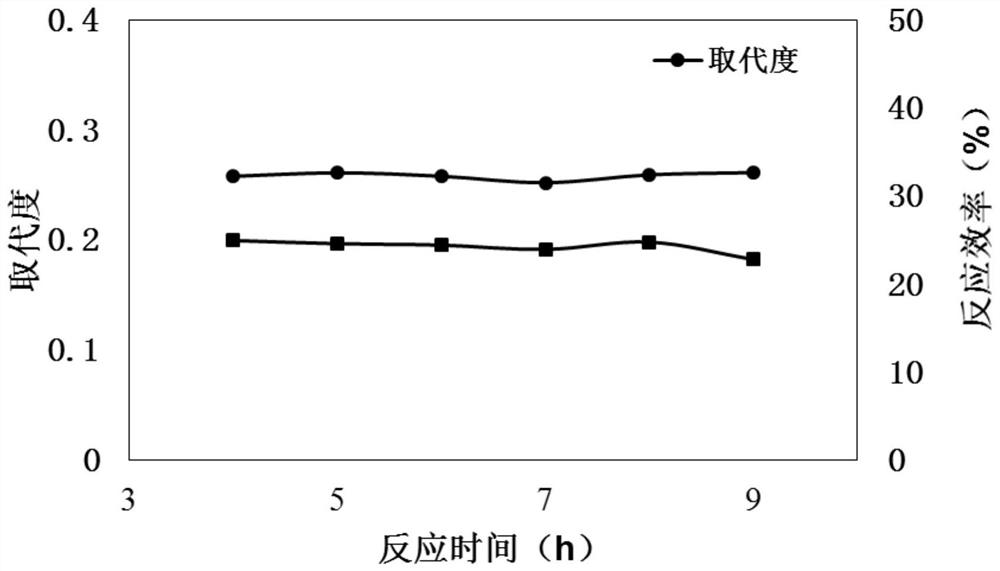

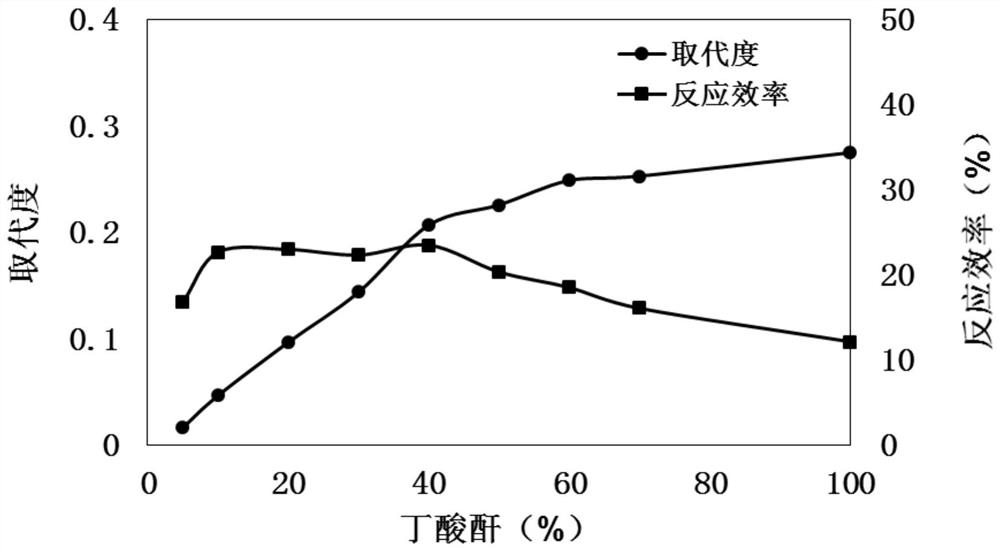

Butyrate starch preparing method

ActiveCN109400725ASolve the problem of irritating odor and volatilePrevent volatilizationFood ingredient functionsButyric anhydrideLarge intestine

The invention discloses a butyrate starch preparing method and belongs to the technical fields of preparation and application of modified starch and deep processing of agricultural products. Accordingto the butyrate starch preparing method, starch serve as the principal raw material for esterification with butyric anhydride to achieve stabilization of butyric acid and small releasing of the butyric acid in gastric juice; resistant starch prepared through esterification of the butyric acid and the starch can well avoid being absorbed in small intestines, resist digestion by enzymes secreted bybrush borders, selectively release micromolecular effective load in large intestines; fermented by enteric microorganisms, the resistant starch can produce more short-chain fatty acids and probiotics, thereby improving the bioavailability of the butyric acid and expanding the application range of the starch. Compared with other butyric acid products, the butyrate starch is odorless and can be esterified into the resistant starch to convey the butyric acid to the rear end of the intestines; the butyrate starch can be fermented by the enteric microorganisms and decomposed by bacterial esteraseinto butyric acid and other short-chain fatty acids and increase the content of the probiotics, thereby belonging to probiotic products.

