Dry-method aggregate pre-separation system and building type sand making process system

A pre-sorting and aggregate technology, applied in grain processing and other directions, can solve the problems of ineffective selection of coarse sand, large amount of returned material, over-grinding, etc., to achieve simple structure, accurate crushing and returning materials, and reduce screening. effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

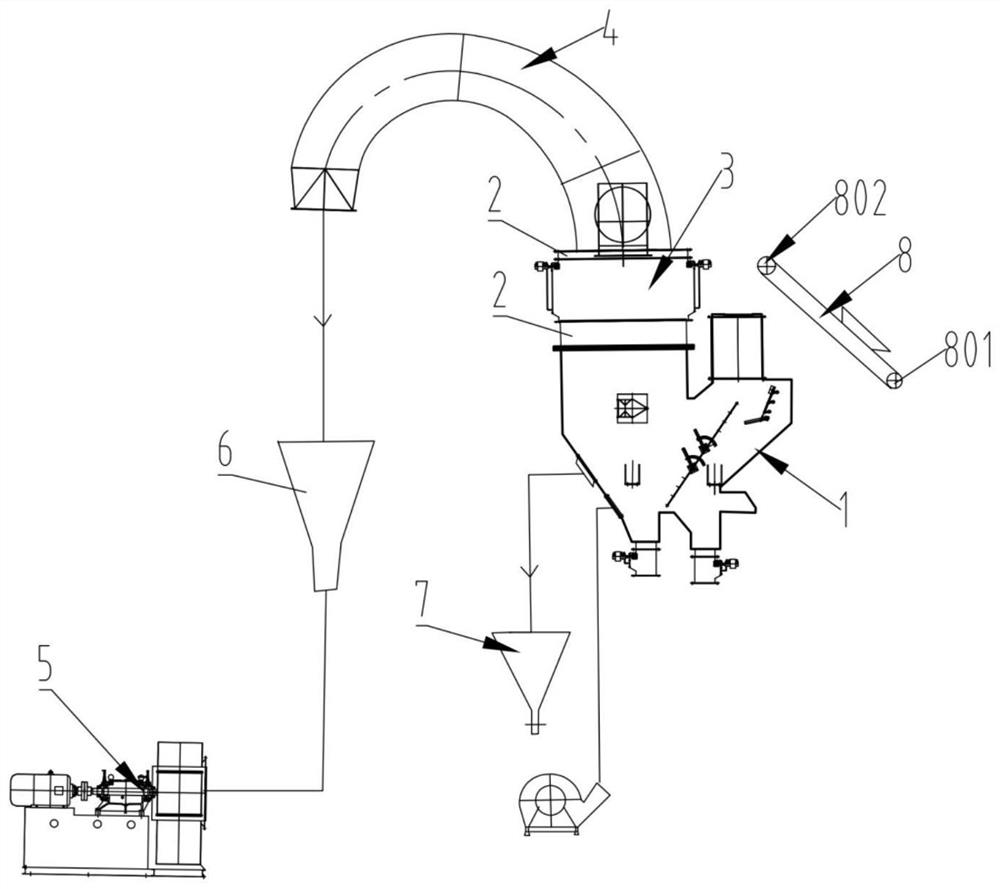

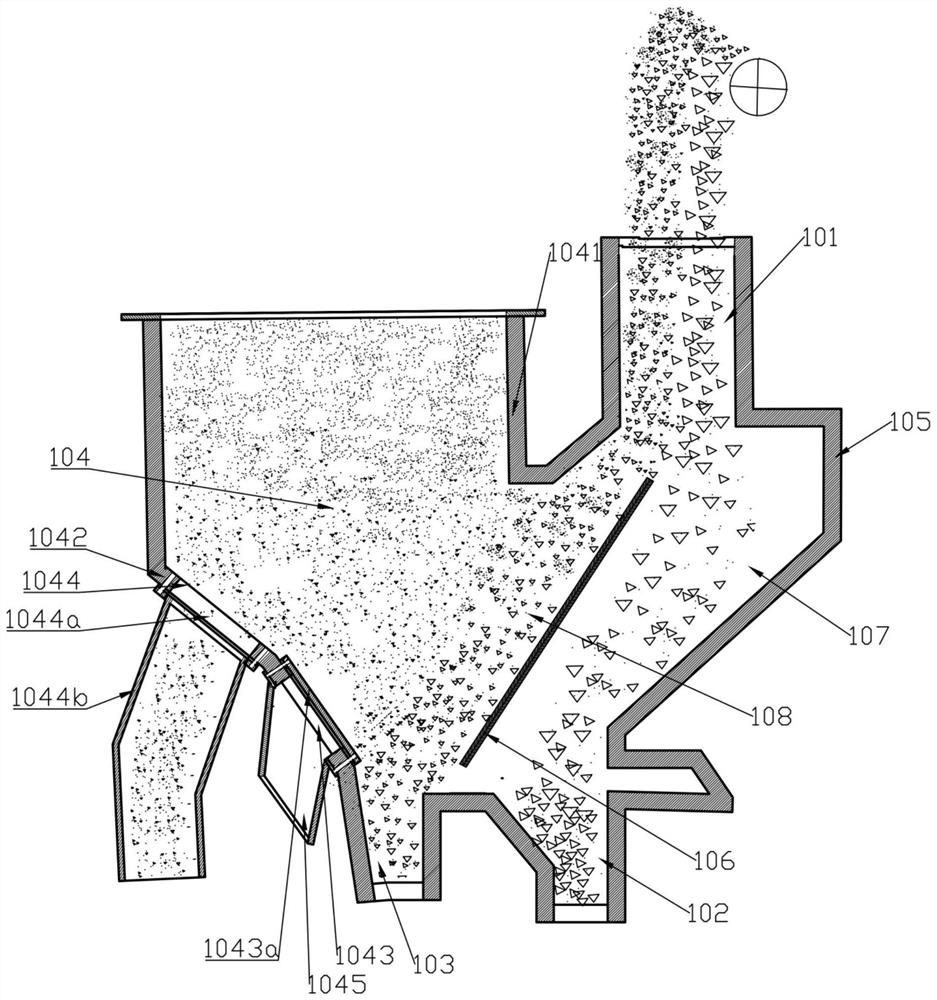

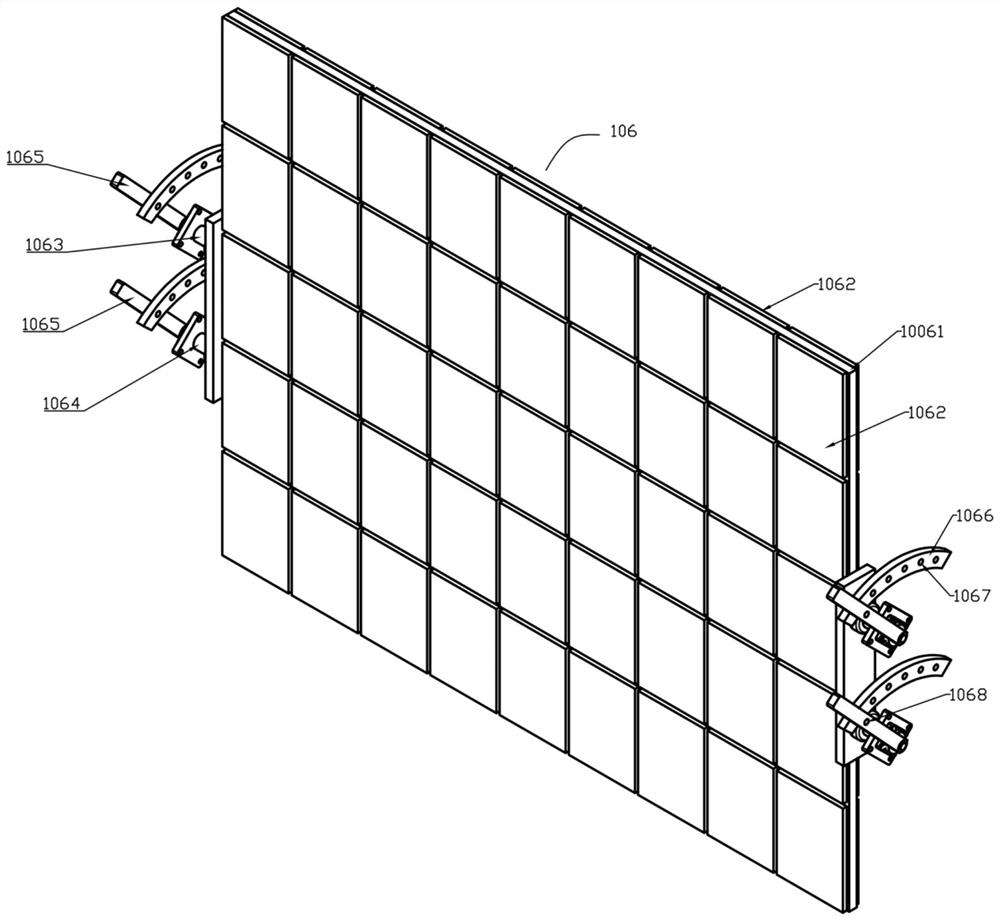

[0050] Such as figure 1 , figure 2And other views, the dry aggregate sorting system includes a non-powered powder separator 1, which is a "pants" structure, including an aggregate inlet 101 connected to the feeding system, two types The "trouser legs" are the coarse sand separation area 107 and the medium and fine sand separation area 108 respectively, and the sand outlet flap valve 106 for regional adjustment is set between the coarse sand separation area 107 and the medium and fine sand separation area 108. The coarse sand sorting area 107 is connected to the coarse sand outlet 102 , and the medium and fine sand sorting area 108 is connected to the medium and fine sand outlet 103 .

[0051] Such as figure 1 As shown, the non-powered powder separator 1 also includes a stone powder discharge port, the stone powder discharge port is connected to the first stone powder discharge channel 104, and the first stone powder discharge channel 104 is sealed and connected to the ultra...

no. 2 example

[0063] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , based on the dry aggregate sorting system provided in the first embodiment of the present application, the second embodiment of the present application proposes a floor-type sand making process system. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0064] Such as Figure 7 with Figure 8As shown, this embodiment includes a building body in the form of an all-steel structure, including a main building body 9 and an auxiliary building body 10 respectively. The main building body 9 is divided into six floors, and the sixth floor on the highest floor has a lighter installation load as in the first embodiment. The first stage dry aggregate sorting system a described in the example, the second stage dry aggregate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com