MicroLED chip and manufacturing method thereof

A manufacturing method and chip technology, applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as chip efficiency reduction, life shortening, device failure, etc., and achieve the effects of distribution optimization, effective resistance reduction, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

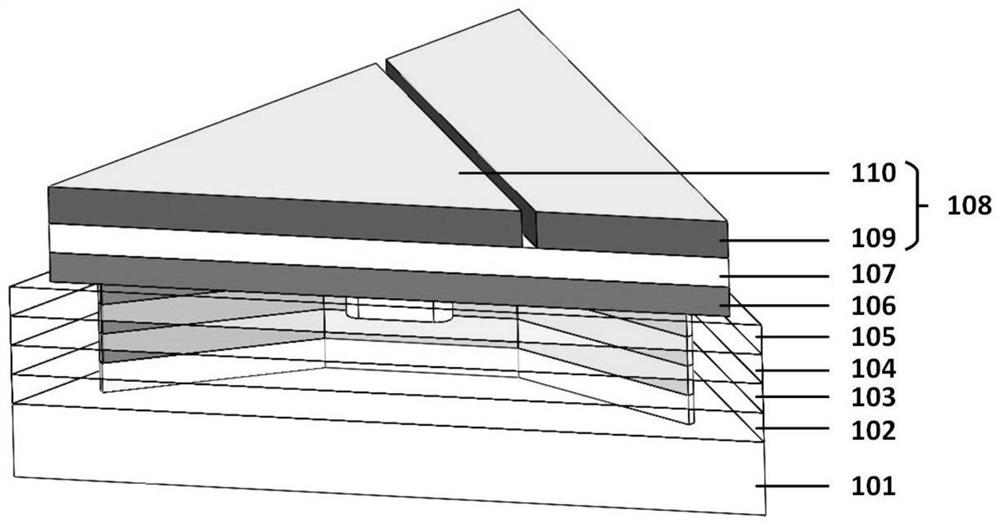

[0045] Embodiment 1 provides a method for manufacturing a MicroLED chip, see figure 1 , including the following steps:

[0046] Step 1, growing the epitaxial layer of the Micro LED chip on the growth substrate, the epitaxial layer includes an n-type semiconductor layer, a multi-quantum well layer and a p-type semiconductor layer in sequence from bottom to top.