Owner:JIANGNAN UNIV

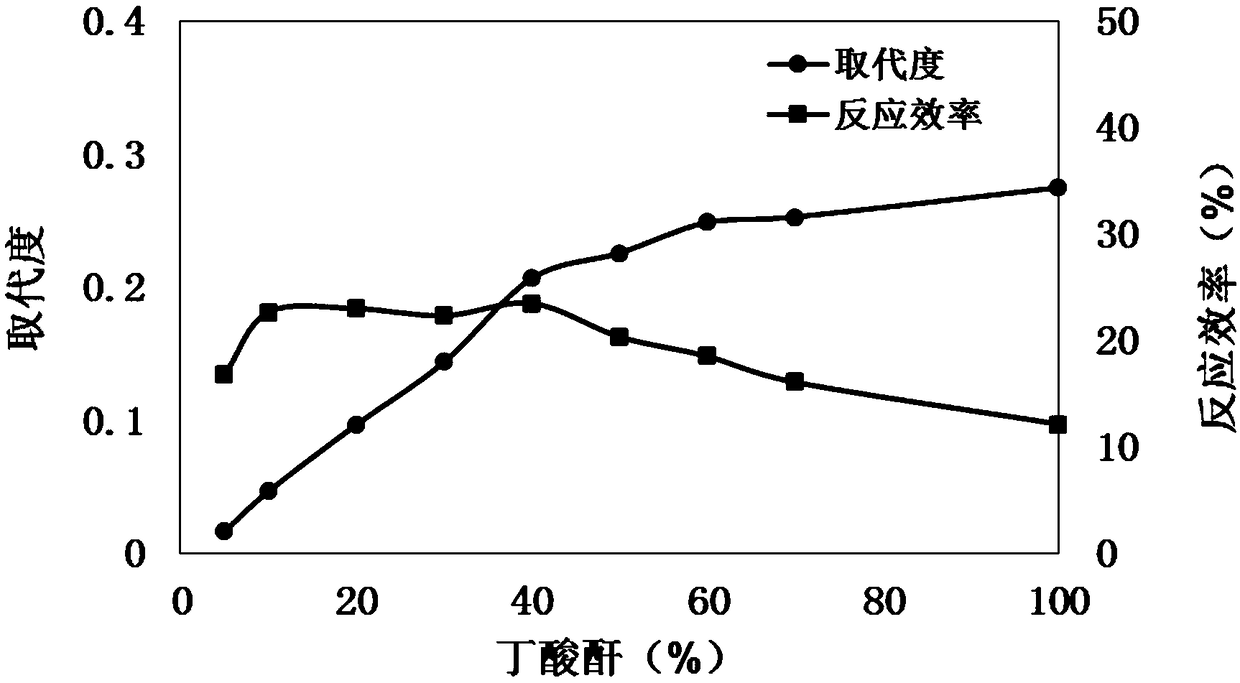

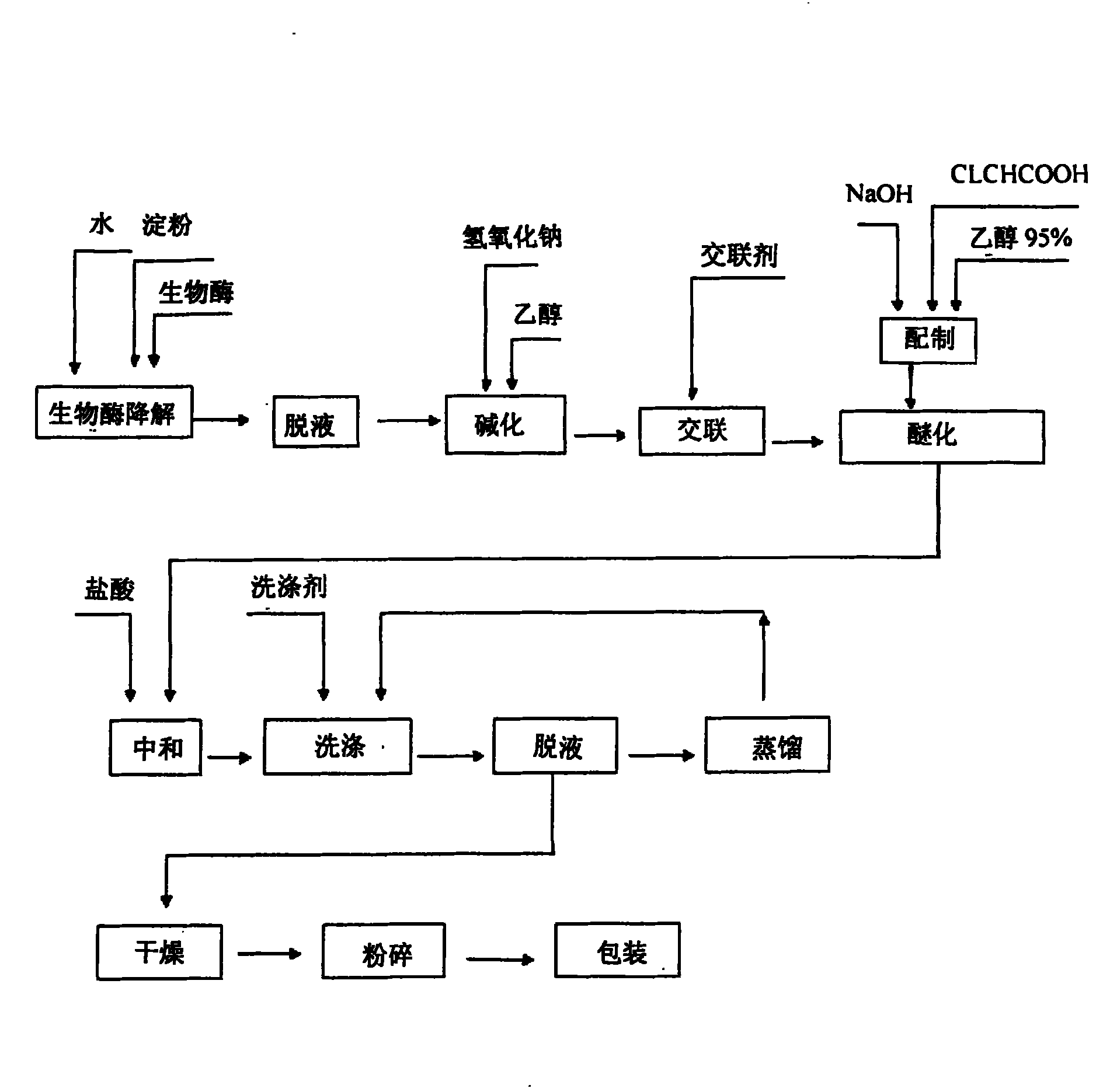

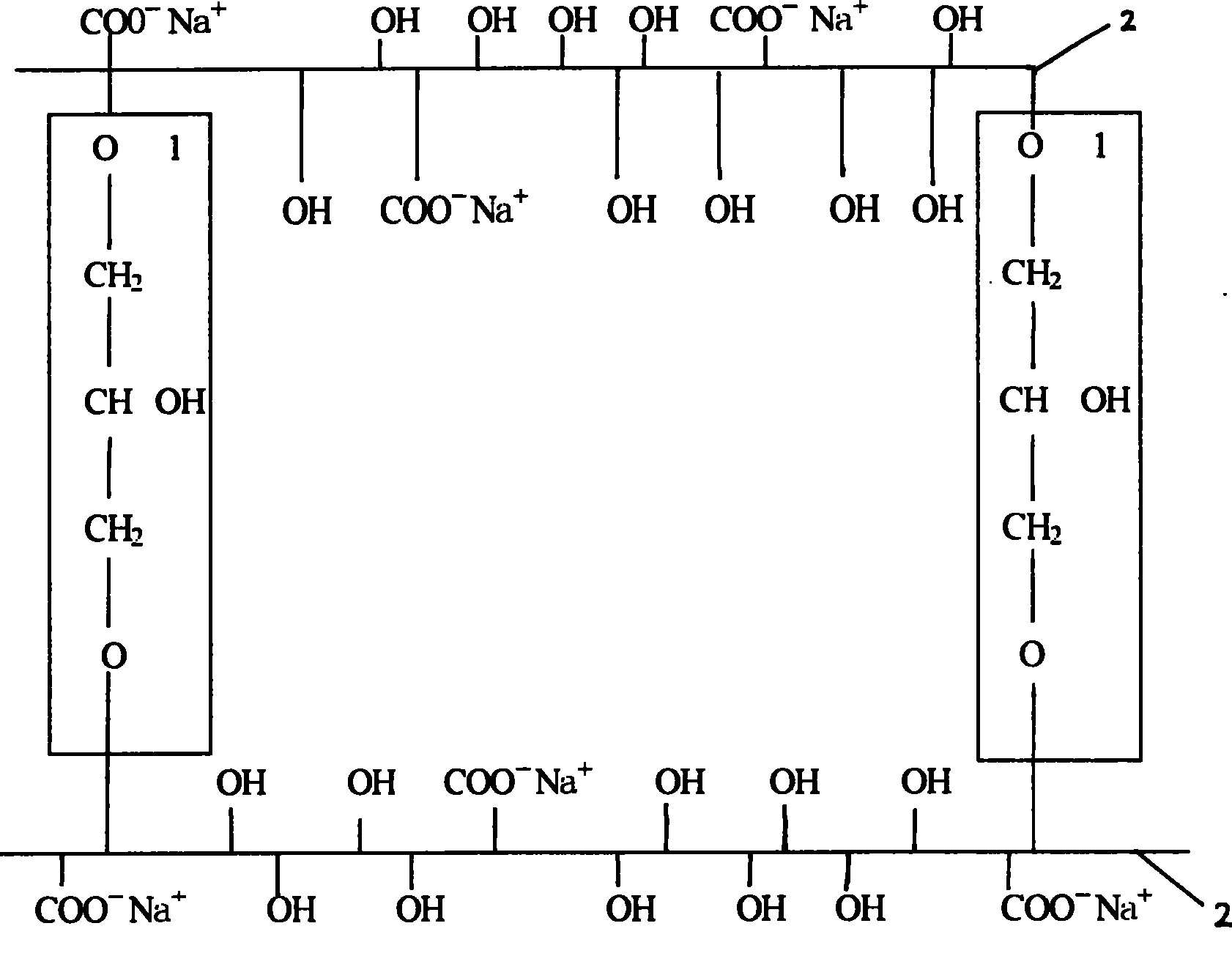

Preparation of medicinal disintegrating agent with biological enzymatic isolation method

InactiveCN101108251AImprove the uniformity of the reactionHigh reactivityPharmaceutical non-active ingredientsControlled releaseActive enzyme

The invention discloses a medical additives added into a medicine, in particular to a method to produce medicinal disintegration by biological enzymic method. The main technique is that: taking corn starch as the main material and ethanol as the dispersing agent. Making use of the selectivity of the biological enzyme Alpha-amylase to make the starch interrupt the chain structure under the effect of the biological active enzyme. By means of a plurality of compound degeneration ways such as alkalization, crosslinking and etherification, the starch is made into a new network structure and strong suction group. The invention has the advantages of the excellent efficacy, high absorbent, quick disintegration and controllable release, and can be widely used as releasing medicinal disintegration in tablets, capsules, controlled-release agent and granules.

Owner:SIPING DONGYI INNOVATION TECH

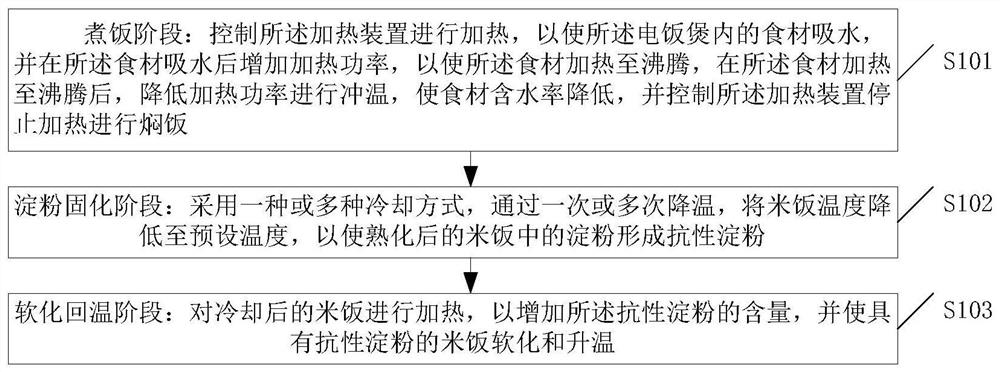

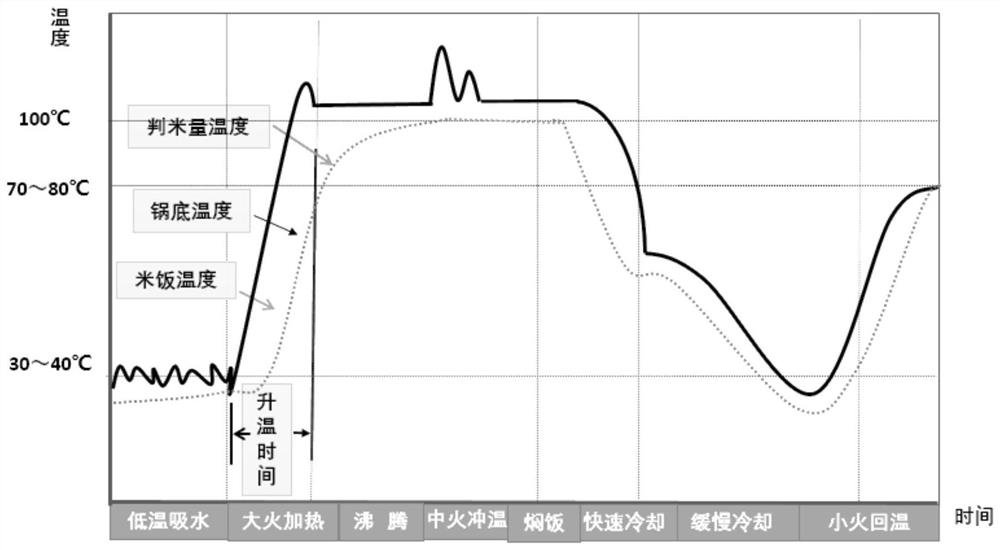

Rice cooking method of electric cooker

The embodiment of the invention discloses a rice cooking method of an electric rice cooker, which comprises the following steps: a cooking stage: controlling a heating device to heat to enable food materials in the electric rice cooker to absorb water, increasing the heating power after the food materials absorb water to heat the food materials to boil, and reducing the heating power to flush after the food materials are heated to boil to reduce the water content of the food materials, and stopping heating and braising the rice; a starch solidification stage: reducing the temperature of the cooked rice to a preset temperature by adopting one or more cooling modes through one or more times of cooling, so as to enable starch in the cooked rice to form resistant starch; and a softening and warming stage: heating the cooled rice to increase the content of the resistant starch, and softening and warming the rice with the resistant starch. Through the scheme of the embodiment, the content ofresistant starch in common rice is increased, so that the rising rate of postprandial blood sugar of a human body is reduced, and the nutrition and taste of the rice are guaranteed.

Owner:JOYOUNG CO LTD

Extruded Gelling Food Products, Extruded Gelling Food Product Ingredients, and Methods for Making Extruded Gelling Food Products and Extruded Food Product Ingredients

PendingUS20210337851A1Reduce the amount of solutionImprove digestibilityEdible oils/fats ingredientsDough treatmentBiotechnologyCarrageenan

The present invention is directed to an extruded food product constituent composed of a gelling food product constituent extrudate and method of extruding a gelling food product constituent extrudate used as an ingredient of a food product normally using a gelling gum, like guar gum, xanthan gum or carrageenan as an ingredient. The gelling food product extrudate is composed of cold-water soluble gelling pregelatinized starch formed of starch in a starch-containing admixture modified by extrusion at extrusion pressures greater than 2000 PSI that gels when mixed with water, which preferably also modifies additional starch or starches in the admixture into a plurality of different molecular weight polymers of a cold-water soluble gellant that polymerize forming a gel when mixed with water, preferably forming a hydrocolloid gel, which more preferably is a self-gelling gel, which even more preferably is a thermo-reversible gel crosslinked by one or more proteins freed by or modified during extrusion. Preferred admixtures configured to produce gelling extrudates include admixtures composed of cereal grains, including sorghum, wheat, oats, barley and / or corn, and / or legumes, including chick pea, yellow pea, pea and / or lentils with legume containing admixtures producing gelling extrudates that form thicker gels whose viscosity increases over time that are well suited for use in non-dairy dairy substitutes like non-dairy butter, non-dairy creamers, non-dairy whipped cream, non-dairy yogurt, non-dairy cream cheese, non-dairy cheese, and non-dairy ice cream.

Owner:GHL SPECIALTY FLOURS LLC

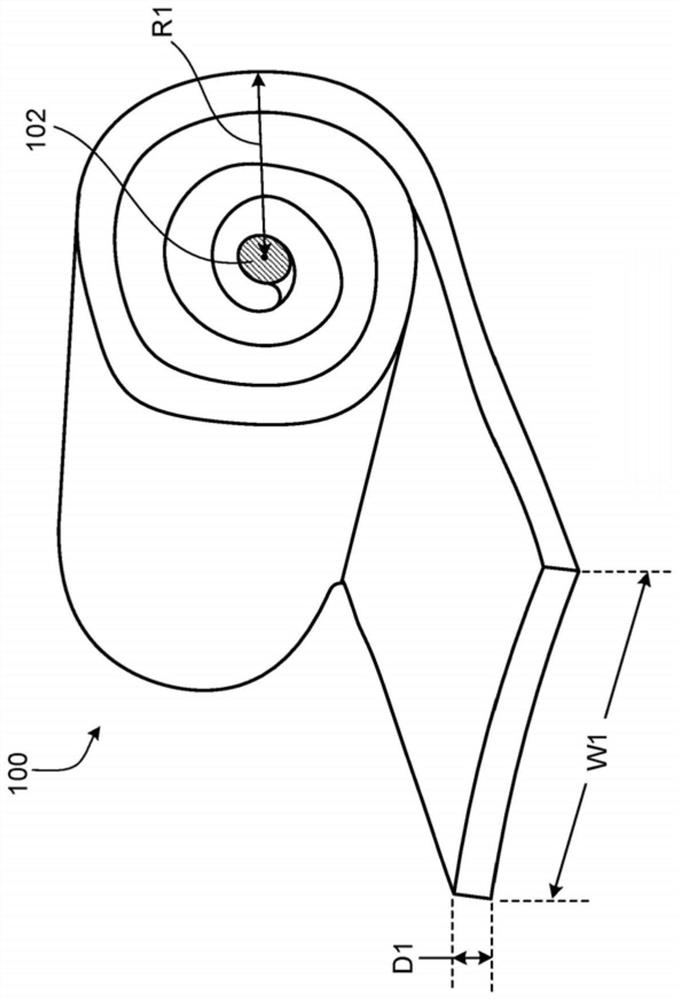

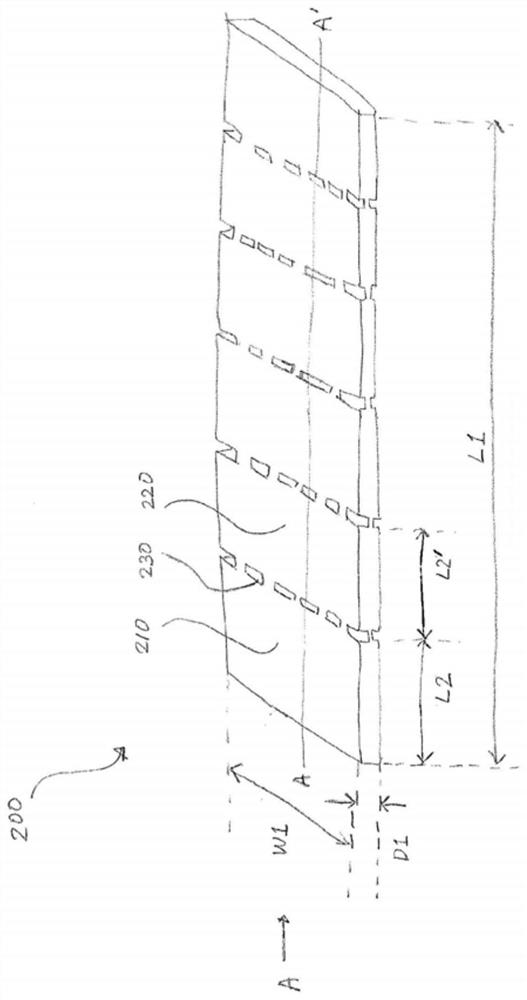

Compostable or recyclable packaging wrap

A compostable packaging wrap comprising: a strip that is primarily formed of starch and that is flexible such that the strip can be rolled is disclosed. In addition, a compostable or recyclable packaging wrap that includes: a first film that is primarily formed of one or more compostable or recyclable materials; a second film that is primarily formed of one or more compostable or recyclable materials; a plurality of pads, each pad being are surrounded by the first film and the second film and being primarily formed of one or more compostable or recyclable materials is disclosed. The compostable or recyclable packaging wrap is flexible such that the packaging wrap can be rolled.

