Aqueous white electroconductive primer coating composition and method for forming multilayer coating film using same

A technology of conductivity and composition, applied in conductive paints, coatings, primers, etc., can solve the problems of difficulty and high resistance, and achieve the effect of reducing paint waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

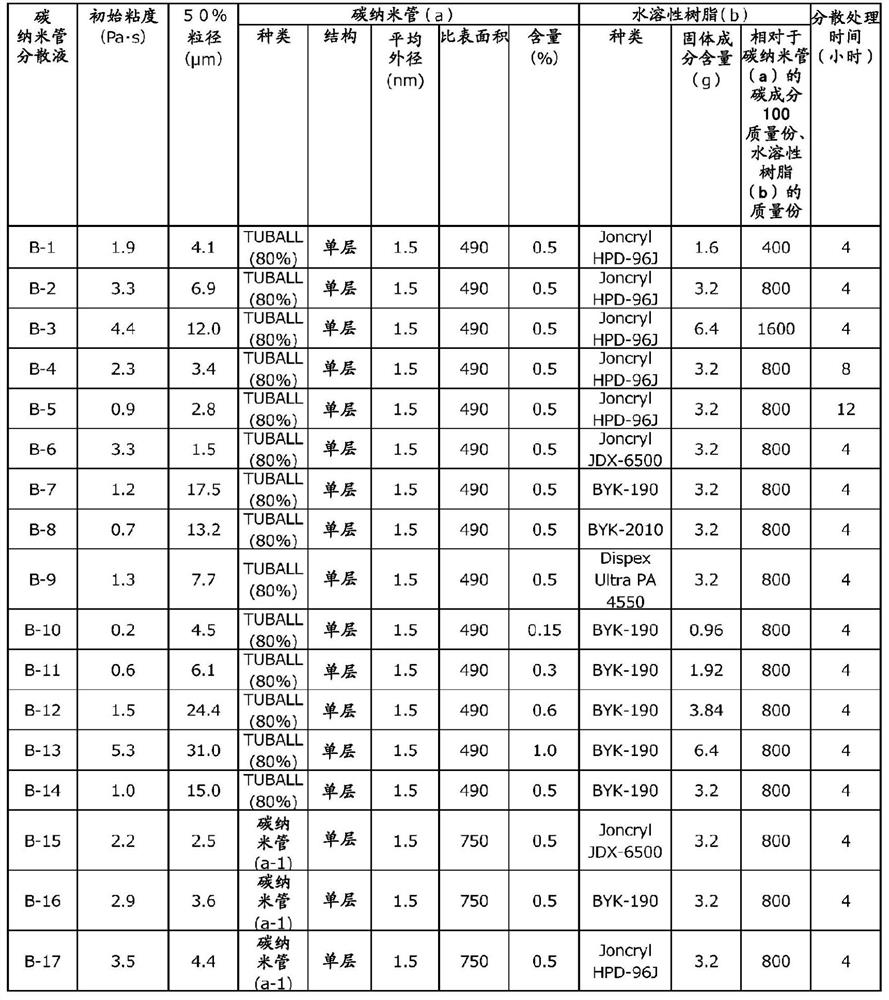

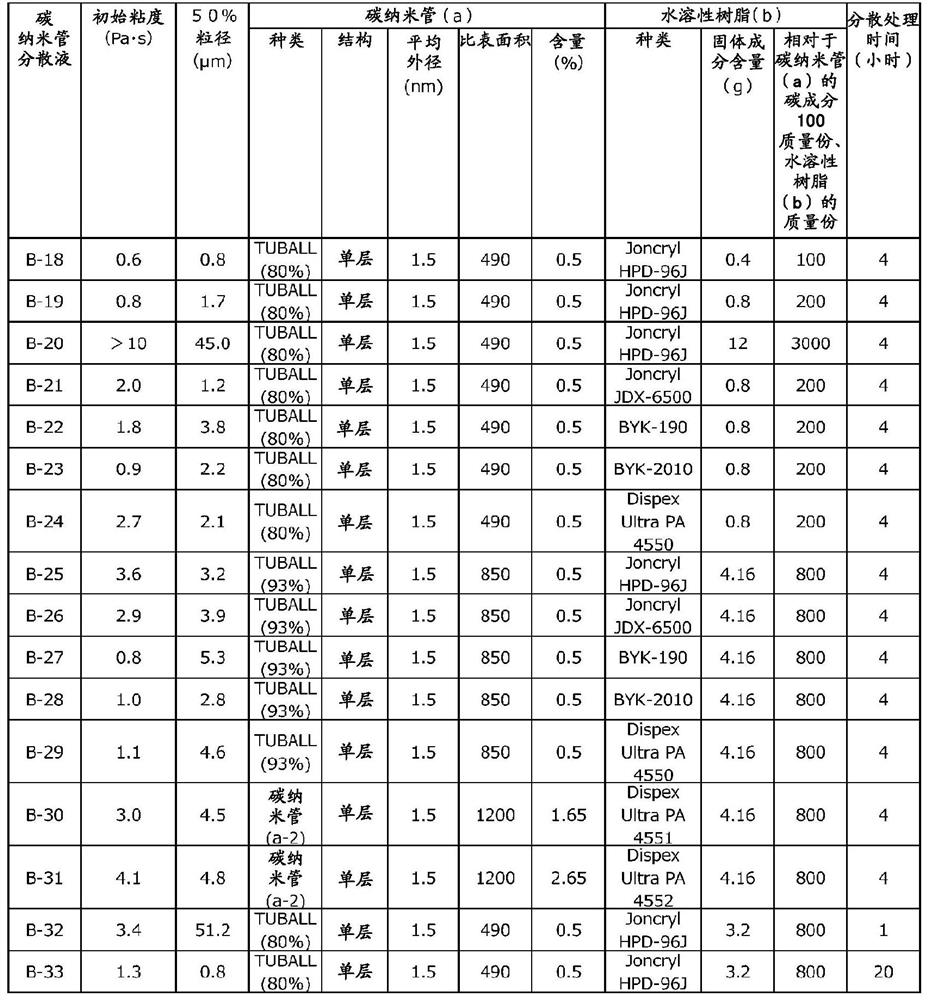

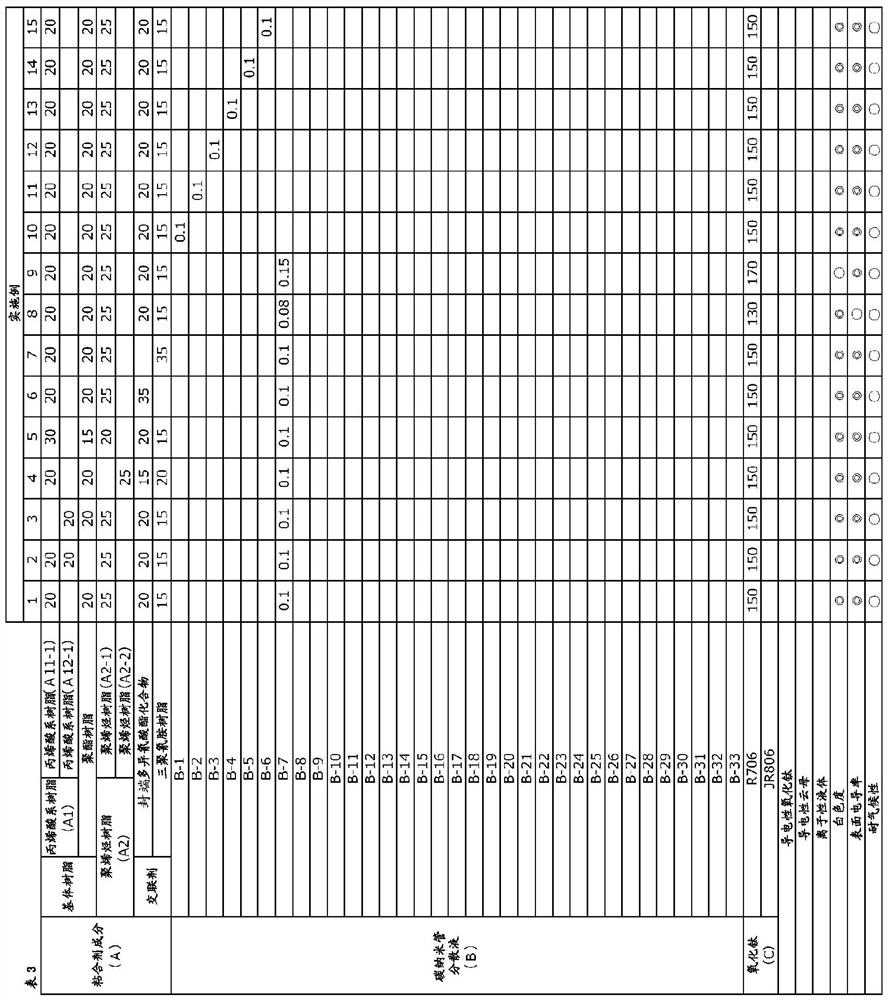

[0211] Hereinafter, the present invention will be described more specifically with reference to production examples, examples, and comparative examples. However, the present invention is not limited by these. In each example, "parts" and "%" are based on mass unless otherwise specified. In addition, the film thickness of a coating film is based on a cured coating film.

[0212]

[0213]

[0214]

[0215] Add 40 parts of ethylene glycol monobutyl ether and 30 parts of isobutanol into a reaction tank equipped with a stirrer, thermometer, reflux cooler, etc., heat and stir, and after reaching 100°C, mix the following monomers for 3 hours Add dropwise.

[0216] Styrene 10 parts

[0217] Methyl methacrylate 18 parts

[0218] 35 parts of isobornyl acrylate

[0219] 10 parts n-butyl acrylate

[0220] 20 parts of 2-hydroxyethyl methacrylate

[0221] Acrylic 7 parts

[0222] 1 part of 2,2′-azobisisobutyronitrile

[0223] 5 parts isobutanol

[0224] After the dropwise ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com