Wet cooling tower

A wet cooling and tower body technology, applied in the field of cooling towers, can solve the problems of easy dust collection, regular cleaning, and large resistance of finned tubes, and achieve the effects of simple installation, high electrothermal conversion rate, and improved fog elimination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

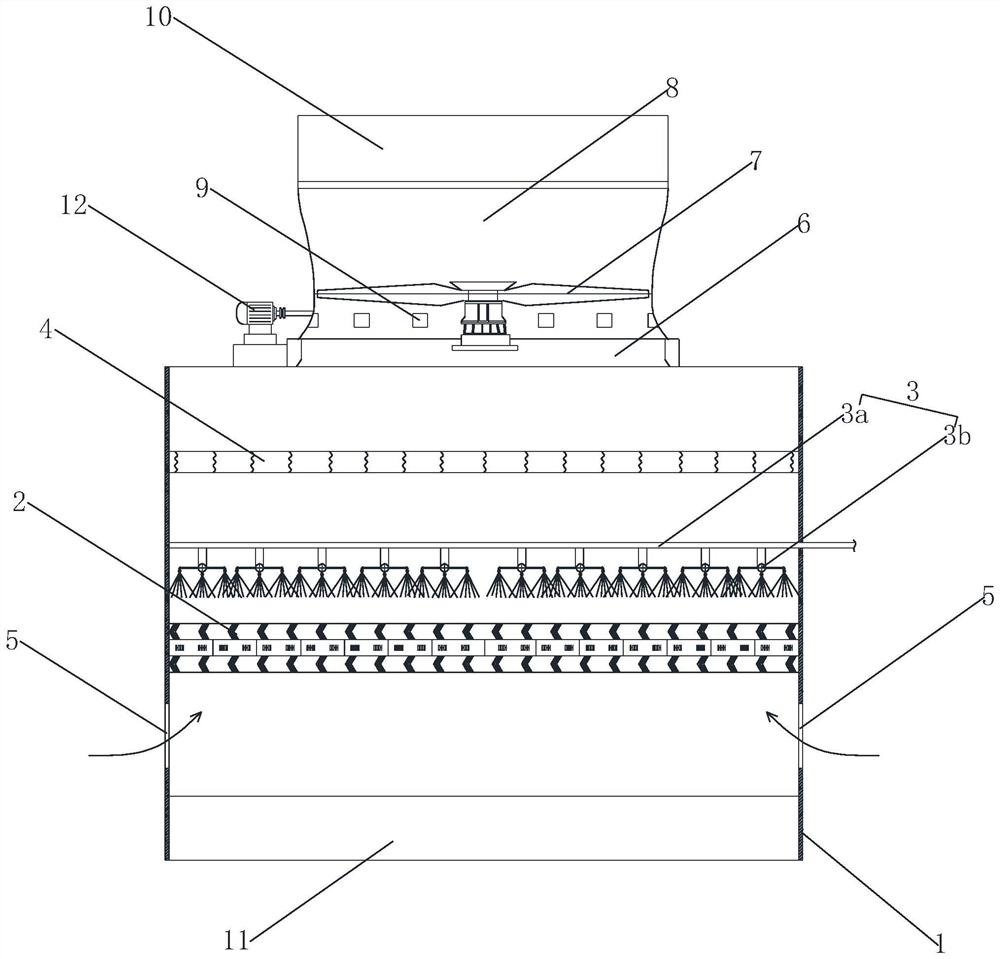

[0019] like figure 1 As shown, a wet cooling tower includes a tower body 1, a packing layer 2, a spray device 3 and a water receiver 4 are arranged in the tower body 1 sequentially from bottom to top, and the spray device 3 includes a spray pipe 3a and several The nozzle 3b connected with the spray pipe 3a, the tower wall below the packing layer 2 is provided with an air inlet 5, the top of the tower body 1 is provided with an air outlet 6, and the bottom of the tower body 1 is provided with a sump 11, the sump 11 is located at the entrance Below the tuyere 5, the air outlet 6 is provided with a fan 7, the fan 7 is driven by a motor 12, the fan 7 is located in the air cylinder 8, and the top of the air cylinder 8 is provided with an air exhaust port 10. The structures of the above-mentioned wet cooling towers are existing There are technologies, so I won't go into details here. The electrothermal film 9 is evenly arranged on the outer circumferential wall or the inner circumf...