Owner:VERICOOL INC

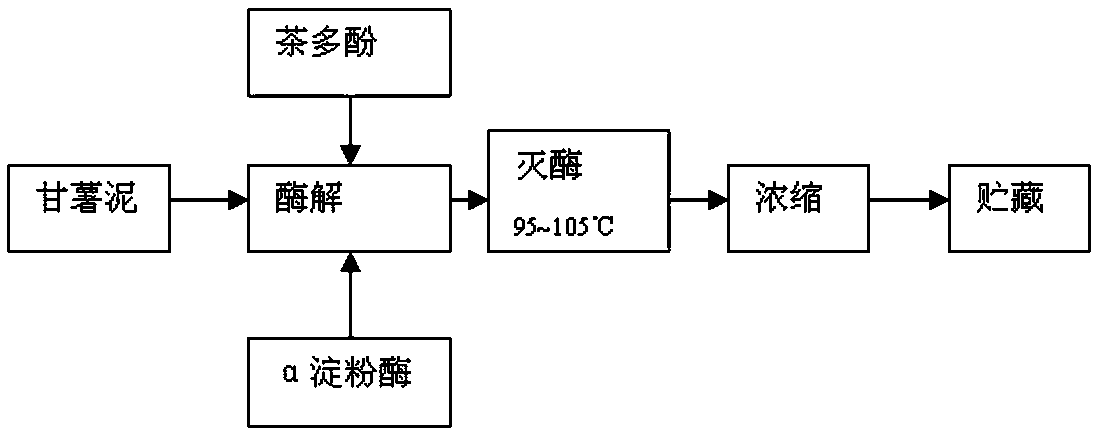

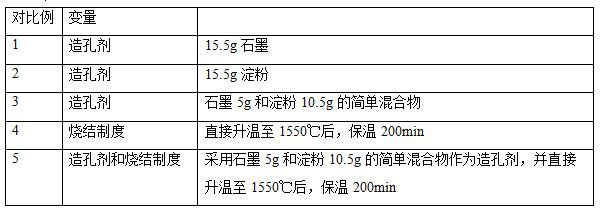

Mashed sweet potatoes capable of resisting ageing as well as making method and application of mashed sweet potatoes

InactiveCN108094973APrevent agingReduce in quantityDough treatmentFood ingredientsPotato starchChain length

The invention provides mashed sweet potatoes capable of resisting ageing as well as a making method and application of the mashed sweet potatoes. The mashed sweet potatoes capable of resisting ageingcomprise the following raw materials of mashed sweet potatoes, alpha-amylases and tea polyphenols. The method comprises the following steps of during preparation of the mashed sweet potatoes capable of resisting ageing, firstly, adopting the alpha-amylases, performing enzymolysis treatment on crude products of the mashed sweet potatoes under the appropriate condition for performing enzymolysis onstarch to a certain extent, changing the chain length, and strengthening the arrangement randomness of molecular chains to delay resuscitation. The mashed sweet potatoes have favorable application effect. The tea polyphenols are added, so that the condition that sweet potato starch forms a crystalline structure can be restrained, the course of crystallization can be delayed, the hardness of sweetpotato starch colloid is reduced, and the hardness and the color change of the colloid are reduced. The mashed sweet potatoes capable of resisting ageing are used for preparing various sweet potato products, and can effectively solve the problem of ageing of sweet potato products.

Owner:北京红螺食品有限公司

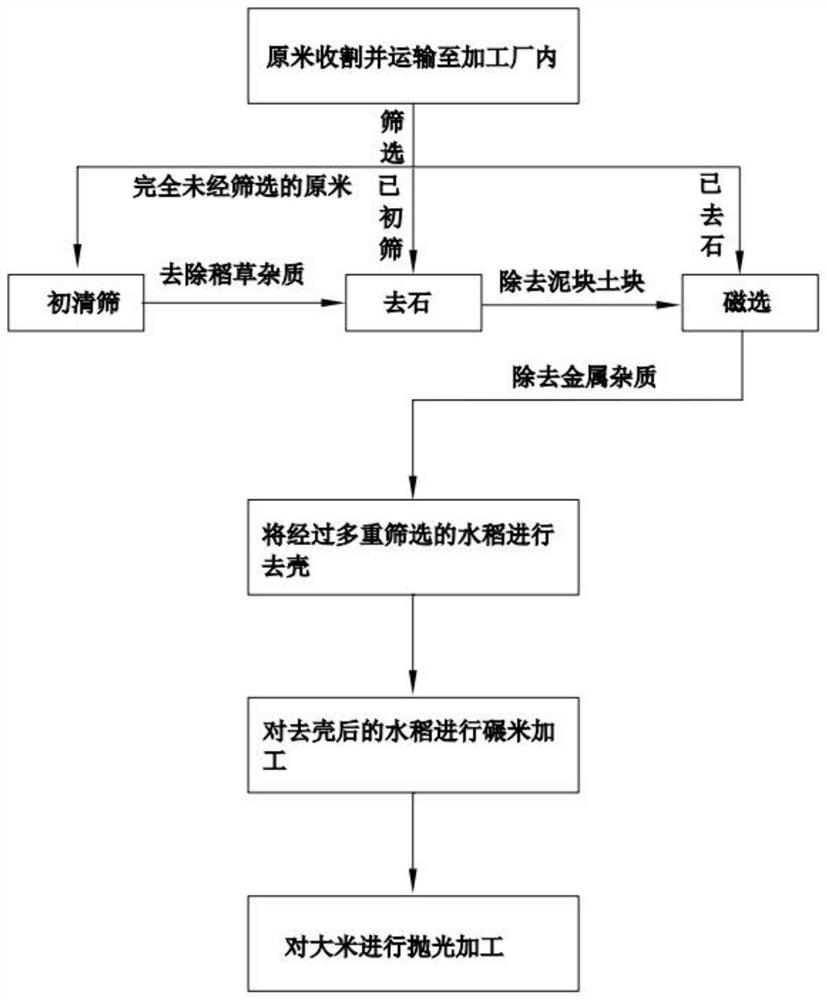

Finely selected rice processing technology

InactiveCN113145203ANice appearanceImprove bindingGrain huskingGrain polishingMetallurgyStarch formation

The invention provides a finely selected rice processing technology. The finely selected rice processing technology comprises the following steps of winnowing impurity removal, hot air drying, secondary winnowing, magnetic separation cleaning, rice hulling and shelling, husked rice separation, multi-stage fine grinding, rice polishing, screening color sorting and graded packaging. Compared with an existing rice processing technology, a nanometer water ion generator is arranged in a polishing machine in the polishing step, nanometer water ions can be generated through the nanometer water ion generator, starch on the surfaces of rice grains can be better and faster combined to form a gelatinous layer, the rice appearance is improved, the polishing time is shortened, and the possibility of rice nutrition loss and rice grain breaking caused by polishing is reduced; and the shot blasting with a silver ion plating layer is arranged, the release speed of silver ions can be increased in cooperation with the strong oxidizing property of nano water ions generated by the nano water ion generator, the rice is sterilized and disinfected in the polishing process, the subsequent sterilization and disinfection step is omitted, and good development prospects are realized.

