Balanced hydro-pneumatic suspension with built-in air chamber

A technology of oil and gas suspension and air chamber, applied in the field of hydraulic machinery, can solve the problems of multi-car body layout space, increase production and manufacturing costs, needs, etc., and achieve the effects of reducing manufacturing costs, simplifying structural solutions, and solving excessive losses along the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

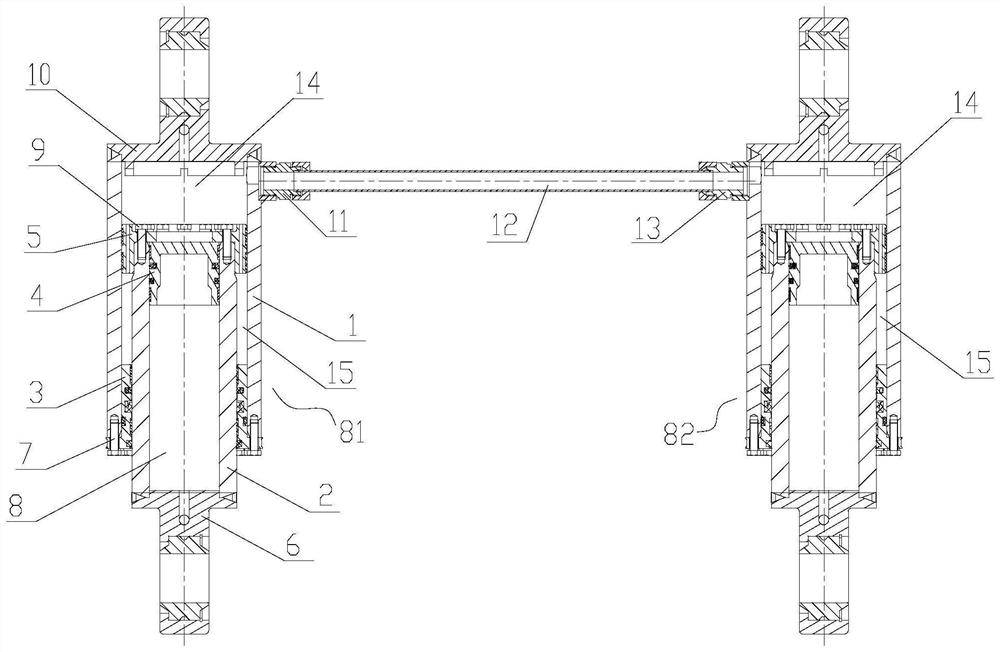

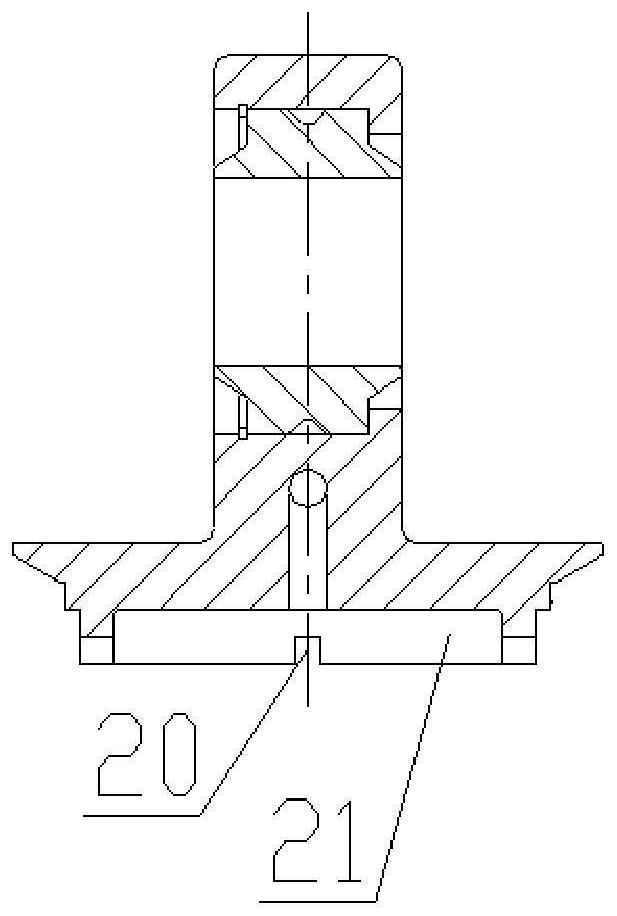

[0049] This embodiment provides a balanced oil-air suspension with a built-in air chamber, see the attached figure 1 , including: two oil-gas springs, a front spring joint 11, a rear spring joint 13 and a balance pipeline 12;

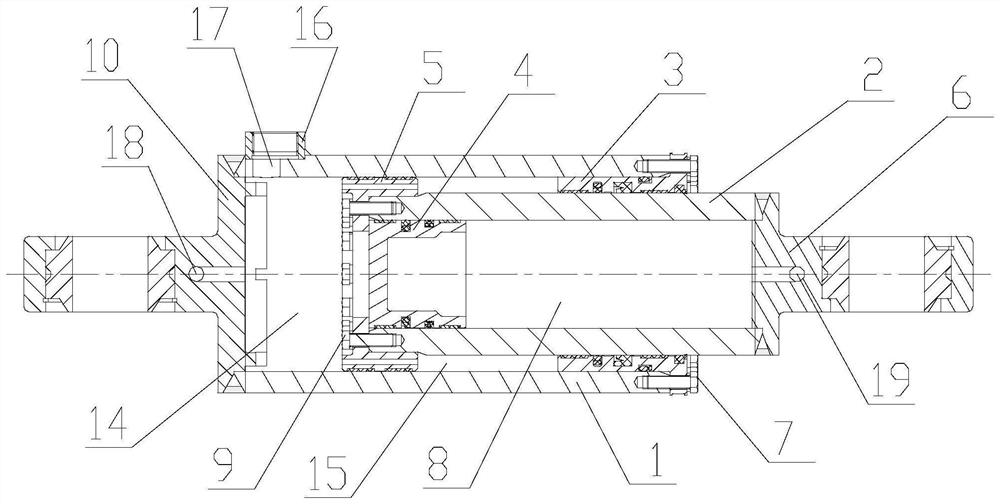

[0050] The two oil-gas springs are respectively a front oil-gas spring 81 and a rear oil-gas spring 82; the oil-gas springs are all hollow structures, and their inner chambers are the main oil chamber 14, and piston rods 2 are installed in the inner chambers of the oil-gas springs. , the piston rod 2 is a hollow structure, the piston rod 2 is provided with a floating piston 4, so that the inner cavity of the piston rod 2 forms a built-in air chamber 8;

[0051] The front oil-gas spring 81 is connected to one end of the balance pipeline 12 through the front spring joint 11, and the rear oil-gas spring 82 is connected to the other end of the balance pipeline 12 through the rear spring joint 13; the main oil chamber 14 of the front oil-gas spring 81 passes...

Embodiment 2

[0066] In this embodiment, on the basis of Embodiment 1, the main piston 5 is replaced with a sealed piston 61; Figure 7-9 , the sealed piston 61 is a cylindrical structure with one end open and one end closed; more than two axial through holes B are processed on the closed end of the sealed piston 61, and the axial through holes B are throttle holes 51; two third guide strips 53, a third oil seal 54 and a fourth oil seal 55 are provided on the outer circumference of the sealed piston 61; the third oil seal 54 and the fourth oil seal 55 are located in the two third Between the guide belts 53;

[0067] The closed end of the piston with seal 61 is fixed on the upper end of the piston rod 2 by the piston bolt 9 arranged in the circumferential direction, and the upper end opening is closed; the open end of the piston with seal 61 is located at the other end of the annular gap, with a seal The third guide band 53 on the piston 61 is in contact with the inner circumferential surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com