Embodiment 2

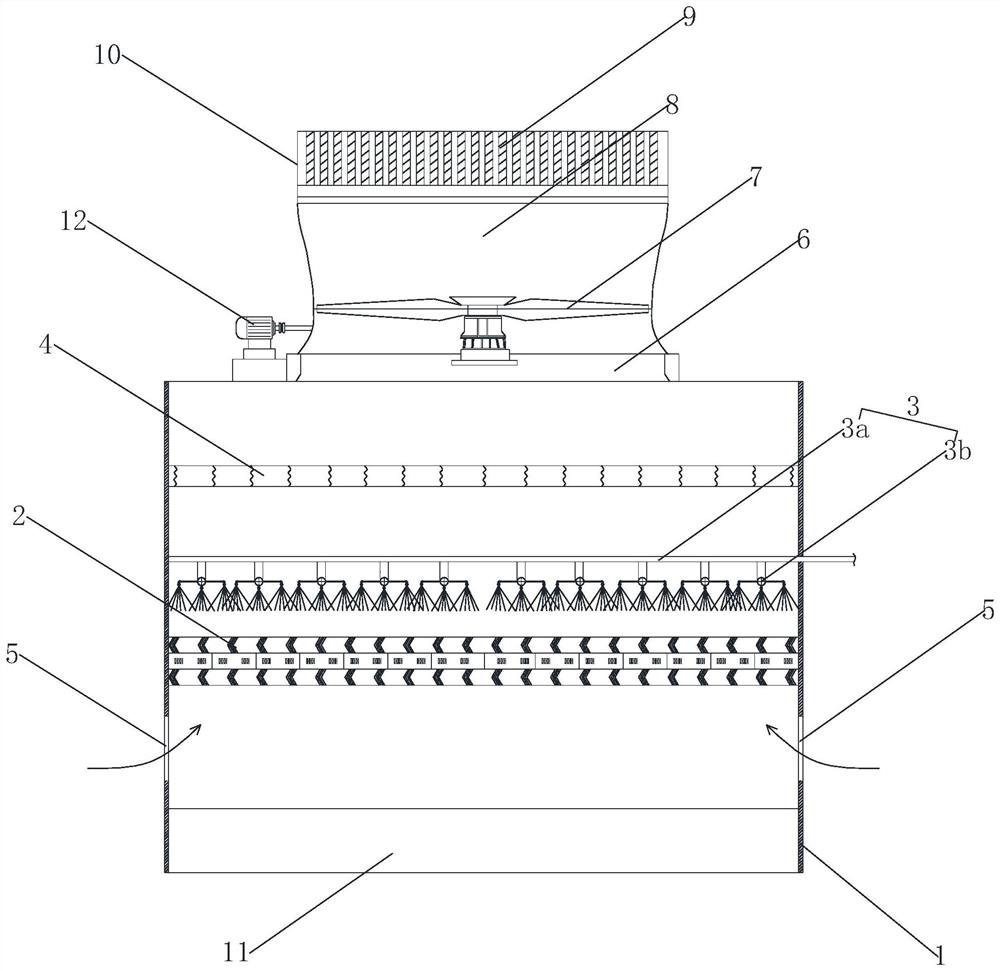

[0022] like figure 2 As shown, the structure of the wet cooling tower is the same as that of Embodiment 1, except that the electrothermal film 9 is arranged at the air outlet 10 above the air cylinder 8 instead of the bottom of the air cylinder 8 .

[0023] The working principle of this embodiment is: the circulating hot water is distributed to several nozzles 3b through the spray pipe 3a, sprayed evenly on the packing layer 2 through the several nozzles 3b, and the sprayed hot water forms a thin film on the packing layer 2. Under the suction of the fan 7, the dry and cold air outside the tower enters the tower from the air inlet 5 to exchange heat with the packing layer 2. The sprayed hot water evaporates and cools to become cold water and enters the sump 11. The dry and cold air in the tower passes through the packing layer 2 and the packing layer 2. After spraying hot water for heat exchange, the saturated hot and humid air continues to rise, and the water droplets formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com