Owner:陈忆君

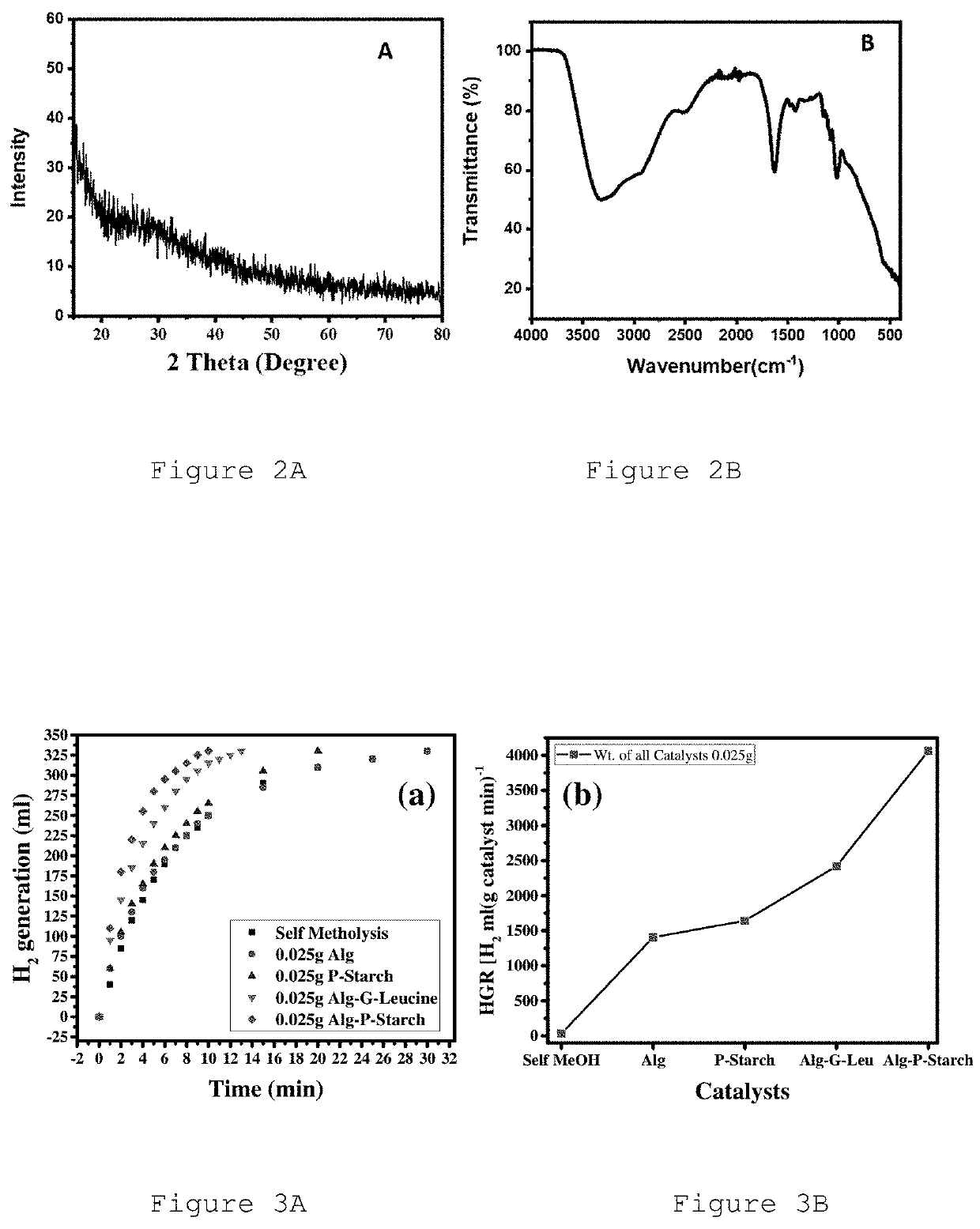

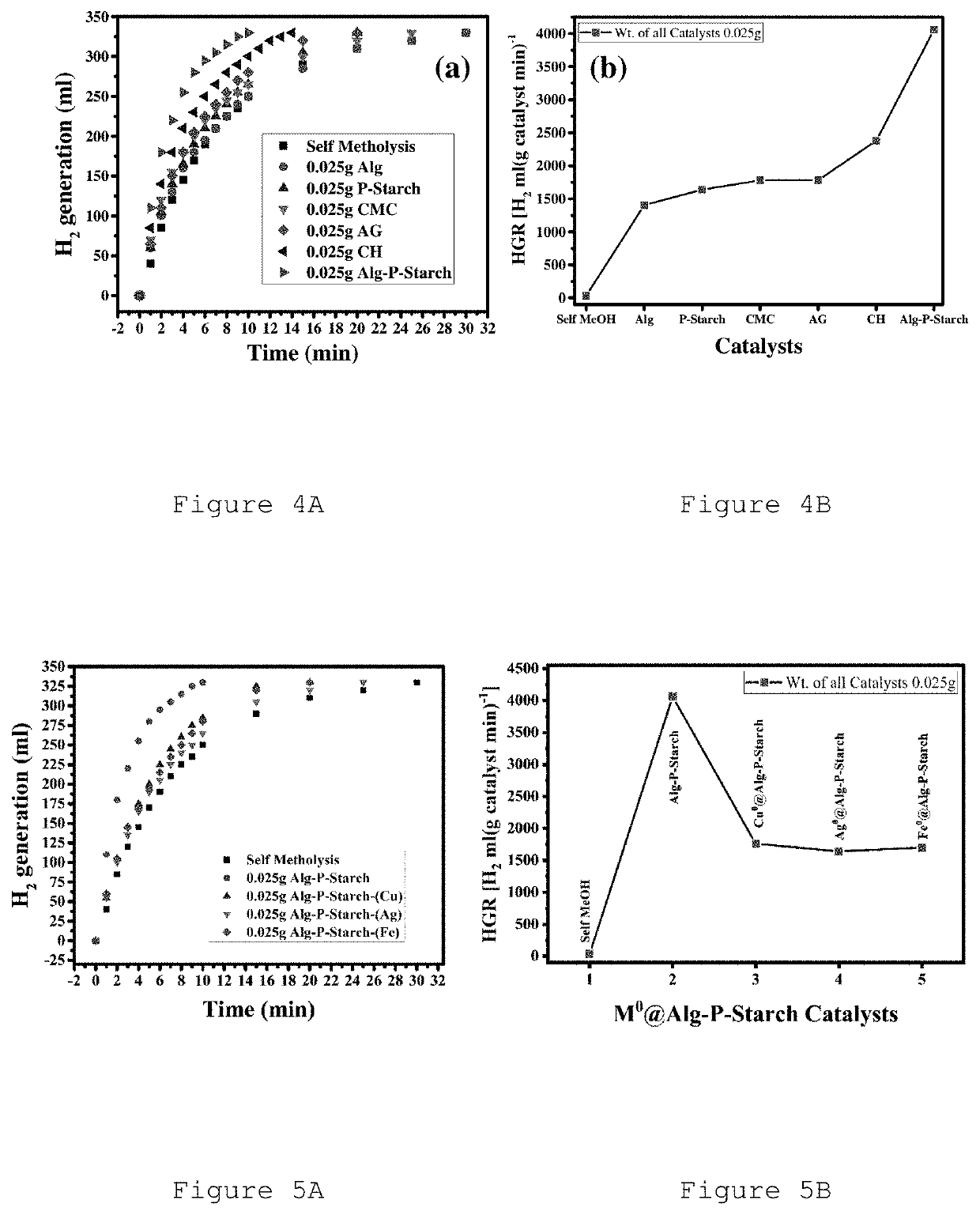

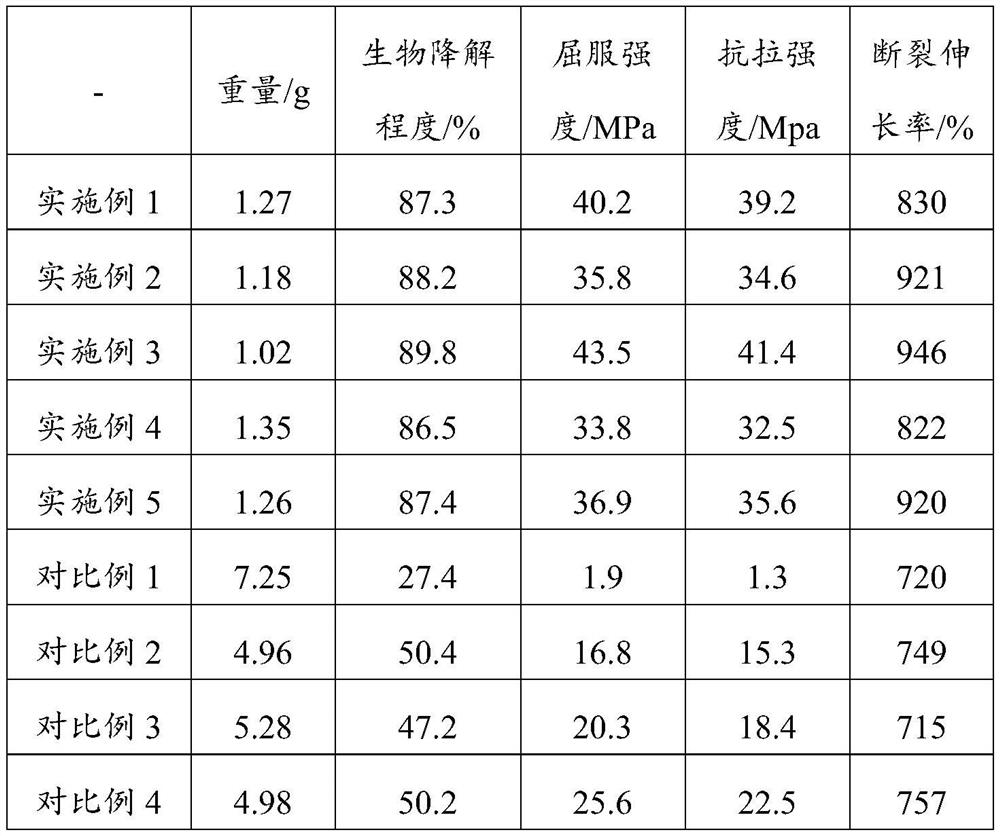

Efficient catalysts for hydrogen production

ActiveUS11433381B1Improve impact performanceFast and high quantity of hydrogen productionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystActive agent

