Tourmaline mixture, Tourmaline mixed coating, preparation method and application

A mixture and coating technology, applied in coating, antifouling/underwater coating, disinfection and other directions, can solve the problems of complex operation, pollution and high cost of the preparation method, and achieve the simple and easy operation of the preparation method, high release concentration, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

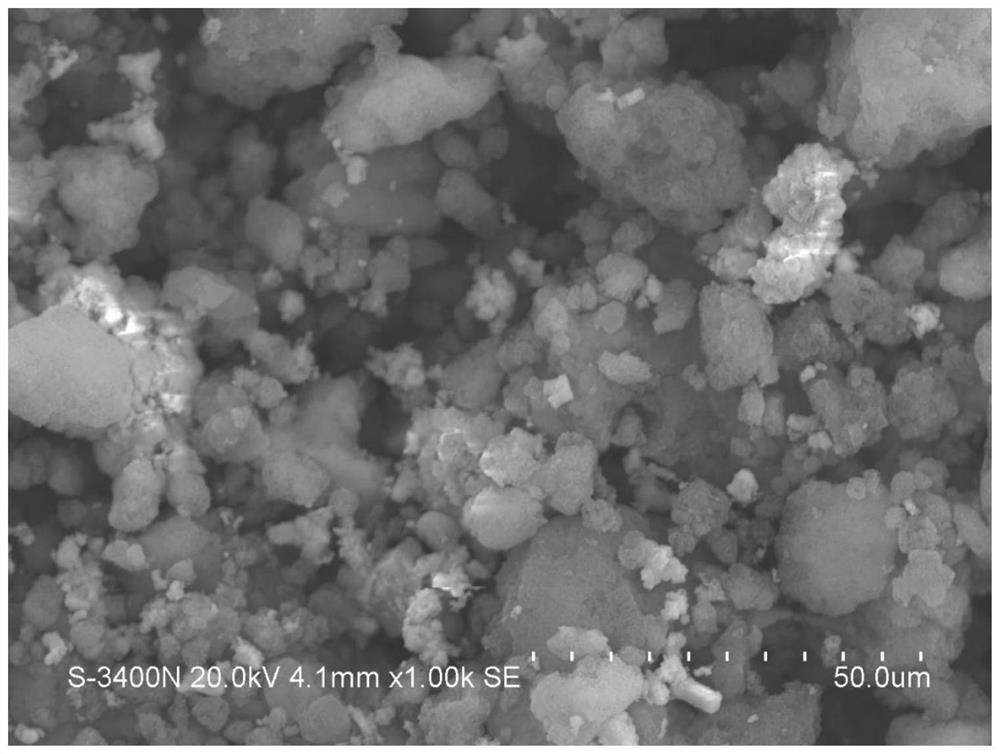

Embodiment 1

[0058] Step 1. Prepare Tourmaline Mixture

[0059] Add tourmaline powder, silicon dioxide powder, and surfactant (CTAB: cetyltrimethylammonium bromide) into a mixed solvent (volume ratio of water and absolute ethanol: 4:1), and ultrasonically for 10 minutes. ;

[0060] Among them, the tourmaline powder particle size D50 is 10 μm to 20 μm, and the solid content is 1%; the silicon dioxide powder particle size D50 is 20 μm to 30 μm, and the solid content is 2%; the mass ratio of tourmaline powder to silicon dioxide powder is 1:2; the mass of the surfactant accounts for 1% of the total mass of the tourmaline mixture.

[0061] Step 2. Prepare Tourmaline Hybrid Coating

[0062] Spray the tourmaline mixture prepared in step 1 on a glass plate, and place it in an oven to dry.

[0063] Among them, the spraying adopts the model YZ-K5 blue light atomizing gun, and the spraying area is 150cm 2 (containing 0.05g of tourmaline mixture), the drying temperature is 70°C, and the drying tim...