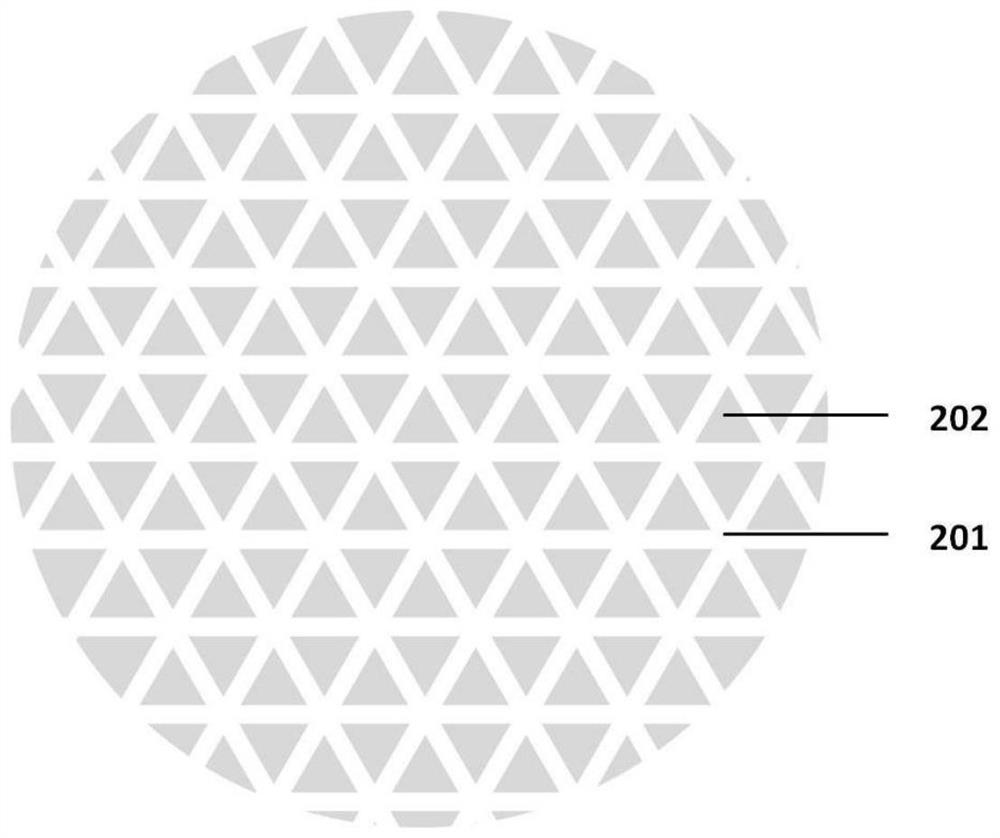

[0047] Specifically, see figure 1 , figure 2 The epitaxial layer 202 is grown on a sapphire substrate by MOCVD method, and the epitaxial layer 202 includes a 2-4 μm n-GaN layer 101, 5-12 pairs of InGaN / GaN multiple quantum well layers 102 and 80 from bottom to top - 300nm Mg-doped p-GaN layer 103; in each InGaN / GaN pair, the thickness of InGaN is 1-3nm, and the thickness of GaN is 8-15nm.

[0048] Step 2, etching chip isolation trenches on the epitaxial layer, and forming an epitaxial layer including a plurality of mesa regions in a triangular shape after the etching is completed.

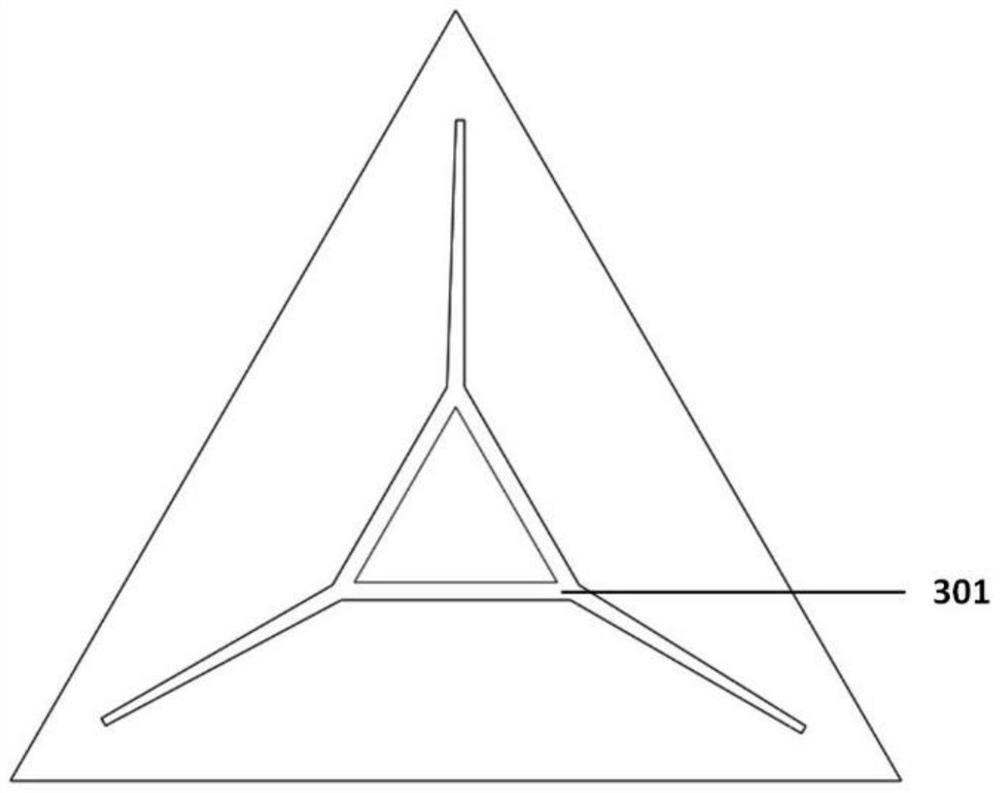

[0049] Specifically, such as ...

Embodiment 2

[0067] Embodiment 2 provides a Micro LED chip, which is prepared by using the manufacturing method of the Micro LED chip provided in Embodiment 1.

[0068] see Figure 1 to Figure 6 , the chip structure of the Micro LED chip is a thin-film flip-chip structure, and the shape of the Micro LED chip is a triangle.

[0069] The growth substrate of the Micro LED chip is a sapphire substrate, and after the chip is manufactured, the sapphire growth substrate is peeled off. The epitaxial layer grown on the sapphire substrate is an n-type semiconductor layer, a multi-quantum well layer, and a p-type semiconductor layer in sequence from bottom to top. The epitaxial layer is etched into a triangular-shaped structure including a plurality of mesa regions.

[0070] Specifically, the epitaxial layer 202 of the Micro LED chip is an n-GaN layer 101 , an InGaN / GaN multiple quantum well layer 102 and a p-GaN layer 103 in sequence.

[0071] On the p-GaN layer 103 is an ITO layer 104 , the ITO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com