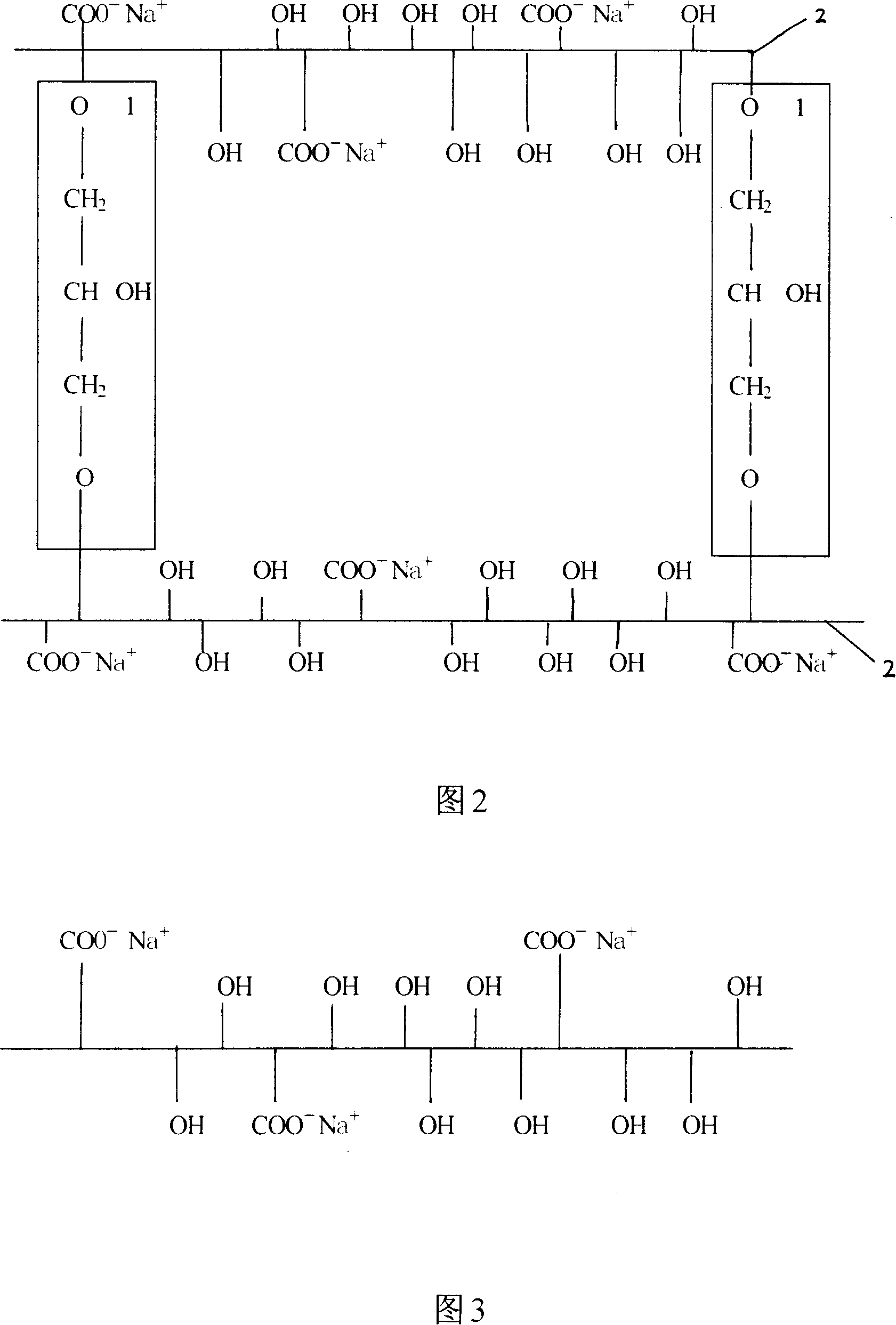

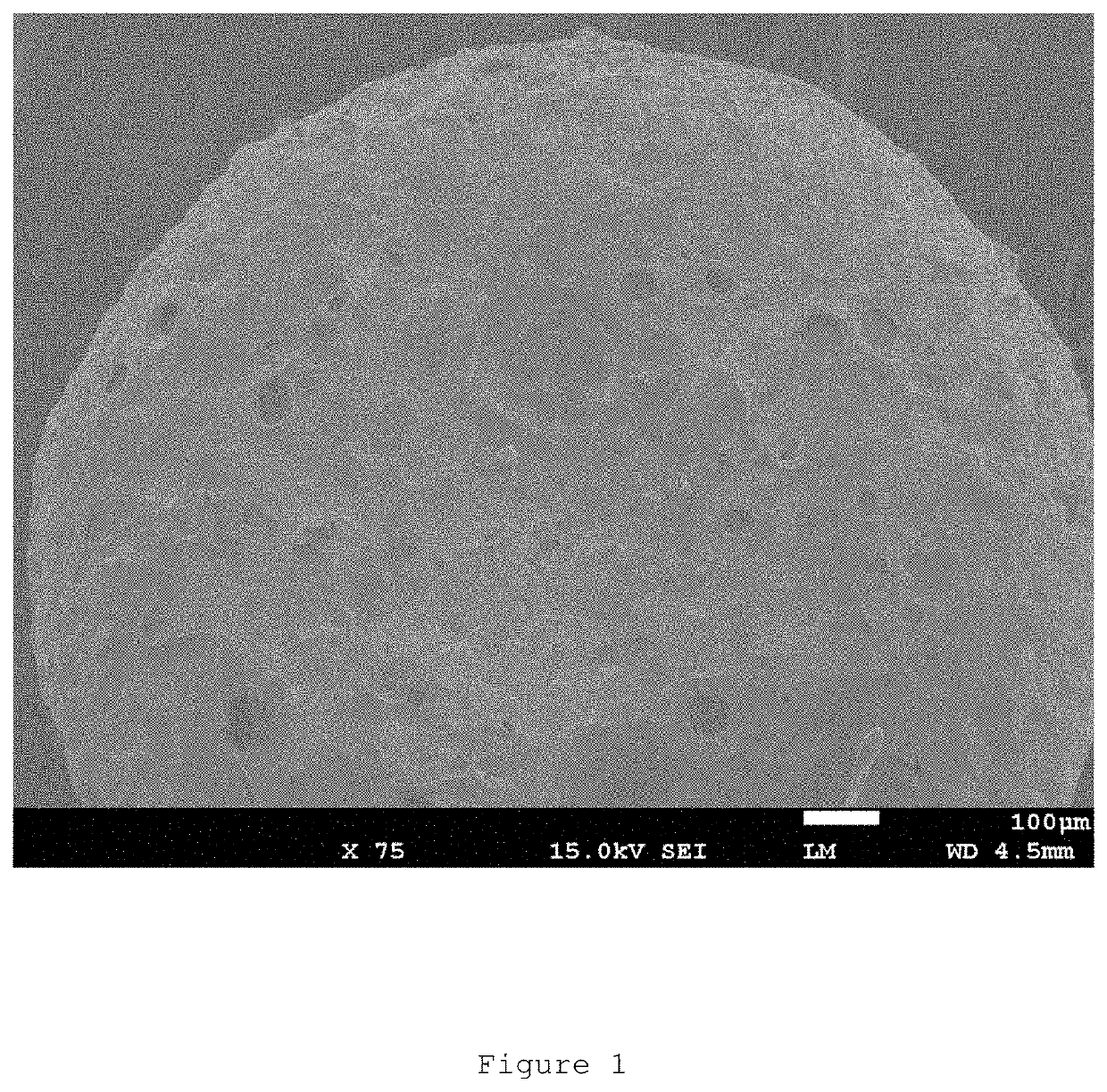

Catalysts for hydrogen production from NaBH4 by hydrolysis or alcoholysis are provided. The catalysts comprise hydrogel beads formed from alginate and starch. The hydrogel beads optionally comprise metal nanoparticles on their surfaces, and the hydrogen generation reactions are optionally conducted in the presence of one or more surfactants.

Owner:KING ABDULAZIZ UNIV

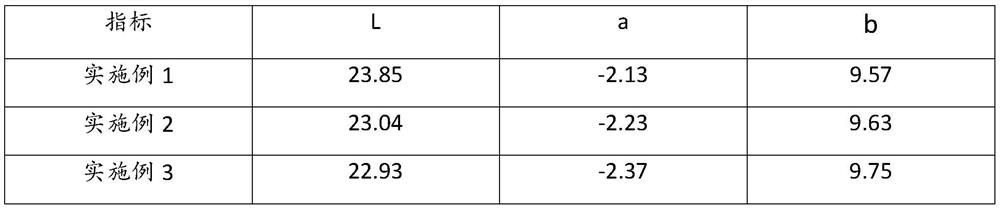

Starch-based elastomer as well as preparation method and application thereof

The invention discloses a starch-based elastomer as well as a preparation method and application thereof. The starch-based elastomer is prepared from the following raw materials: polypropylene carbonate polyol, polycaprolactone glycol, modified starch, straw, filler and an auxiliary agent, wherein the modified starch is iron ion modified starch. According to the invention, ferric ions and starch form a complex, and a coordination cluster formed by a coordination reaction has a physical cross-linking effect, can limit the movement of a starch molecular chain, improve the shear viscosity of a melt, play an anti-plasticizing effect and prolong the extrusion retention time of the melt, so that the shear degradation effect of a screw is improved to a certain extent, and the mechanical property of the screw is improved. The strength and the thermal stability of the starch are improved. The elastomer prepared from the modified starch has good mechanical properties and degradability.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

A kind of peppermint sandwich chip and preparation method thereof

ActiveCN111374336BUnbreakableStrong aroma and good tasteFood coatingFood shapingMentha spicataPulp and paper industry

The mint sandwich chip and the preparation method thereof provided by the present invention are as follows: mint leaves are beaten into mint pulp, and starch is added to form a batter to improve the viscosity of the mint pulp and make it easier to form; the batter is placed in a mold, and Sprinkle fine material, the addition of fine material makes it not easy to break during the first baking process, and at the same time enhances the taste of prefabricated crisps and mint sandwich crisps; spread coarse material between two prefabricated crisps to form a sandwich structure, The strength of the prefabricated crisps is increased, so that the mint-filled crisps obtained after the second baking are not only rich in fragrance and good in taste, but also not easy to break.

Owner:KUNMING UNIV OF SCI & TECH

Processing method of instant sweet potato rice noodles

InactiveCN106107688ARich in proteinRich in vitaminsClimate change adaptationFood hydrolysisCelluloseFlavor

A processing method of instant sweet potato rice noodles comprises the following steps: initial treatment of sweet potato; cleaning treatment of the sweet potato; treatment of sweet potato peel; pulverization treatment of sweet potato fresh; blending and starch formation of sweet potato powder; manufacturing of rice noodles; and treatment of the rice noodles. The sweet potato powder is adopted as a main raw material; after the sweet potato is buried into soil and dried, the tenacity of cellulose can be kept, and starch and certain glucoside can be fully retained; sweet potato peel juice subjected to enzymolysis is utilized as blending liquid, so that the rice noodles contain abundant pectin, protein and vitamins, and the manufactured rice noodles are good in elasticity; the rice noodles cannot deform and bind together under the effect of squeeze; the rice noodles are not liable to breakage after being cooked; and the flavor of the rice noodles is fresh and sweet, and the rice noodles taste delicious.

Owner:ANHUI SANXIONGDI POTATO IND

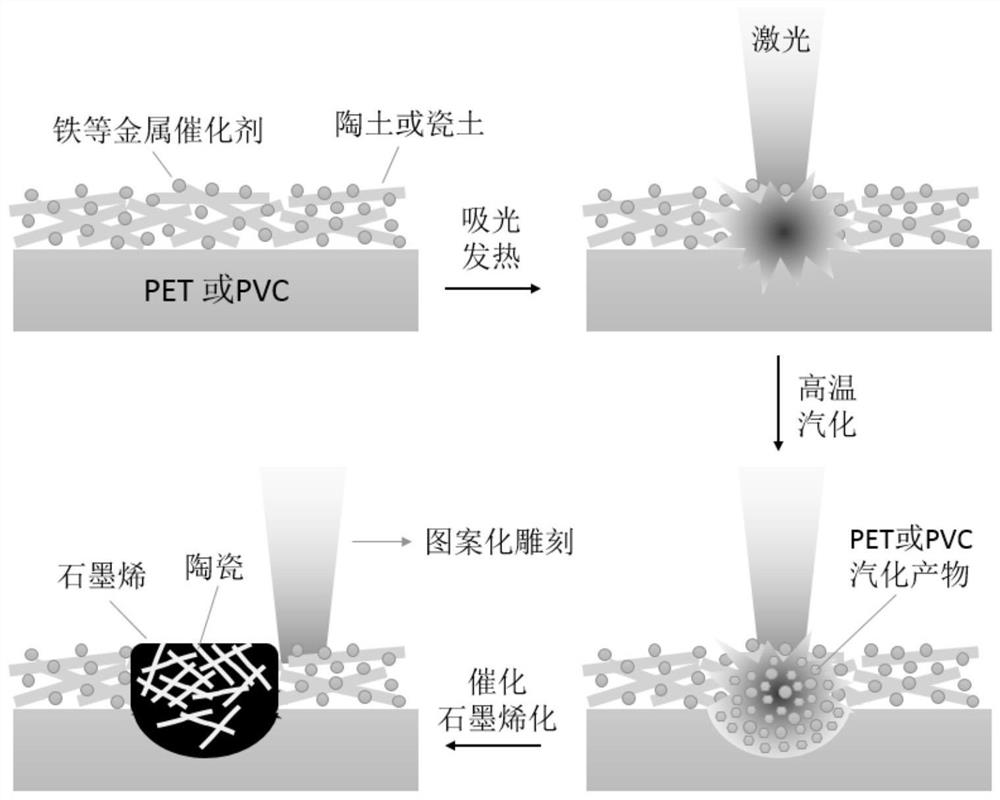

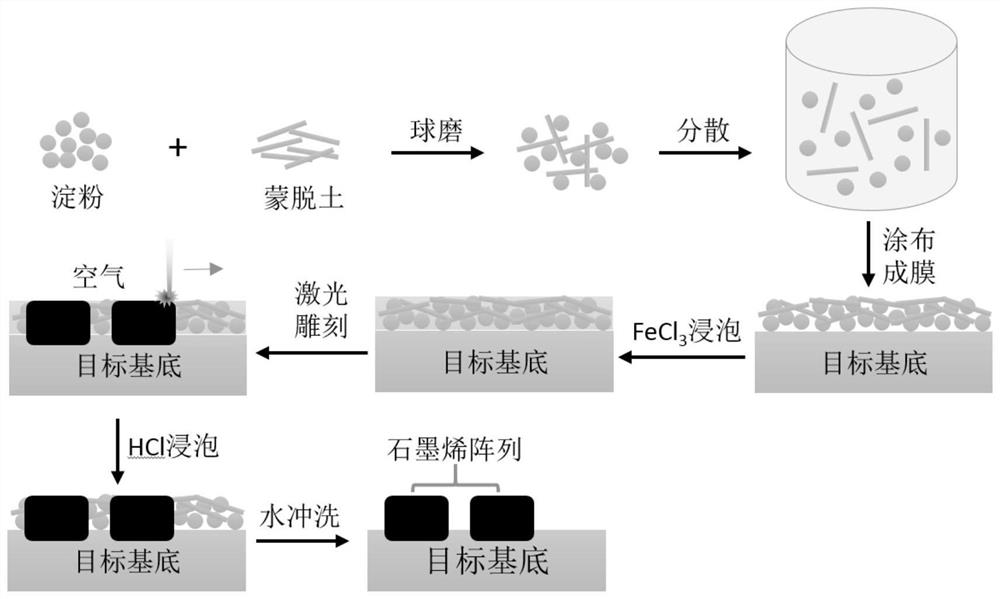

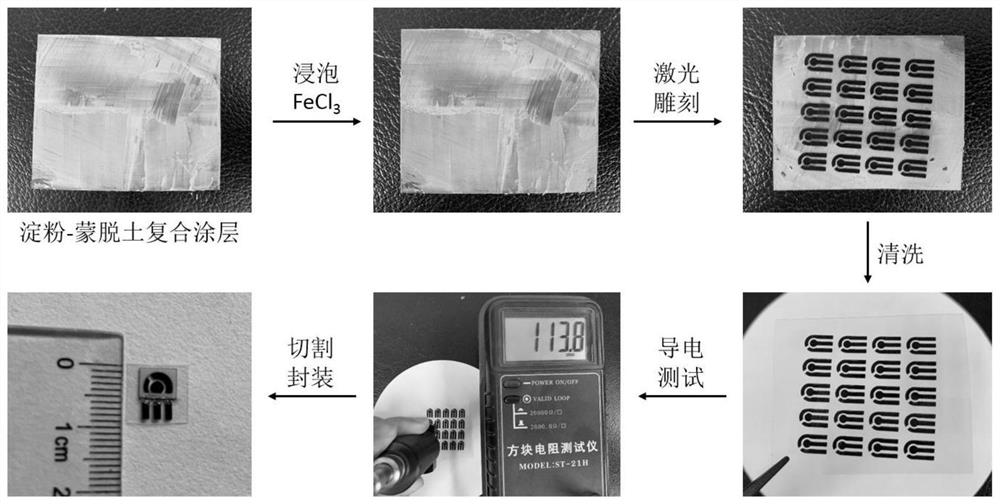

Laser engraving preparation method and application of graphene-ceramic composite electrode array

ActiveCN112723855BImprove mechanical propertiesImprove conductivityClaywaresCeramic compositePtru catalyst

The invention belongs to the field of materials, and relates to a laser engraving preparation method of a graphene-ceramic composite electrode array and an application thereof. The laser engraving preparation method of the graphene-ceramic composite electrode array, the ceramic raw material is mixed alone or with starch and added with water to form a paste slurry, and then coated on the surface of the plastic substrate to form a coating, dried, and then laser engraved on the coating , to prepare graphene-ceramic composite electrode arrays. In the preparation method of the present invention, the coating formed by the ceramic raw material alone or with starch can absorb light to generate instantaneous high temperature during the laser engraving process, and vaporize the plastic substrate at the bottom of the coating, and after the vaporization products of these plastic substrates enter the coating, they can be The metal catalyst in the ceramic raw material is carbonized to form graphene, and the ceramic raw material itself is transformed into a ceramic under high temperature, so that a graphene-ceramic composite electrode array with certain mechanical strength and hydrophilicity is formed in situ.

