Butyrate starch preparing method

A technology of butyrate and starch, applied in the function of food ingredients, food science, application and other directions, can solve the problems of fast digestion and absorption, low bioavailability, butyric acid odor, etc., to achieve simple operation, good resistance Enzymatic hydrolysis ability, the effect of avoiding absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

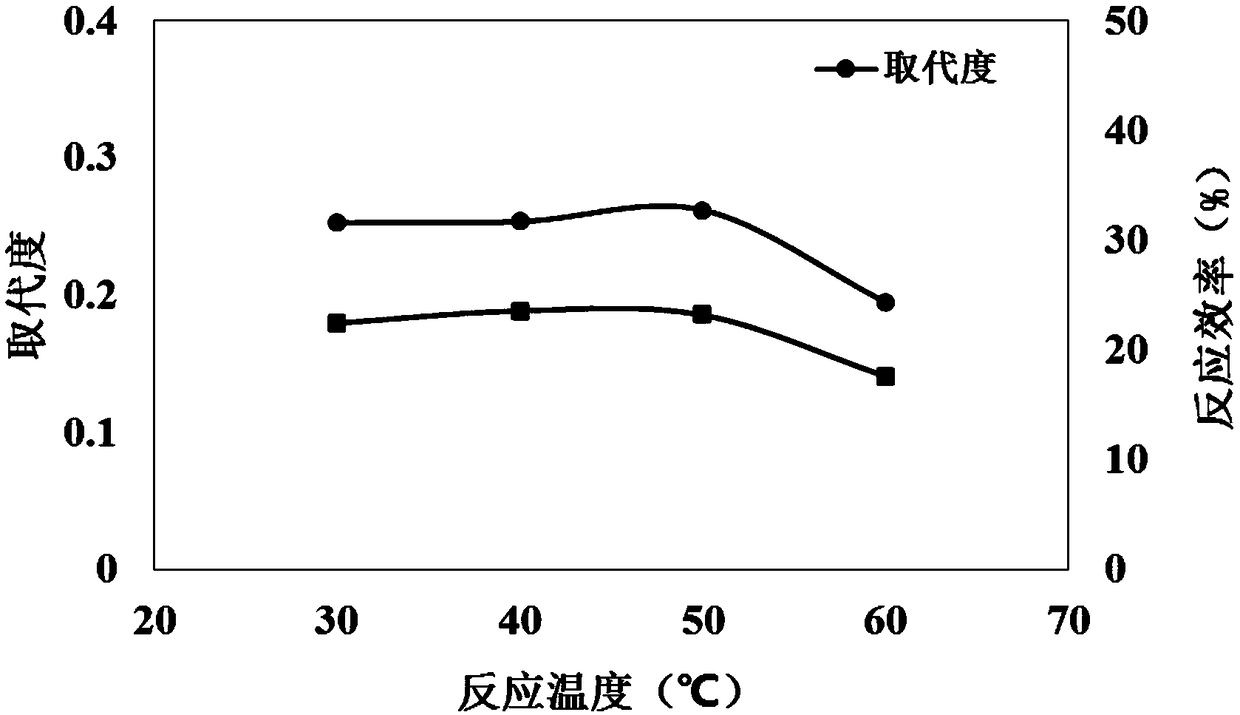

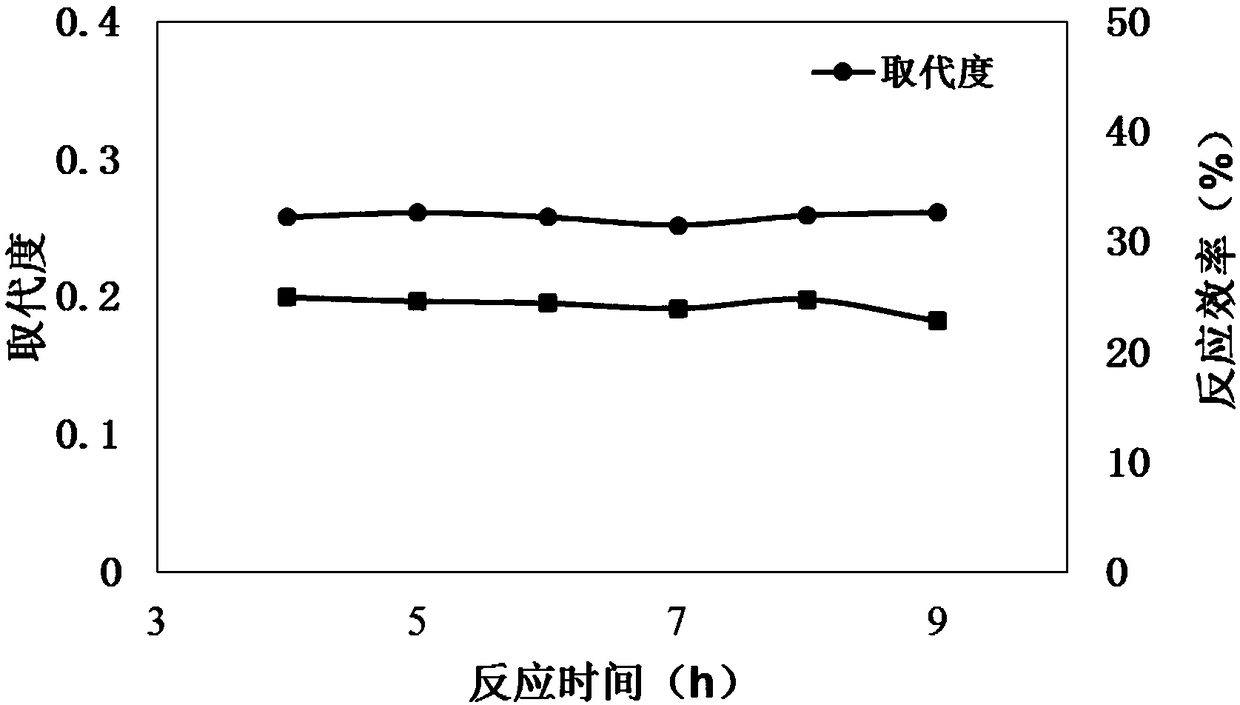

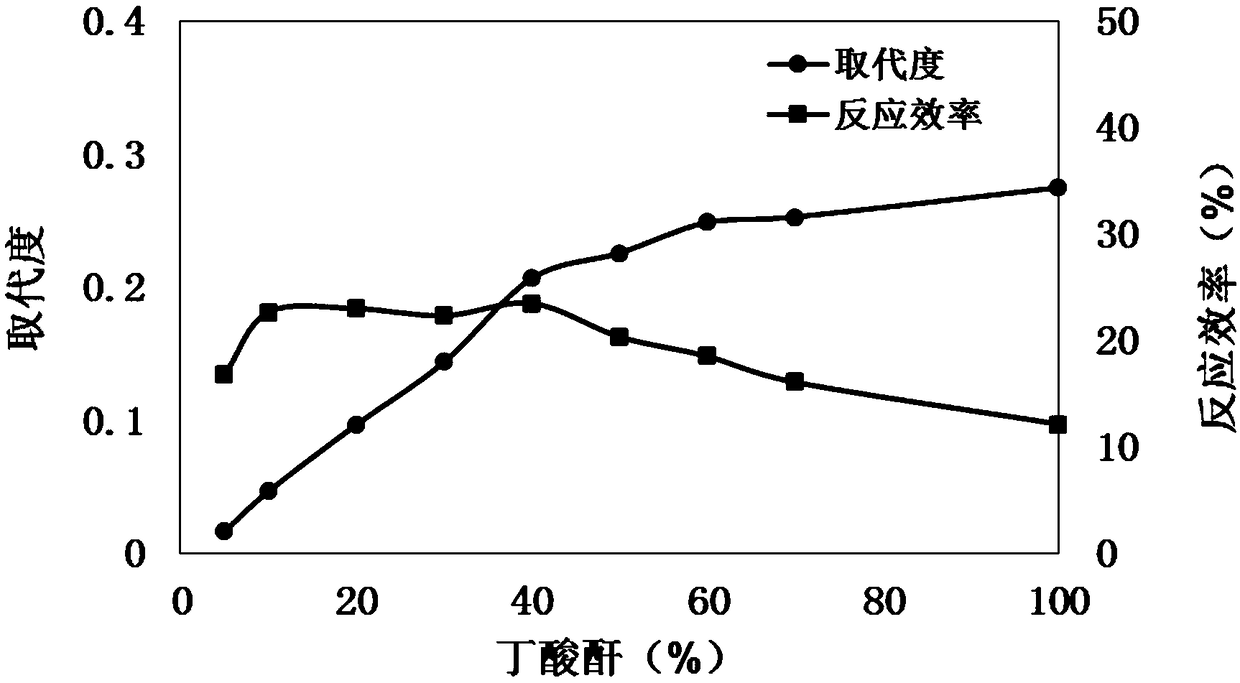

[0044] Add cornstarch into water to make 40% starch milk (w / w). During the reaction, the temperature is controlled by a water bath to be 40° C., and the pH is adjusted with 0.75mol / L sodium hydroxide solution. The pH is controlled at 7.5 to 8.5, and then Add 10mL, 20mL, 30mL, 40mL, and 60mL of butyric anhydride dropwise with a constant-flow pump, add butyric anhydride in about 2 hours, and continue the reaction for 2 hours. Stop the reaction, and adjust the pH to 5.5-6.5 with 1mol / L hydrochloric acid solution. Wash the product with deionized water until neutral, centrifuge, dry the precipitate at 40°C until the water content is less than 14%, grind, pass through a 100-mesh sieve, package and store in a desiccator until use.

[0045] Native starch and butyrate starch with different degrees of substitution were digested in vitro by Englyst method. The starch was gelatinized in an autoclave (121° C.) for 20 min before digestion.

[0046]Table 1 Contents of fast digestible, slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com