Starch-based elastomer as well as preparation method and application thereof

An elastomer and starch-based technology, applied in the field of starch-based elastomers and their preparation, can solve the problems of difficult industrial production, poor mechanical properties of materials, and limited application range, and achieve rapid preparation, good mechanical properties, Realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

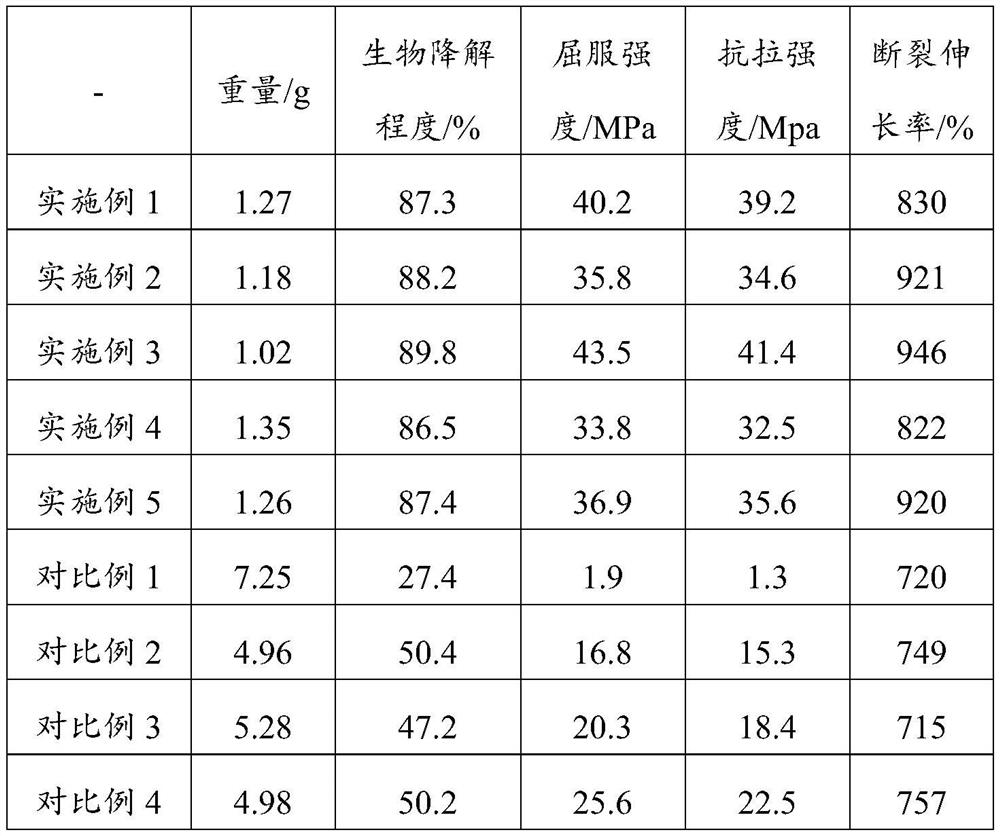

Examples

preparation example Construction

[0065] The preparation method of modified starch in the embodiment of the present invention is as follows:

[0066] First, mix 2 parts by weight of starch and 100 parts by weight of water at 90°C, then add 5 parts by weight of iron acetate, and react at room temperature (about 25°C) for 2 hours to obtain modified starch.

Embodiment 1

[0067] Embodiment 1 of the present invention is: starch-based elastomer and preparation method thereof:

[0068] Starch-based elastomers include the following raw materials: 40 parts of polypropylene carbonate polyol (JLB-B2350, Jiangsu Jinlong); 10 parts of polycaprolactone diol (BASF PCL1000); 10 parts of modified starch; 20 parts of straw; (nano-titanium dioxide) 1 part; Catalyst (stannous octoate) 0.5 part; Antioxidant (BASF, antioxidant 1010, CAS number: 6683-19-8) 3 parts; Chain extender (isophorone diisocyanate, worship Er, CAS number: 4098-71-9) 5 parts and plasticizer (glycerin) 1 part.

[0069] The preparation method of above-mentioned starch-based elastomer, comprises the following steps:

[0070] S1. Put the modified starch and straw into a high-speed mixer at a speed of 300rpm / min, and stir for 10 minutes, so that the modified starch and straw are evenly mixed to form a premix;

[0071] S2. Add the premix, filler, catalyst, antioxidant, chain extender and plasti...

Embodiment 2

[0073] Embodiment 2 of the present invention is: starch-based elastomer and preparation method thereof:

[0074] Starch-based elastomers include the following raw materials: 50 parts of polypropylene carbonate polyol (JLB-H2200, Jiangsu Jinlong); 25 parts of polycaprolactone diol (BASF PCL1000); 25 parts of modified starch; 40 parts of straw; (carboxylated nano-titanium dioxide) 5 parts; catalyst (stannous octoate) 1 part; antioxidant (BASF Tinuvin B75ED) 5 parts; chain extender (BASF T-80) 10 parts and plasticizer (urea) 3 parts.

[0075] The preparation method of above-mentioned starch-based elastomer, comprises the following steps:

[0076] S1. Put the modified starch and straw into a high-speed mixer at a speed of 300rpm / min, and stir for 5-10 minutes, so that the modified starch and straw are evenly mixed to form a premix;

[0077] S2. Add the premix, filler, catalyst, antioxidant, chain extender and plasticizer prepared in step S1 into the high-speed mixer in turn, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com