Owner:WUHAN UNIV

Regulating agent for promoting flood-resistant growth of direct-seeding rice and use method of regulating agent

PendingCN114586790AInhibits bulk swellingImprove permeabilityBiocideSeed and root treatmentCelluloseSodium starch

The invention belongs to the technical field of rice planting, and particularly relates to a regulating agent for promoting flood-resistant growth of direct seeding rice and a using method thereof.The growth regulating agent is prepared from, by weight, hydroxy propyl cellulose, sodium alginate, starch, gibberellin, hydroxymethyl chitosan, inorganic salt, a bactericide, an insecticide, an oxygen producer and water; the use method comprises the following steps: mixing gibberellin, hydroxymethyl chitosan, inorganic salt, bactericide and insecticide to form a mixture A; mixing hydroxy propyl cellulose, sodium alginate and starch to form a mixture B, and then adding the mixture A to obtain the growth regulating agent; before sowing, direct sowing rice seeds are completely soaked in a growth regulating agent solution. Hydroxyl forms hydrogen bonds to form a mixed film with good performance, the slow release function is improved, the permeability of the film is improved, then rice seeds can be prevented from being in a long-term waterflooding state, rice growth is promoted, the stress resistance of crops is improved, and the product yield can be increased.

Owner:YIBIN UNIV +1

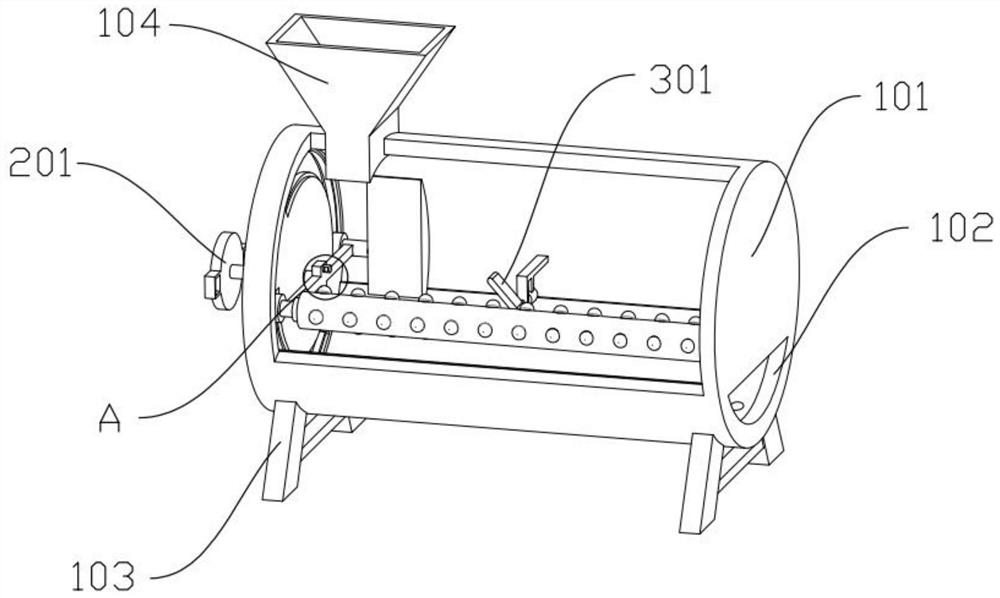

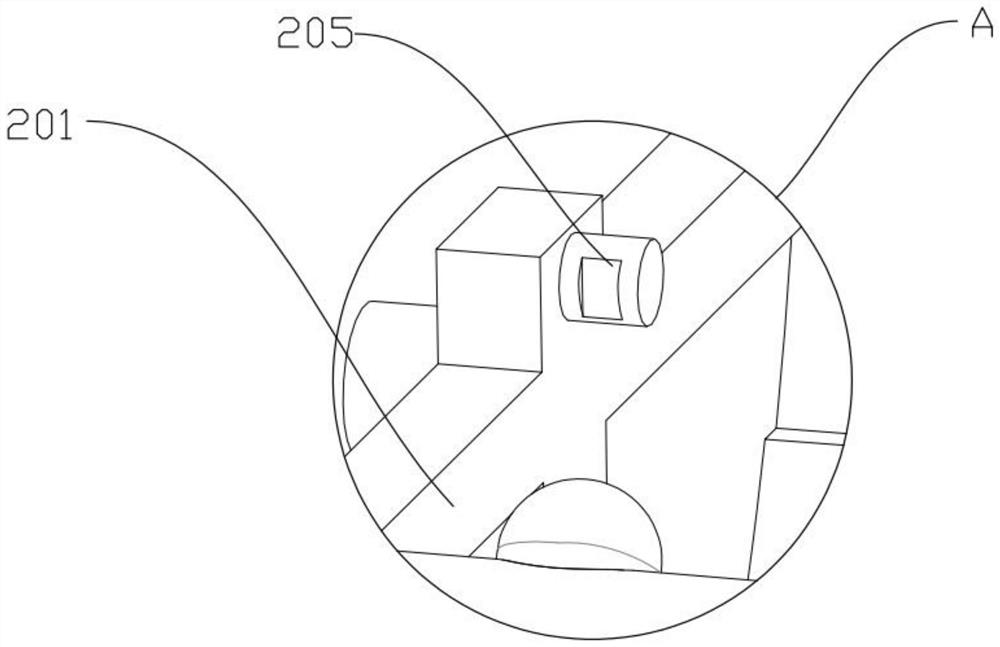

Rice processing technology

The invention relates to the field of rice processing, in particular to a rice processing technology. A screen mesh can be cleaned and the processing efficiency can be improved without using a tool on the outer side of a device or stopping feeding when the screen mesh is blocked. The rice processing technology comprises the following steps that step 1, harvested raw rice is added into a screening device to filter rice straw; step 2, multiple screening is carried out on the raw rice subjected to straw filtering again to remove impurities; step 3, the rice subjected to impurity removal is hulled; step 4, the hulled rice is subjected to roughening and whitening; and step 5, the milled rice is polished, so that starch on the surface of the rice forms a gelatinous layer, the shelf life is prolonged, and a screening device in the first step comprises a screening barrel, filtering holes, a slope bottom plate, a connecting plate and a feeding arc plate.

Owner:湖南湘科米业股份有限公司

Preparation of medicinal disintegrating agent with biological enzymatic isolation method

InactiveCN101108251BImprove the uniformity of the reactionHigh reactivityPharmaceutical non-active ingredientsAmylaseActive enzyme

The invention discloses a medical additives added into a medicine, in particular to a method to produce medicinal disintegration by biological enzymic method. The main technique is that: taking corn starch as the main material and ethanol as the dispersing agent. Making use of the selectivity of the biological enzyme Alpha-amylase to make the starch interrupt the chain structure under the effect of the biological active enzyme. By means of a plurality of compound degeneration ways such as alkalization, crosslinking and etherification, the starch is made into a new network structure and strongsuction group. The invention has the advantages of the excellent efficacy, high absorbent, quick disintegration and controllable release, and can be widely used as releasing medicinal disintegration in tablets, capsules, controlled-release agent and granules.

Owner:SIPING DONGYI INNOVATION TECH

A kind of method for preparing butyrate starch

ActiveCN109400725BPrevent volatilizationGood resistance to enzymatic hydrolysisFood ingredient functionsBiotechnologyButyric anhydride

The invention discloses a butyrate starch preparing method and belongs to the technical fields of preparation and application of modified starch and deep processing of agricultural products. Accordingto the butyrate starch preparing method, starch serve as the principal raw material for esterification with butyric anhydride to achieve stabilization of butyric acid and small releasing of the butyric acid in gastric juice; resistant starch prepared through esterification of the butyric acid and the starch can well avoid being absorbed in small intestines, resist digestion by enzymes secreted bybrush borders, selectively release micromolecular effective load in large intestines; fermented by enteric microorganisms, the resistant starch can produce more short-chain fatty acids and probiotics, thereby improving the bioavailability of the butyric acid and expanding the application range of the starch. Compared with other butyric acid products, the butyrate starch is odorless and can be esterified into the resistant starch to convey the butyric acid to the rear end of the intestines; the butyrate starch can be fermented by the enteric microorganisms and decomposed by bacterial esteraseinto butyric acid and other short-chain fatty acids and increase the content of the probiotics, thereby belonging to probiotic products.

Owner:JIANGNAN UNIV

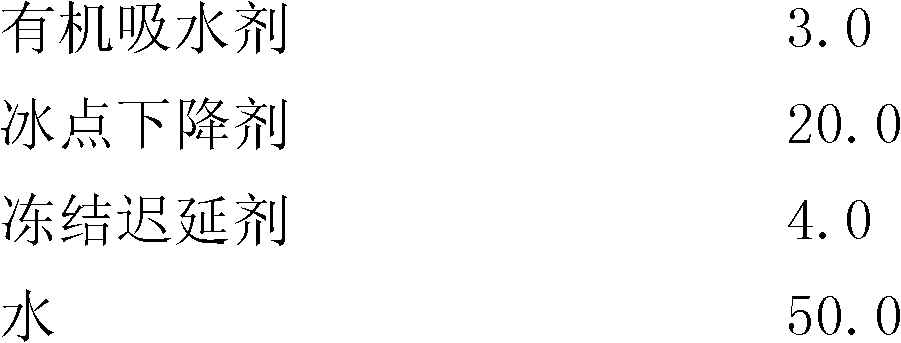

Antifreezing snow melting agent and preparation method thereof

Owner:DALIAN POLYTECHNIC UNIVERSITY

High-voltage-resistant solid aluminum electrolytic capacitor and preparation method thereof

ActiveCN113674998AImprove pressure resistanceCapacitor electrolytes/absorbentsCapacitor electrodesAluminium electrolysisConductive polymer

A high-voltage-resistant solid aluminum electrolytic capacitor comprises a shell, a core package and a rubber plug; the core package is arranged in the shell in a sealed mode through the rubber plug; the core package is formed by winding an anode foil, electrolytic paper and a cathode foil, a polymer conductive gel film is formed between the anode foil and the cathode foil, and the polymer conductive gel film comprises gel formed by starch; and the weight of the starch accounts for 20-50% of the weight of the high-molecular conductive polymer. According to the invention, a certain amount of starch is added into a dispersion liquid, the starch and PEDOT: PSS are dried together to form a layer of polymer conductive gel between the anode foil and the cathode foil, and under the effect of the gel, even if leakage current exists on the surface of the anode foil, the voltage withstanding value of the polymer conductive gel is increased, and further, the withstand voltage value of the solid aluminum electrolytic capacitor is improved.

Owner:YIYANG WANJINGYUAN ELECTRONICS

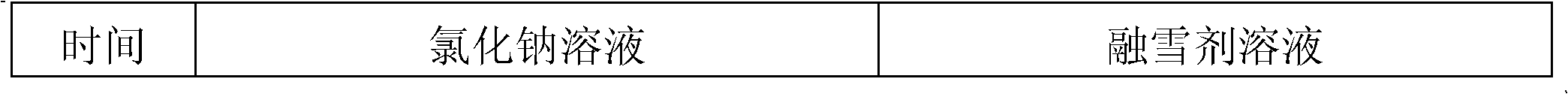

a kind of al 2 o 3 Preparation method and application of porous ceramics

ActiveCN112939585BSimple processReduce manufacturing costCigar manufactureCeramicwareStarch formationPorous ceramics

The invention relates to the technical field of tobacco carriers, in particular to an Al 2 o 3 Preparation methods and applications of porous ceramics. It uses magnesium raw material, aluminum raw material, and pore-forming agent as raw materials, and sequentially includes steps of mixing, molding, drying, and sintering; the pore-forming agent includes inorganic carbon coated with starch; in the sintering step, sequentially includes: a. To 220-300°C, keep warm for more than 30min; b. raise the temperature to above 1500°C, keep warm for more than 30min. In the present invention, the starch-coated inorganic carbon is used as a pore-forming agent. During the sintering process, starch is used to form pores at a low temperature, and the pores are supported by the inorganic carbon to prevent the pores from collapsing and closing, which can effectively increase the apparent porosity of the porous ceramics obtained by sintering.

