Power transmission line ice melting robot

A technology for power transmission lines and robots, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of high cost of DC ice melting devices, lack of effective deicing means, and high risk of manual deicing, so as to avoid high-risk The effect of working, reducing work intensity and improving equipment level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

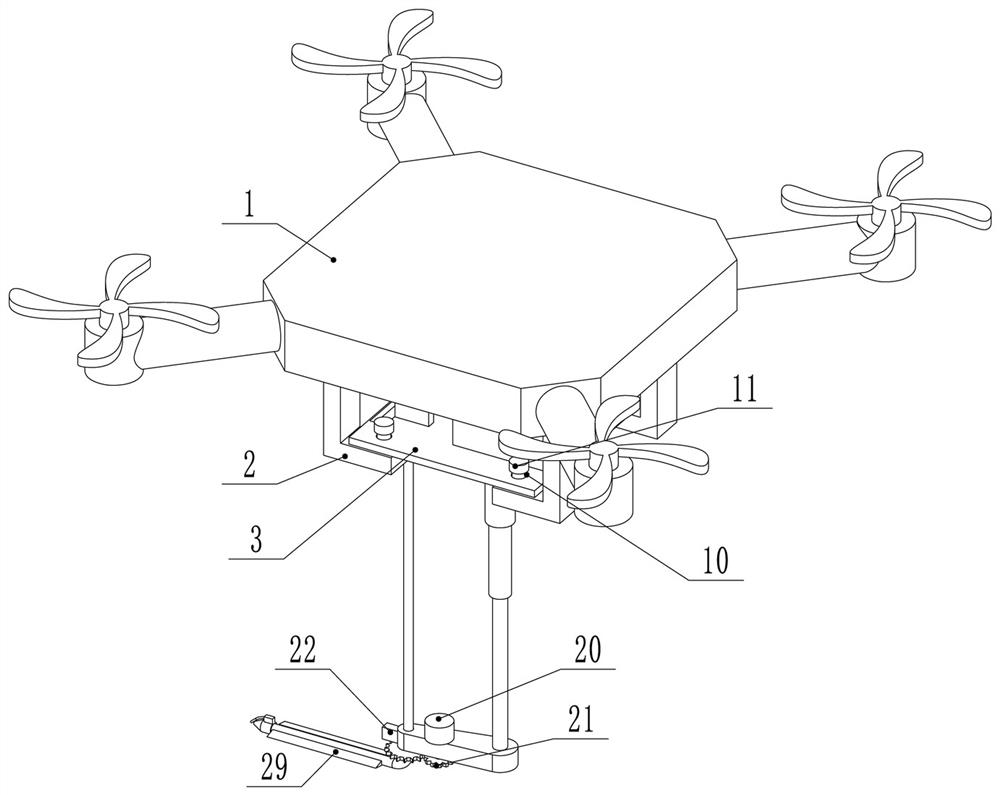

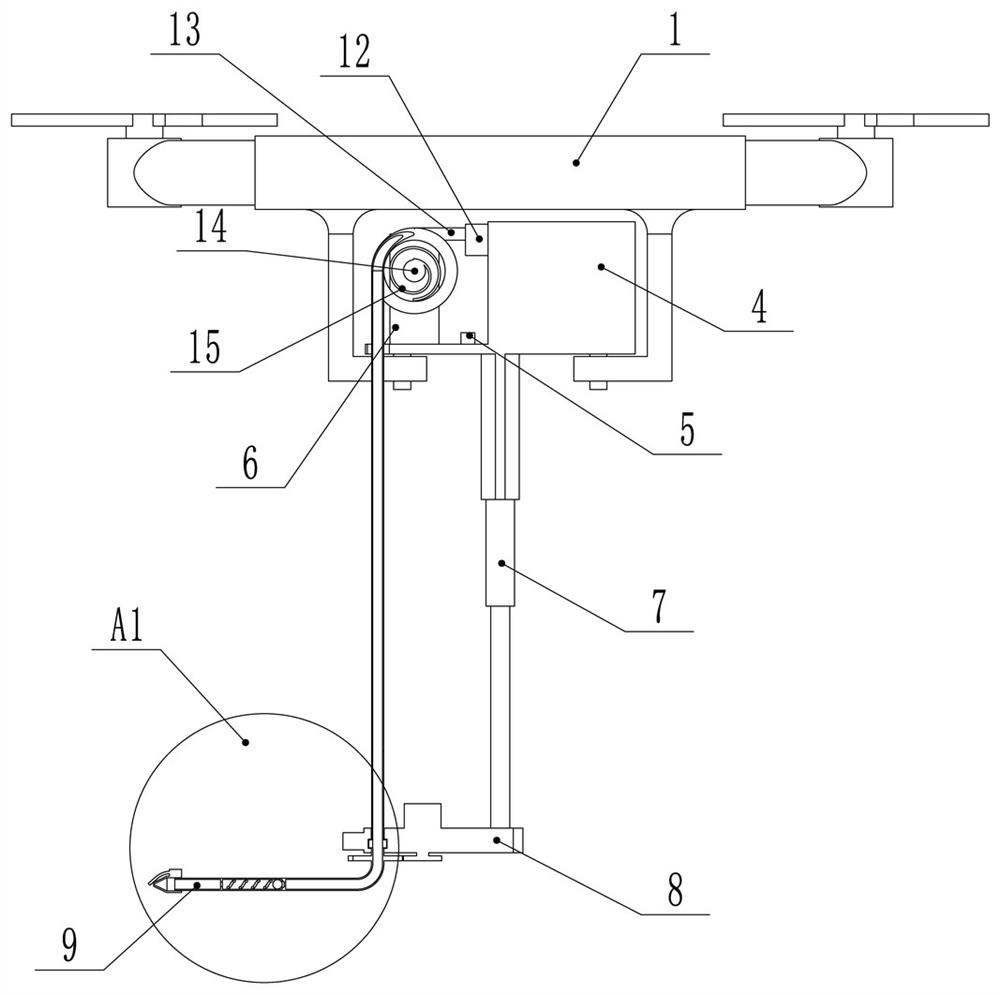

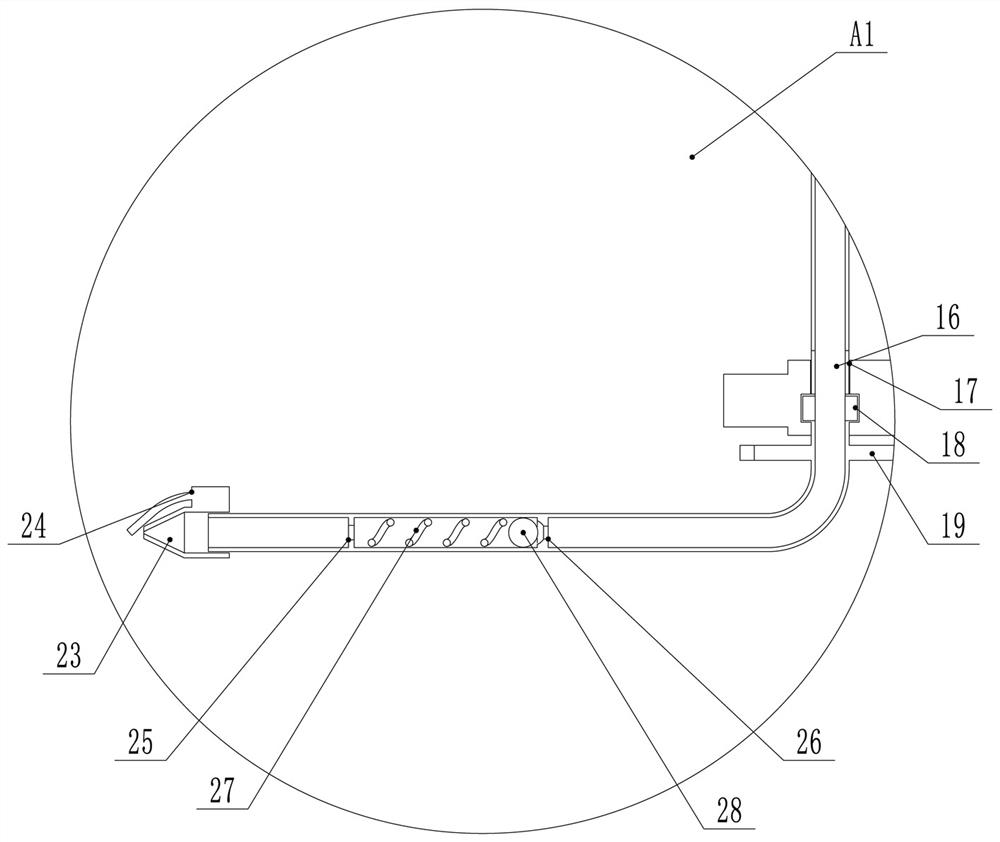

[0023] Embodiment 1, a transmission line ice-melting robot, when in use, by operating the unmanned body 1, so that the whole body reaches the top of the icing line, and then the electric push rod 7 works to make the fixed plate 8 reach the freezing point. Near the ice line, the motor 20 works, and then the angle of the L-shaped hard pipe 16 can be adjusted under the transmission of gear one 19 and gear two 21, so that the nozzle 23 is opposite to the icing line, and then the oil well pump 12 and the igniter 24 works, the oil pump 12 works so that the fuel is sprayed from the position of the nozzle 23, and the igniter 24 works to ignite the sprayed fuel, thereby performing the ice-melting deicing operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com