Splicing type steel sleeve and mortise and tenon joint steel-wood combined joint

A steel-wood combination and splicing technology, used in truss structures, joists, girders, etc., to achieve the effect of light weight and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

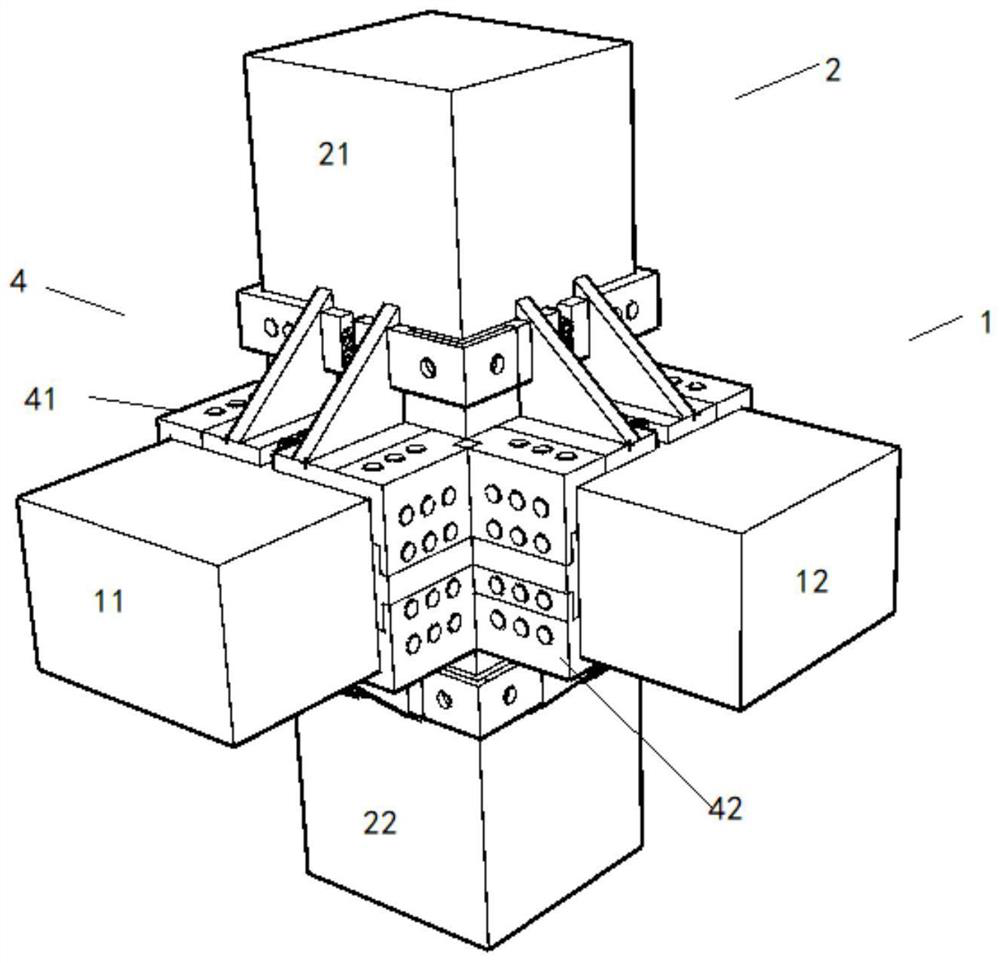

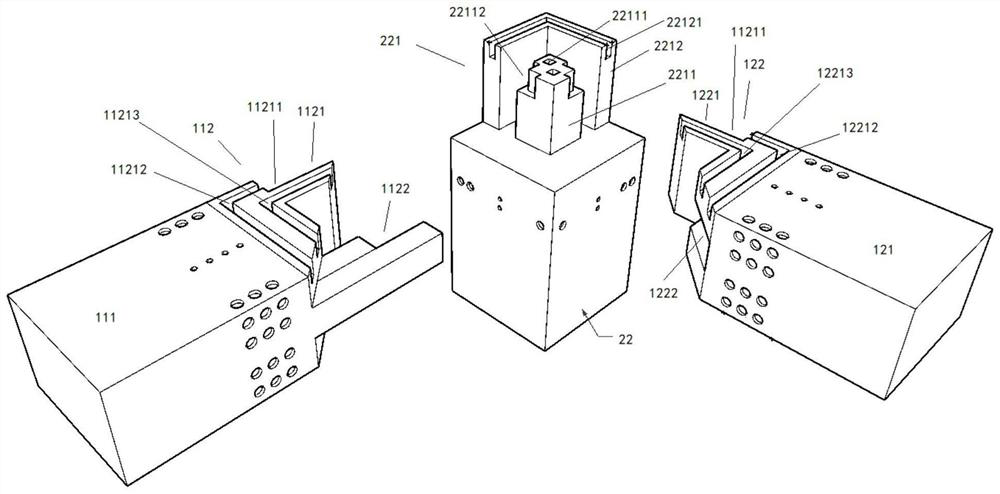

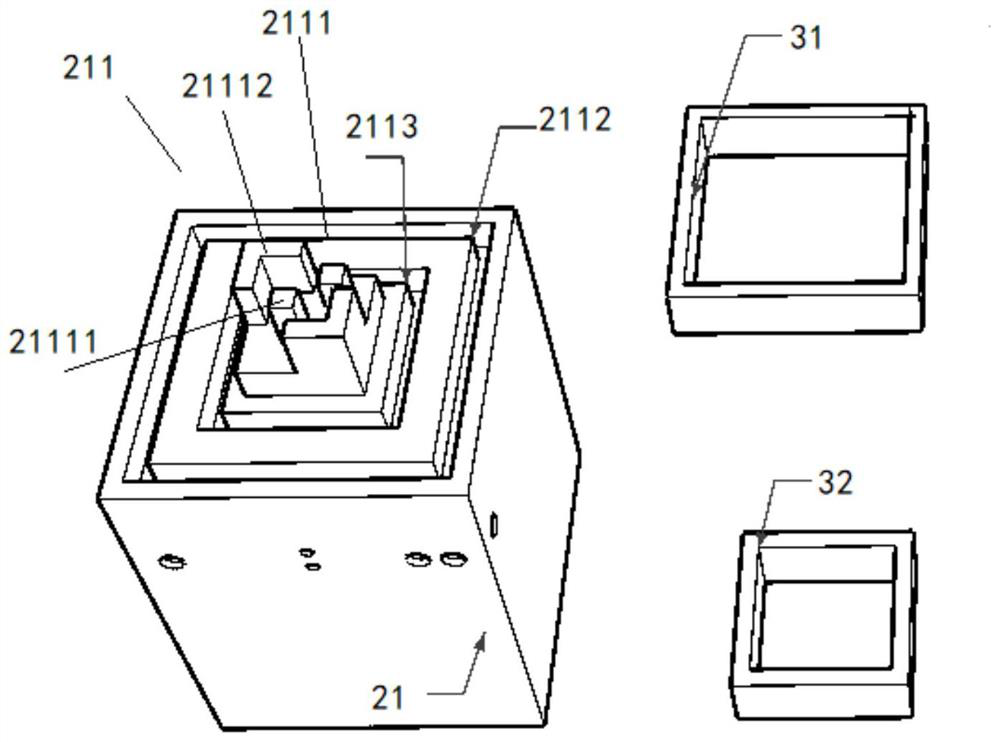

[0031] combined with Figure 1-8 The embodiments of the present invention will be described in detail.

[0032] Such as Figure 1-2 As shown, a spliced steel sleeve and mortise-and-tenon steel-wood composite joint in this embodiment includes a wooden beam 1 and a column 2, and a beam-column joint is formed between the wooden beam 1 and the column 2, and the column 2 includes an upper column 21 and a lower column 21. The column 22, the upper column 21 and the lower column 22 are connected by tenon and tenon. A steel sleeve plate is also sleeved between the upper column 21 and the lower column 22 . The steel casing includes a first square steel casing 31 inside and a second square steel casing 32 outside. The wooden beam 1 includes a first wooden beam 11 and a second wooden beam 12 , and the first wooden beam 11 and the second wooden beam 12 are connected by tenon and tenon. The top of the lower column 22 is provided with a shank connecting portion 221 . A tenon joint 211...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap