Quick drying device for artificial flower production

A technology of fast drying and artificial flower, applied in the direction of drying gas arrangement, drying, application, etc., can solve the problems of increasing the production cost of artificial flower, increasing the drying time, etc., so as to improve the drying effect, improve the drying uniformity, and reduce the production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

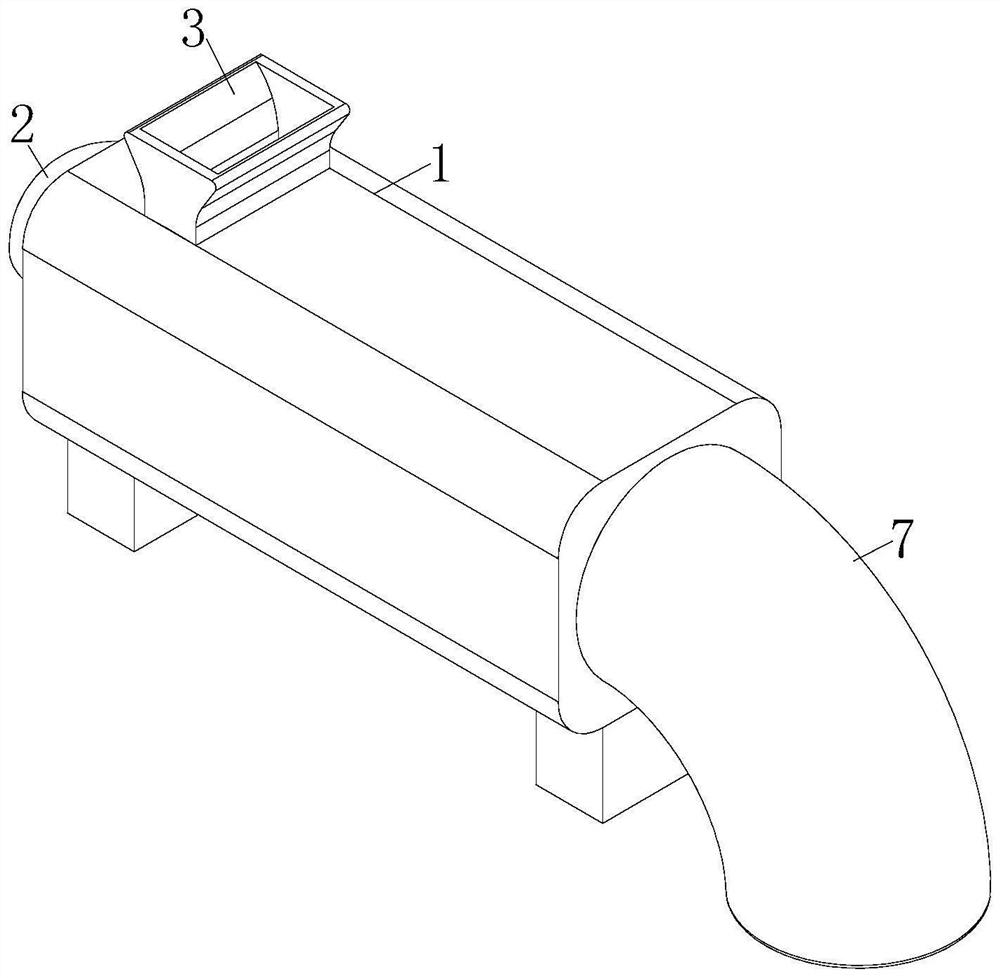

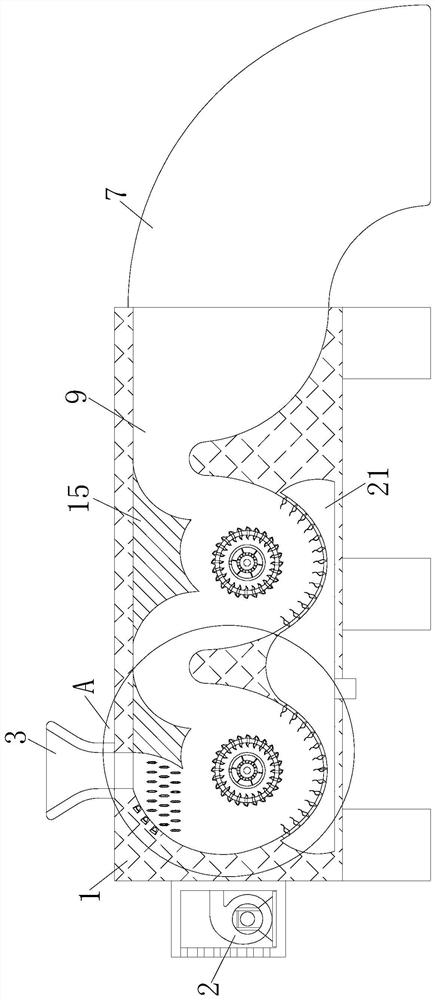

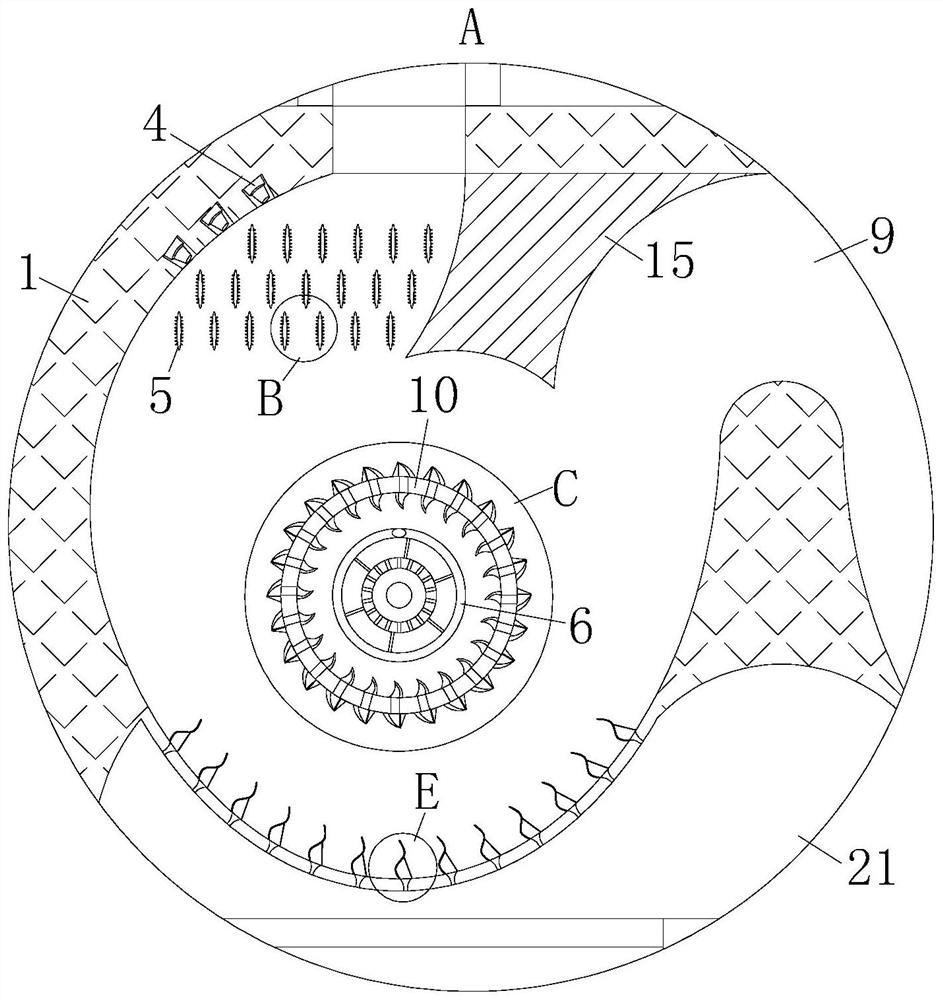

[0031] Such as Figure 1 to Figure 3 As shown, a quick drying device for artificial peanut production described in the embodiment of the present invention includes a housing 1, a blower 2, a feeding port 3, a high-pressure nozzle 4, an elastic strip 5, a heating coil 6 and a collecting bag 7; The top of one end of the housing 1 is fixedly connected with a feeding port 3 , the inner ring of the feeding port 3 is connected to the inner ring of the housing 1 , and the end of the housing 1 close to the feeding port 3 is fixedly connected with a blower 2 , the interior of the housing 1 is fixedly connected with a plurality of elastic strips 5, which are distributed alternately between the plurality of elastic strips 5, the elastic strips 5 are located at the bottom of the feeding port 3, and the interior of the housing 1 is close to The top of one side of the blower 2 is provided with a plurality of high-pressure nozzles 4, and the high-pressure nozzles 4 communicate with the air out...

Embodiment 2

[0041] Such as Figure 8 As shown in Comparative Example 1, another embodiment of the present invention is: the middle part of the elastic sheet 19 is fixed with a plurality of drainage lines 23, and the bottom ends of the drainage lines 23 are in contact with the inner wall of the water collection hole 22 Fixed connection; through the drainage line 23, the water droplets scraped off the elastic sheet 19 are accurately guided into the water collection hole 22, thereby improving the accuracy and efficiency of collecting water droplets.

[0042] When working: the washed petals and leaves are added to the shell 1 from the feeding port 3, and the blower 2 passes a part of the high-pressure air into the high-pressure nozzle 4, and sprays out from the high-pressure nozzle 4 to blow the petals and leaves. The blades pass through the elastic strips 5, and when the high-speed air flow passes through the elastic strips 5, the elastic strips 5 vibrate to further disperse the petals and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com