Crystal growth tank and method for removing mixed crystals at bottom of tank

A crystal growth and miscellaneous crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of spontaneous nucleation, stop of crystal growth process, large supersaturation, etc., to improve the success rate and prevent miscellaneous The effect of crystal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

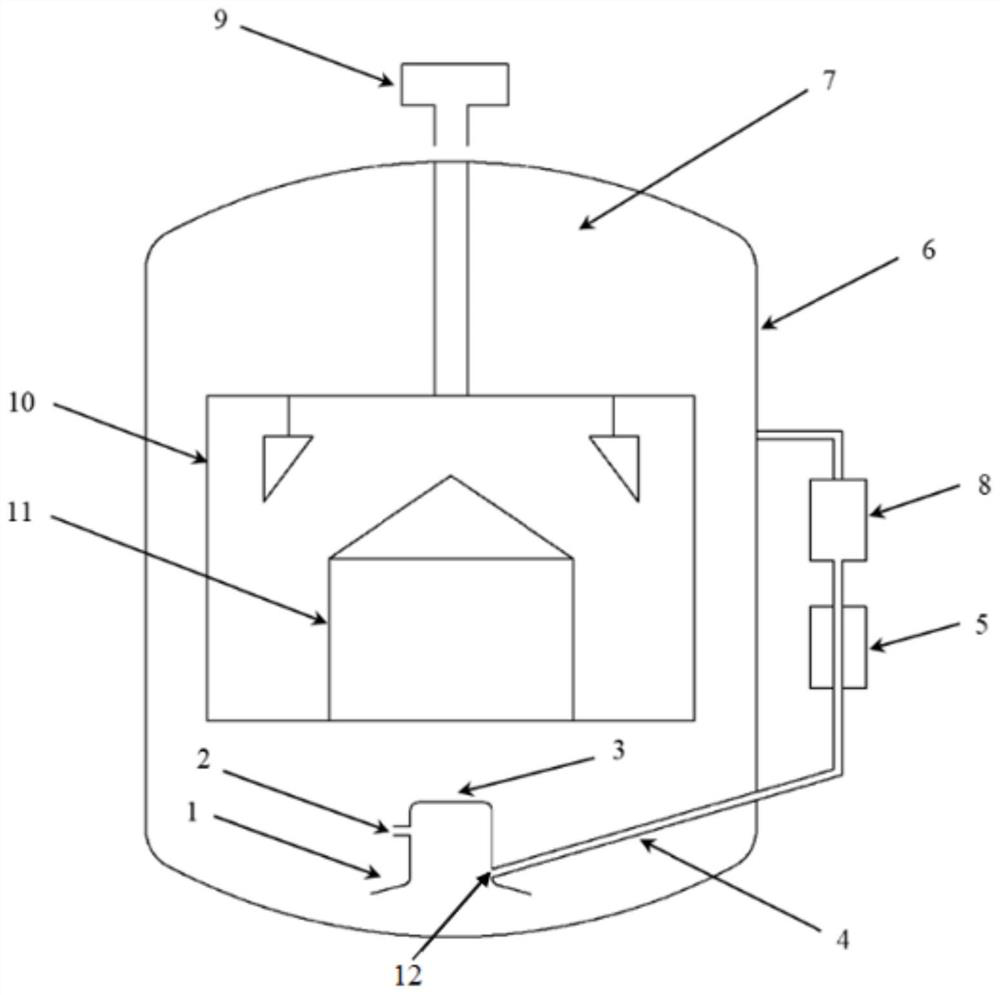

[0035] A crystal growth tank, such as figure 1 As shown, it includes a miscellaneous crystal dissolution cover 3, a movable connecting pipe 4, a heater 5, a tank body 6, a continuous filter device 8, a stirring motor 9, and a crystal carrier 10;

[0036] The continuous filtering device 8 is located outside the tank body, including a circulating pump and a filter element;

[0037] A stirring motor 5 is provided at the center of the top of the tank body 6, and the connecting rod of the stirring motor 5 passes through the top of the tank body 6 and enters the crystal growth solution cavity 7, and then is connected with a crystal carrier 10;

[0038] The crystal is erected inside the tank body, and the crystal carrier 10 and the bottom of the tank body 6 are provided with a miscellaneous crystal dissolving cover 3, and the cover opening of the miscellaneous crystal dissolving cover is towards the bottom of the tank body, and the diameter of the cover opening is 50mm. Crystal diss...

Embodiment 2

[0044] A method for removing impurities at the bottom of the tank when preparing KDP crystals, using the crystal growth tank described in Embodiment 1, the crystal carrier 10 is rotated inside the tank body 6 to stir the crystal growth solution, and the stirring rotation cycle mode is forward rotation-stop -Reverse rotation, forward rotation for 30s, stop rotation for 5s, reverse rotation for 30s, repeat, the rotation speed is 30r / min. After the crystal growth solution is circulated and filtered through the continuous filter device 8 , the solution is heated to 15° C. above the saturation point by the heater 5 , and enters the miscellaneous crystal dissolution cover 3 through the movable connecting pipe 4 .

[0045] When miscellaneous crystals appear during the growth process, after finding the position of the miscellaneous crystals, control the mobile connecting pipe 4 to place the miscellaneous crystals in the miscellaneous crystal dissolution cover 3, apply pressure so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com