Method and apparatus for locally removing and/or modifying polymer material on surface

A polymer material, local technology, applied in the process of producing decorative surface effects, opto-mechanical equipment, photosensitive material processing, etc., can solve the problem that precise local heating cannot be achieved, and achieve the effect of improving the bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

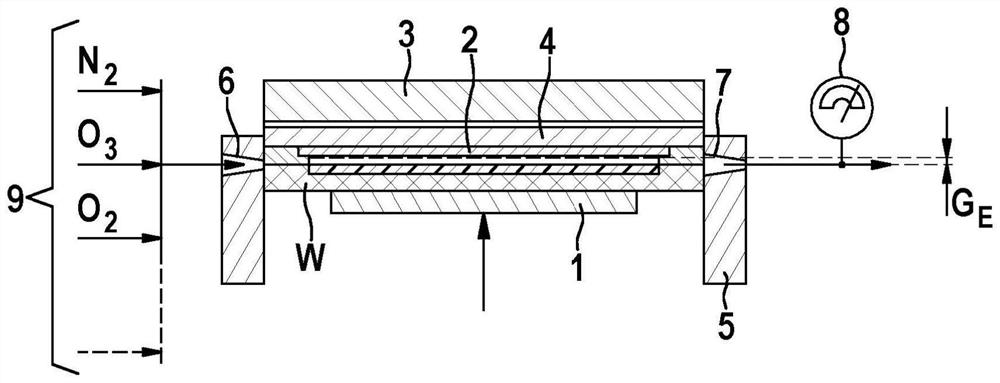

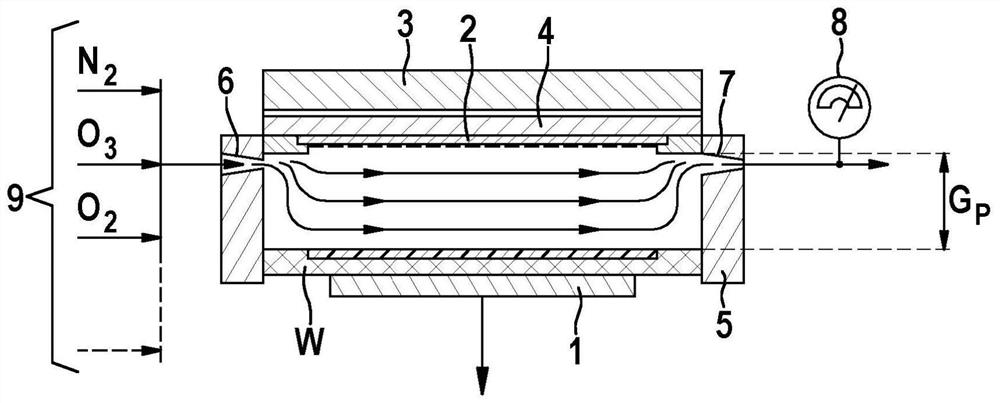

[0027] Figure 1a and Figure 1b A device according to the invention for locally removing and / or modifying polymer material on the surface of a wafer is shown. The apparatus has an adjustable wafer stage 1 , a mask 2 , a VUV light source 3 , a sealed reaction chamber 5 , a gas inlet 6 , a gas outlet 7 and a gas flow controller 8 . The light source is here a VUV excimer module which is arranged at a distance 4 from the mask 2 . The intermediate space created by the distance 4 can be filled with nitrogen N 2 or another VUV-permeable inert gas. On the opposite side of the mask 2 a wafer W can be arranged on an adjustable wafer table 1 . The wafer W has a polymer coating P on the surface OW opposite the mask 2 .

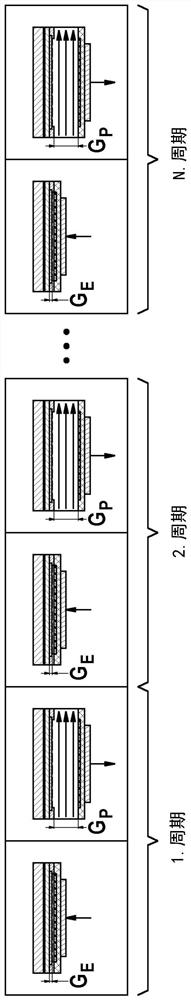

[0028] Figure 1a The device is shown during a first operating state, ie during exposure. For the exposure, the wafer stage 1 is adjusted with an exposure gap GE (English: gap exposure) between the wafer W and the mask 2 . The intermediate space created by the expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com