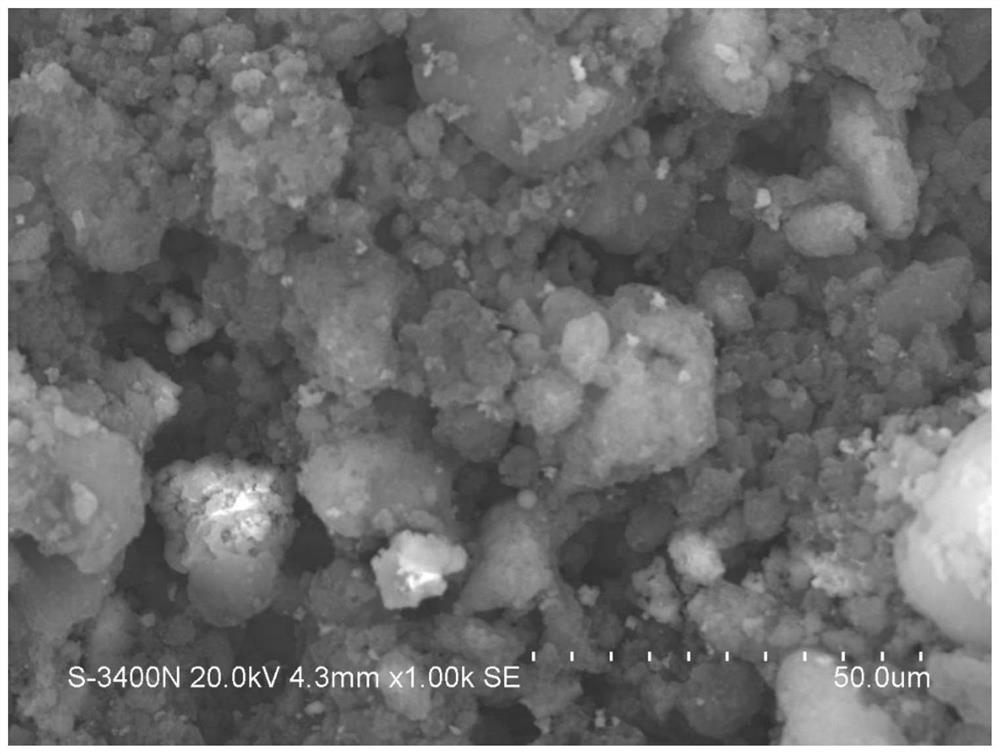

Embodiment 2

[0065] Step 1. Prepare Tourmaline Mixture

[0066] Add tourmaline powder, silicon dioxide powder, and surfactant (CTAB: cetyltrimethylammonium bromide) into a mixed solvent (volume ratio of water and absolute ethanol: 4:1), and ultrasonically for 10 minutes. ;

[0067] Among them, the particle size D50 of tourmaline powder is 0.1 μm to 10 μm, and the solid content is 1%; the particle size D50 of silicon dioxide powder is 10 μm to 20 μm, and the solid content is 1%; the mass ratio of tourmaline powder to silicon dioxide powder The ratio is 1:1; the mass of the surfactant accounts for 1% of the total mass of the tourmaline mixture.

[0068] Step 2. Prepare Tourmaline Hybrid Coating

[0069] Spray the tourmaline mixture prepared in step 1 on a glass plate, and place it in an oven to dry.

[0070] Among them, the spraying adopts the model YZ-K5 blue light atomizing gun, and the spraying area is 150cm 2 (containing 0.05g of tourmaline mixture), the drying temperature is 70°C, a...

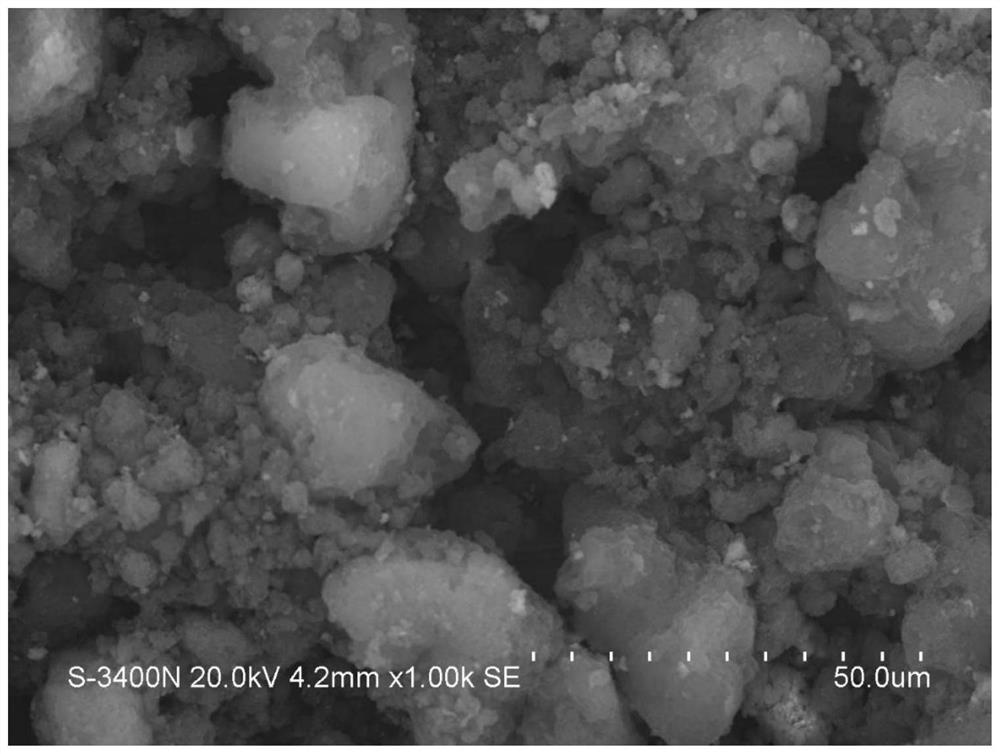

Embodiment 3

[0072] Step 1. Prepare Tourmaline Mixture

[0073] Add tourmaline powder, silicon dioxide powder, and surfactant (CTAB: cetyltrimethylammonium bromide) into a mixed solvent (volume ratio of water and absolute ethanol: 4:1), and ultrasonically for 10 minutes. ;

[0074] Among them, the tourmaline powder particle size D50 is 10 μm to 20 μm, and the solid content is 2%; the silicon dioxide powder particle size D50 is 20 μm to 30 μm, and the solid content is 1%; the mass ratio of tourmaline powder to silicon dioxide powder is 3:1; the mass of the surfactant accounts for 1% of the total mass of the tourmaline mixture.

[0075] Step 2. Prepare Tourmaline Hybrid Coating

[0076] Spray the tourmaline mixture prepared in step 1 on a glass plate, and place it in an oven to dry.

[0077] Among them, the spraying adopts the model YZ-K5 blue light atomizing gun, and the spraying area is 150cm 2 (containing 0.05g of tourmaline mixture), the drying temperature is 70°C, and the drying tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com