a kind of al 2 o 3 Preparation method and application of porous ceramics

A technology of porous ceramics and pore-forming agent, which is applied in the field of preparation of Al2O3 porous ceramics, can solve the problems of complex preparation process, low pore-forming ability, limited gas amount, etc., and achieves simple preparation process, good compressive strength, and good reduction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

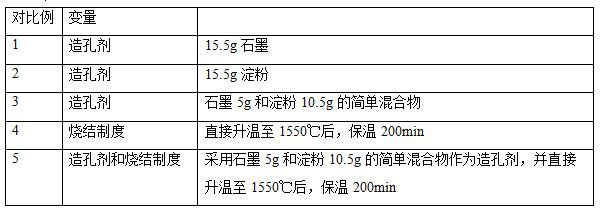

Examples

Embodiment 1

[0032] a kind of Al 2 o 3 A method for preparing porous ceramics, comprising the steps of:

[0033] (1) Prepare pore-forming agent A: Prepare 5g of graphite and 10.5g of starch, dissolve the starch to obtain a starch solution, mix the graphite and 20% ethanol solution evenly to obtain a mixed solution, and drop the starch solution into the mixed solution under magnetic stirring After standing and layering to remove the supernatant, the precipitate was washed 3 times with deionized water and then placed in a drying oven at 100°C for 5 hours to obtain starch-coated graphite as a pore-forming agent.

[0034] (2) Mixing: weigh 50.26g Al 2 o 3 and 19.74g MgO, mixed with the pore former A obtained above for 30min in a ball mill, the ratio of material to ball during mixing was 1:2.

[0035] (3) Molding: Press a Φ16.5mm porous ceramic disc: Weigh 1g of the mixed material and mix it into a disc-shaped mold, apply a pressure of 50N to the mixed material, hold the pressure for 30s, and...

Embodiment 2

[0041] This example is basically the same as Example 1, except that the sintering system of this example is as follows: first, the temperature is raised to 250°C at a heating rate of 5°C / min, and the temperature is kept at 35min; The temperature was raised to 600°C at a rate of 30 minutes, and finally the temperature was raised to 1550°C at a rate of 3°C / min, and held at 120 minutes. Then air-cooled and cooled to room temperature to obtain Al 2 o 3 porous ceramics.

[0042] For the Al obtained in this example 2 o 3 The porous ceramics were tested according to the method in Example 1: the test results are shown in Table 2 below.

Embodiment 3

[0044] This example is basically the same as Example 1, except that the sintering system of this example is as follows: first, the temperature is raised to 75°C at a heating rate of 5°C / min, and the temperature is kept for 35 minutes; Raise the temperature to 250°C and keep it for 35 minutes; then raise the temperature to 600°C at a rate of 5°C / min and keep it for 40 minutes; then raise the temperature to 1400°C at a rate of 3°C / min and keep it for 60 minutes; The heating rate was raised to 1550°C and kept for 120 minutes. Then air-cooled and cooled to room temperature to obtain Al 2 o 3 porous ceramics.

[0045] For the Al obtained in this example 2 o 3 The porous ceramics were tested according to the method in Example 1: the test results are shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com