Internal welding of tubes and profiles

A profile and welding head technology, applied in the field of internal welding of pipes and profiles, which can solve problems such as cantilever deflection, affecting the welding process and weld geometry, as well as weld quality, rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

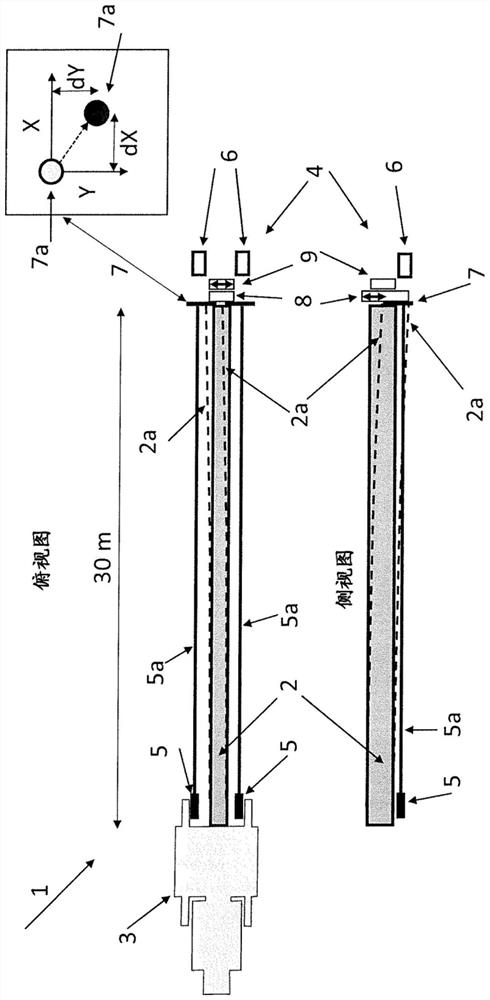

[0028] In the device 1 shown, the boom 2 is fastened to a suspension 3 . The tubes or profiles to be welded are not shown as they are not necessary for understanding the invention. However, it is conceivable that the device 1 is located in the middle of a pipe or profile. The deflection of the cantilever 2 due to magnetic or temperature effects is shown by dashed line 2a. The top view is along the horizontal direction, and the side view is along the vertical direction. A welding head 4 is mounted on the end of the boom 2 , movable vertically and horizontally perpendicular to the axis of the boom 3 , wherein the welding head 4 itself is not shown. Two lasers 5 are fixed on the suspension 3 . Each laser beam 5 a is aimed at two cameras 6 fixed on the ends of the cantilever 3 . A transparent, preferably white-coloured plate 7 is arranged in the beam path between the laser 5 and the camera 6 , wherein there can be a pair of cameras for each laser and naturally also a plate 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com