Owner:HUBEI CHINA TOBACCO IND

Mint sandwich crisp chips and preparation method thereof

ActiveCN111374336AUnbreakableStrong aroma and good tasteFood coatingFood shapingMentha spicataEngineering

The present invention provides mint sandwich crisp chips and a preparation method thereof. Mint leaves are ground into mint pulp, and starch is added to form paste so as to improve the viscosity of the mint pulp and making the mint pulp easier to form; the paste is placed into a mold and fine materials are spread on the surface of the paste, so that the addition of the fine materials ensures thatthe paste is not easy to break in a first baking process, and the taste of prefabricated crisp chips and the mint sandwich crisp chips is enhanced; and coarse materials are spread between the two prefabricated crisp chips to form a sandwich structure, so that the strength of the prefabricated crisp chips is enhanced, and the mint sandwich crisp chips obtained after second baking not only are richin aroma and good in taste, but also are not easy to break.

Owner:KUNMING UNIV OF SCI & TECH

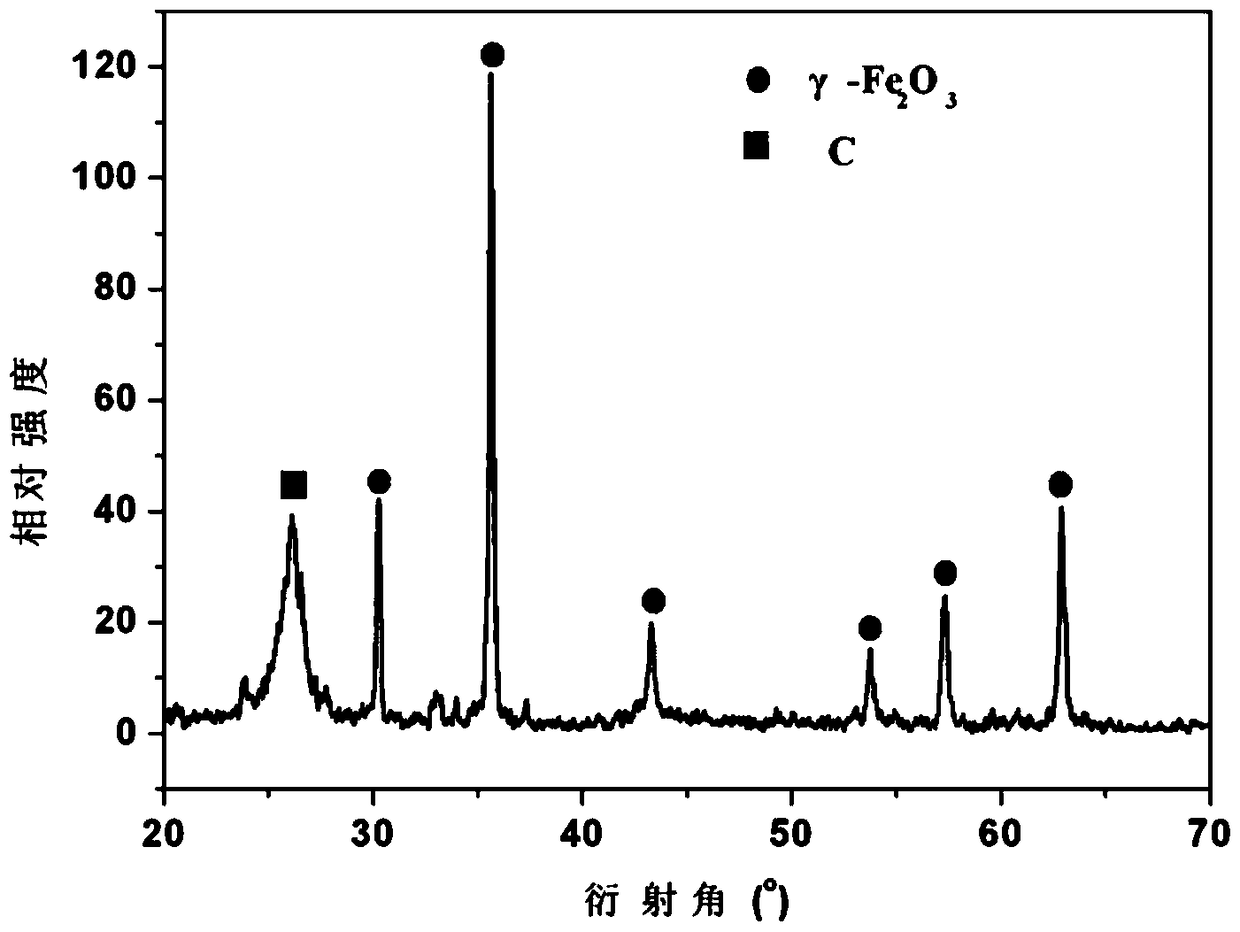

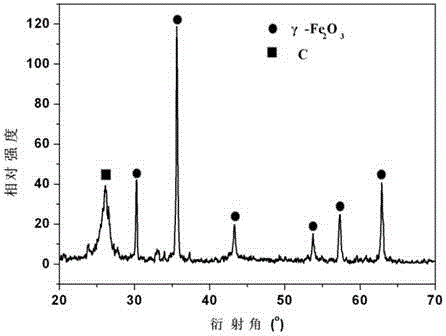

A method for preparing c/γ-fe2o3 composite material from acid-regenerated desiliconized mud cake

ActiveCN105435738BReduce pollutionSimple processFatty/oily/floating substances removal devicesOther chemical processesEngineeringSlurry

A method of preparing a C / gamma-Fe2O3 composite material from acid-regeneration desilication mud cakes is disclosed. The method includes a) adding water into block desilication mud cakes, pulping under heating, and adding furfuryl alcohol, furfural or starch the mass of which is 2-5 times of that of the desilication mud cakes so as to form desilication mud slurry with food dispersity, b) subjecting the slurry in the step a) to spray drying at 100-120 DEG C to obtain coated desilication mud powder, and c) adding the desilication mud powder obtained in the step b) into a heating furnace, raising the temperature to 600-900 DEG C at a heating speed of 2-5 DEG C / min under inert gas protection, maintaining the temperature for 4-8 h after reaching the target temperature, and cooling inside the furnace to obtain the C / gamma-Fe2O3 composite material. The method of preparing the C / gamma-Fe2O3 composite material from the acid-regeneration desilication mud cakes is provided. The starch, the furfuryl alcohol or the furfural which are cheap are utilized for coating, and then thermal cracking is performed to obtain the magnetic carbon material. The method effectively achieves recovery and reutilization of resources.

Owner:BAOSHAN IRON & STEEL CO LTD

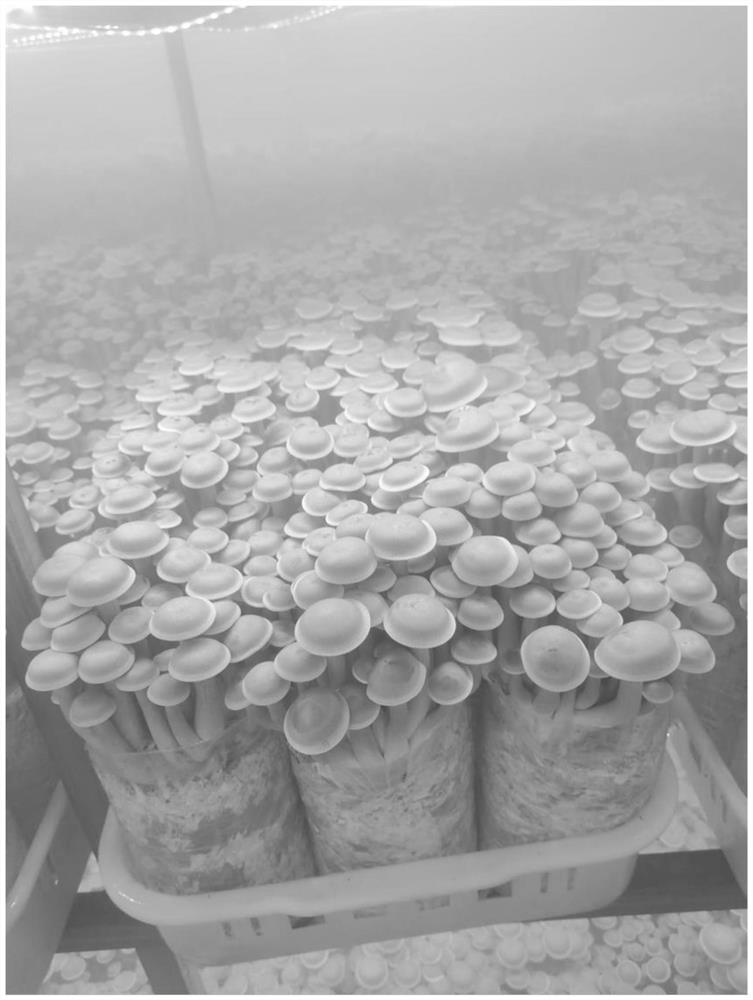

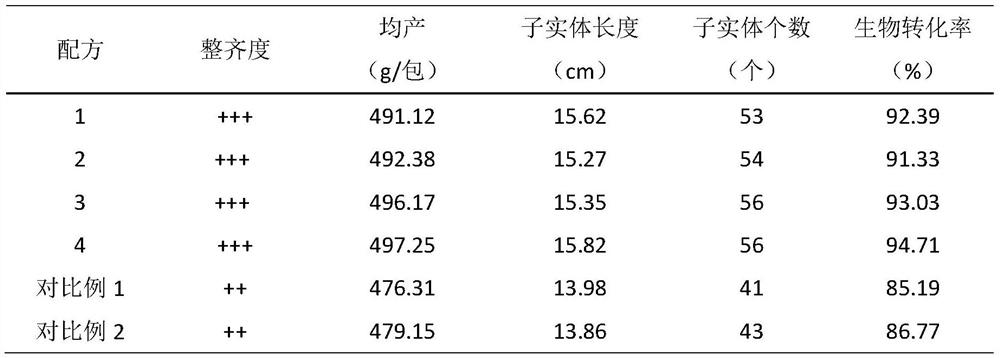

Lyophyllum decastes culture medium containing fir sawdust and preparation method of lyophyllum decastes culture medium

PendingCN113924921AFast natural degradationPromote accumulationCultivating equipmentsMushroom cultivationCelluloseStarch formation

The invention relates to the technical field of lyophyllum decastes culture, in particular to a lyophyllum decastes culture medium containing fir sawdust and a preparation method of the lyophyllum decastes culture medium. The lyophyllum decastes culture medium is prepared from the following raw materials in parts by weight: 1-3 parts of poplar wood chips, 2-3 parts of cedar wood chips, 2-4 parts of corncobs, 2-3 parts of wheat bran, 1-2 parts of cottonseed hulls, 1-2 parts of corn flour and 0.01-0.03 part of soluble sugar. The soluble sugar is extracted from Chinese yam and white gourd in a mass ratio of 1:(3-5). By using the poplar wood chips and the cedar wood chips and utilizing the characteristics of low cost and rich cellulose minerals, the prepared culture medium can be more easily absorbed by the lyophyllum decastes, and can form a good inclusion with soluble sugar and starch, so that the accumulation of nutrient substances of the lyophyllum decastes is promoted, the growth of the lyophyllum decastes is accelerated, the planted lyophyllum decastes grows faster, and higher uniformity and biotransformation rate are achieved.

