Mint sandwich crisp chips and preparation method thereof

A production method, mint technology, applied in the field of food processing, to achieve the effect of increasing viscosity, increasing viscosity, and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

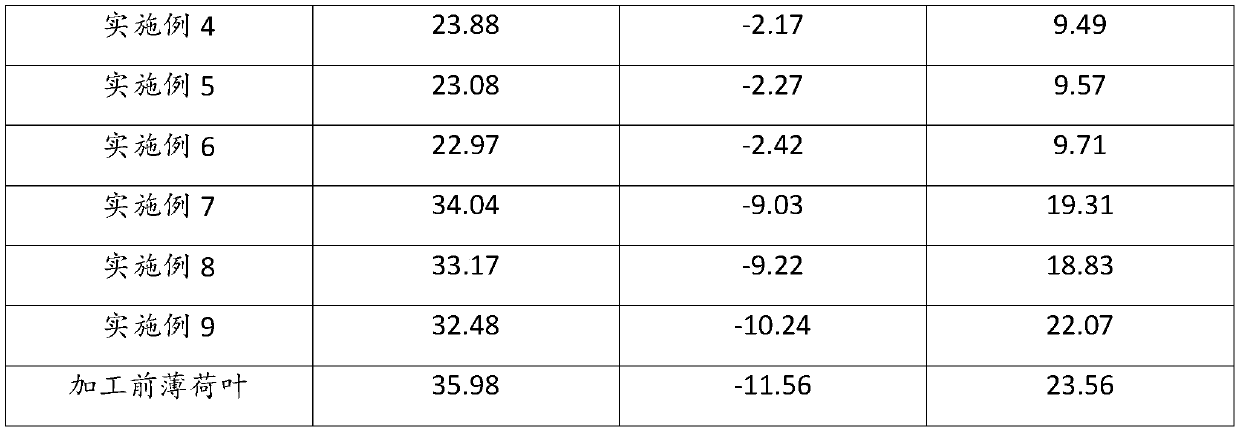

Embodiment 1

[0035] Present embodiment provides a kind of peppermint sandwich chip, and its preparation method comprises the following steps:

[0036] (1) Remove impurities from fresh mint leaves and wash them, centrifuge and drain the water;

[0037] (2) Blanch mint leaves in water at 90°C for 10 seconds, drain and cool;

[0038] (3) mint leaves are put into a beater to be beaten into mint pulp, and then refined through a colloid mill;

[0039] (4) Mix mint pulp and starch at a mass ratio of 1:0.2 to obtain batter, and add seasoning powder for seasoning. The seasoning includes 8% sweetener aqueous solution, 1.0% saline, and It is 8% cream liquid, and the mass ratio of batter to sweetener aqueous solution, salt water, and cream liquid is 1:0.8:0.5:0.8; mature the seasoned batter at 100°C for 25 minutes; the starch is 50-100 mesh Potato starch.

[0040] (5) Take the batter and put it in the mold. The batter forms a cake shape with a thickness of 2mm in the mold. Spread sesame seeds with ...

Embodiment 2

[0045] Present embodiment provides a kind of peppermint sandwich chip, and its preparation method comprises the following steps:

[0046] (1) Remove impurities from fresh mint leaves and wash them, centrifuge and drain the water;

[0047] (2) Blanch mint leaves in water at 70°C for 60 seconds, drain and cool;

[0048] (3) mint leaves are put into a beater to be beaten into mint pulp, and then refined through a colloid mill;

[0049] (4) Mix mint pulp and starch at a mass ratio of 1:0.5 to obtain a batter, and add seasoning powder for seasoning. The seasoning includes 30% sweetener aqueous solution, 1.5% saline, and It is 12% cream liquid, and the mass ratio of batter to sweetener aqueous solution, salt water, and cream liquid is 1:0.5:0.3:0.5; mature the seasoned batter at 105°C for 10 minutes; the starch is 50-100 mesh sweet potato starch.

[0050] (5) Take the batter and place it in the mold. The batter forms a cake shape with a thickness of 0.5mm in the mold. Spread walnut...

Embodiment 3

[0055] Present embodiment provides a kind of peppermint sandwich chip, and its preparation method comprises the following steps:

[0056] (1) Remove impurities from fresh mint leaves and wash them, centrifuge and drain the water;

[0057] (2) Blanch mint leaves in water at 80°C for 30 seconds, drain and cool;

[0058] (3) mint leaves are put into a beater to be beaten into mint pulp, and then refined through a colloid mill;

[0059] (4) Mix mint pulp and starch at a mass ratio of 1:0.35 to obtain batter, and add seasoning powder for seasoning. The seasoning includes 15% sweetener aqueous solution, 1.2% saline, and It is 10% cream liquid, and the mass ratio of batter to sweetener aqueous solution, salt water, and cream liquid is 1:0.6:0.4:0.6; mature the seasoned batter at 100°C for 20 minutes; the starch is 50-100 mesh corn starch.

[0060] (5) Take the batter and put it in the mold. The batter forms a cake shape with a thickness of 1mm in the mold. Spread peanuts with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com