Owner:贵州省贵福菌业发展有限公司

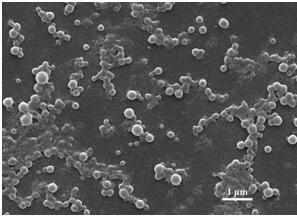

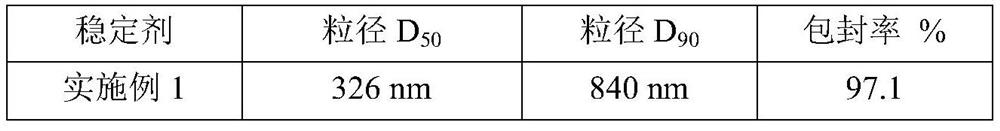

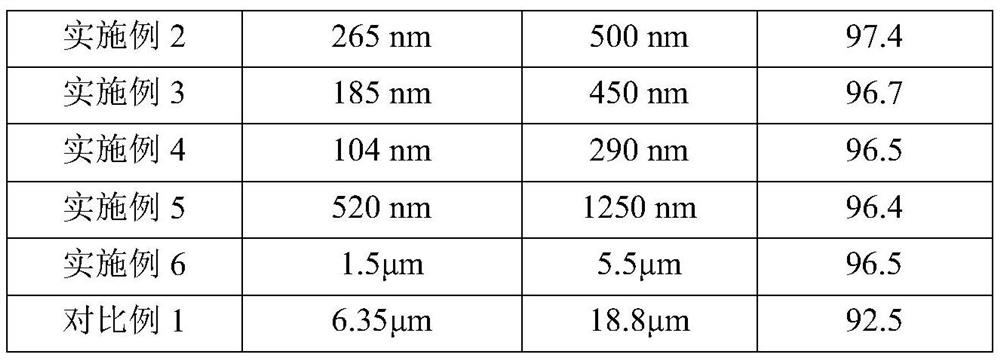

A kind of glycosylated pesticide nano-microcapsule and preparation method thereof

ActiveCN109526952BLarge particle sizeIncreased biodegradable propertiesBiocideFungicidesStarch formationPolyurea

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Fermentation culture medium for producing tetracycline by fermenting streptomyces aureus and feeding method

InactiveCN112760352AReduce consumptionInhibit synthesisMicroorganism based processesFermentationBiotechnologyStreptomyces auratus

The invention relates to a fermentation culture medium for producing tetracycline by fermenting streptomyces aureus and a feeding method. The fermentation culture medium and a feeding base material both adopt methyl esterified grease as an auxiliary carbon source. Methyl esterified grease is introduced and forms an auxiliary carbon source with starch, so that synthesis of fatty acid can be effectively prevented, a metabolic pathway of a product is enhanced, the fermentation level is improved, and the consumption of the starch is reduced.

Owner:NINGXIA QIYUAN PHARMA

Degradable mosquito net bag

PendingCN114369951AExtended service lifeImprove toughnessFlexible coversWrappersCopolyesterStarch formation

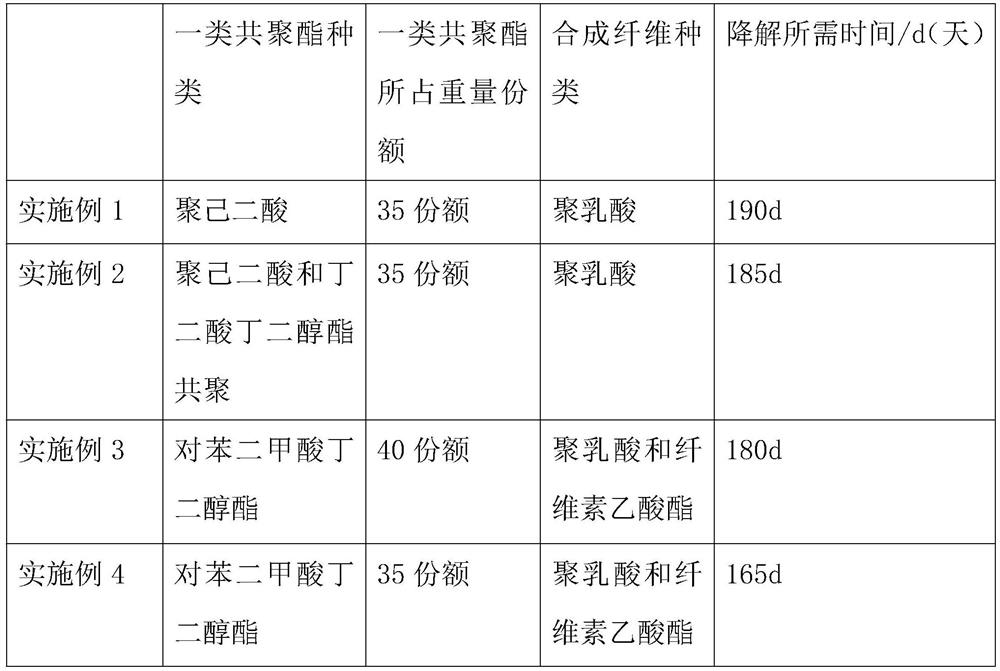

The present invention relates to the technical field of degradable materials, and discloses a degradable mosquito net bag, the mosquito net bag preparation raw materials are degradable materials, and the raw materials comprise a base material, an antioxidant and a reinforcing agent; wherein the base material is prepared from the following raw materials in parts by weight: 10-50 parts of synthetic fiber, 10-50 parts of copolyester and 0-50 parts of starch, and the antioxidant is prepared from the following raw materials in parts by weight: 1-2 parts of an anti-free radical agent and 1-2 parts of a toughening agent. The reinforcing agent is prepared from the following raw materials in parts by weight: 0-3 parts of a lubricating agent, 1-50 parts of filler and 0.04-2.5 parts of polycaprolactone, through a melting and mixing process of copolyester and starch, the weaving limit degradation rate of synthetic production is remarkably improved compared with that of a traditional plastic weaving process, and in the degradation process, the degradation rate of the plastic weaving process is greatly improved. The self-regulation burden of the ecological environment is greatly reduced, so that the environmental protection is obviously improved, and meanwhile, the toughness of the first-class copolyester is greatly improved.

Owner:沧州永阔隆化工有限公司

Process for avoiding uncontrollable coking in processing process of oil-containing grain

PendingCN113854484AAvoid uncontrollable cokingReduce contentFood thermal treatmentStarch gelatinizationProcess engineering

The invention belongs to the technical field of food processing, and particularly relates to a process for avoiding uncontrollable coking in the processing process of oil-containing grain. The process comprises the following steps of: washing an oil-containing grain raw material with water to remove impurities, then sequentially performing soaking, medium-temperature cooking and high-temperature cooking to obtain a cooked material, performing medium-temperature sealed aging treatment on the cooked material to obtain an aged material, and puffing the aged material by using puffing compression equipment to obtain a puffed rod. According to the process, starch is gelatinized and oil is diffused by utilizing medium-temperature and high-temperature staged cooking, and fat and the starch are gradually and physically combined by utilizing a sealed aging method, so that the fat and the starch in the grain form a starch-fat complex in the puffing process, the content of free fat in an extrudate is reduced, and the oil is prevented from being subjected to high temperature to generate uncontrollable coking.

Owner:SHAANXI UNIV OF SCI & TECH

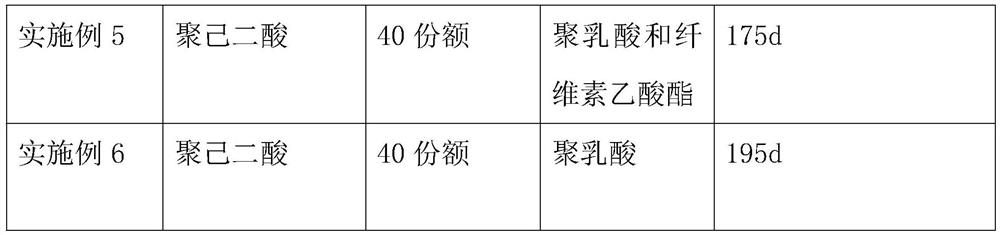

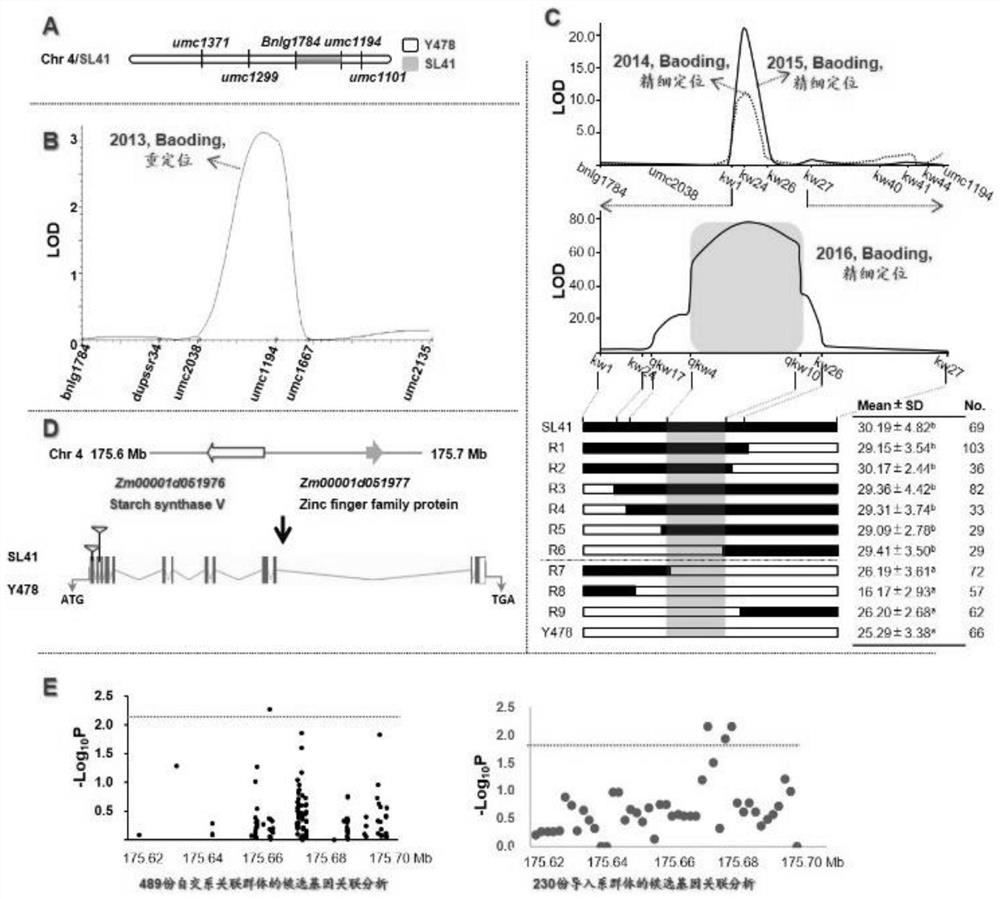

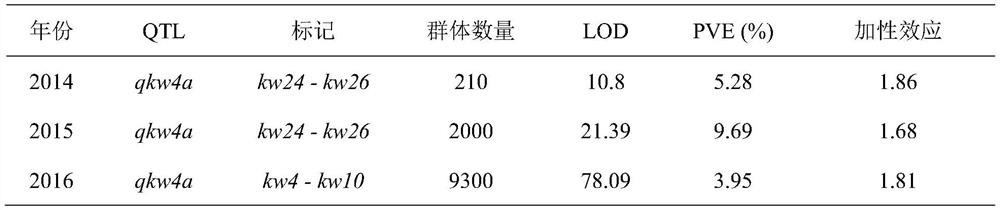

Maize 100-kernel weight major QTL site qkw4a and its candidate genes and applications

ActiveCN112708628BMicrobiological testing/measurementFermentationCytologyCandidate Gene Association Study

Owner:HEBEI AGRICULTURAL UNIV.

A method of preparing a C/gamma-Fe2O3 composite material from acid-regeneration desilication mud cakes

ActiveCN105435738AReduce pollutionSimple processFatty/oily/floating substances removal devicesOther chemical processesDispersitySlurry

A method of preparing a C / gamma-Fe2O3 composite material from acid-regeneration desilication mud cakes is disclosed. The method includes a) adding water into block desilication mud cakes, pulping under heating, and adding furfuryl alcohol, furfural or starch the mass of which is 2-5 times of that of the desilication mud cakes so as to form desilication mud slurry with food dispersity, b) subjecting the slurry in the step a) to spray drying at 100-120 DEG C to obtain coated desilication mud powder, and c) adding the desilication mud powder obtained in the step b) into a heating furnace, raising the temperature to 600-900 DEG C at a heating speed of 2-5 DEG C / min under inert gas protection, maintaining the temperature for 4-8 h after reaching the target temperature, and cooling inside the furnace to obtain the C / gamma-Fe2O3 composite material. The method of preparing the C / gamma-Fe2O3 composite material from the acid-regeneration desilication mud cakes is provided. The starch, the furfuryl alcohol or the furfural which are cheap are utilized for coating, and then thermal cracking is performed to obtain the magnetic carbon material. The method effectively achieves recovery and reutilization of resources.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com