Gas turbine flue gas curing concrete heat storage material carbon sequestration system and method

A heat storage material and concrete technology, applied in chemical instruments and methods, unloading devices, ceramic molding machines, etc., can solve the problem of high carbon sequestration costs, achieve low heat storage costs, stable physical properties of the device, and easy on-site installation and pouring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

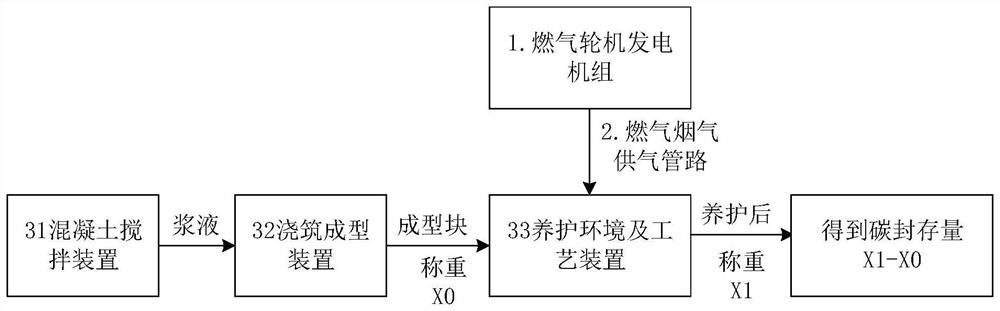

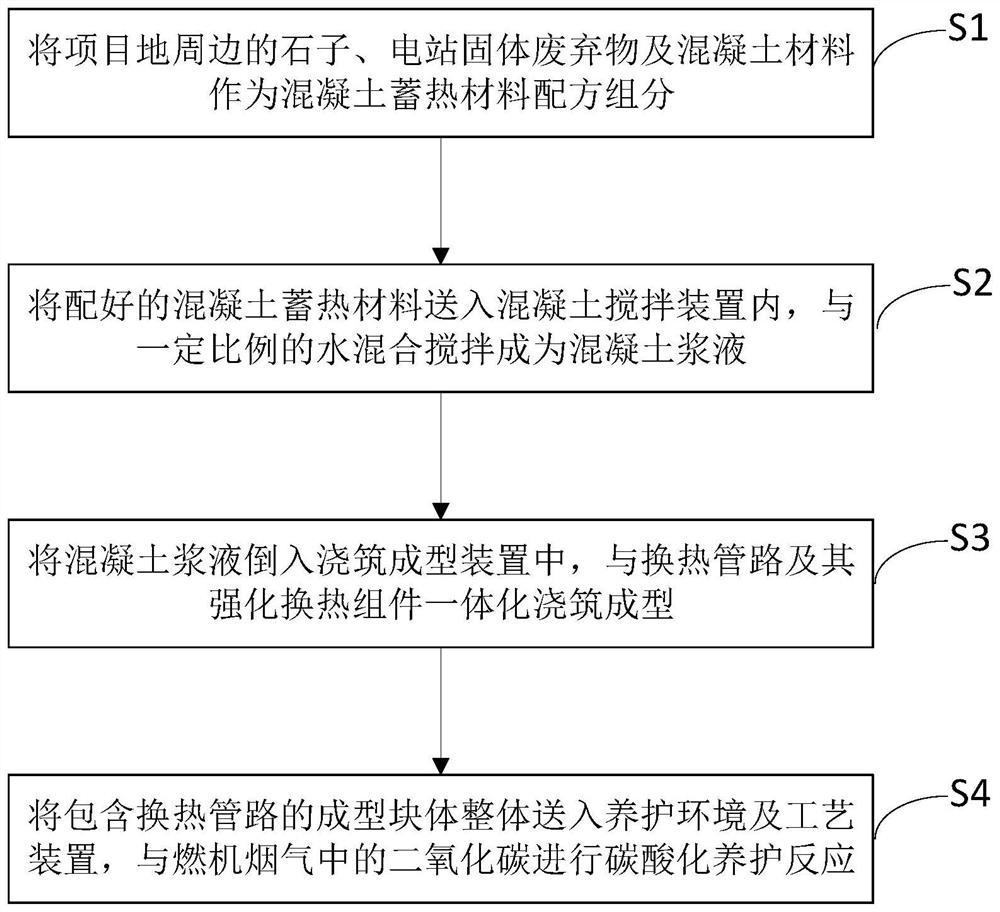

[0035] Such as figure 1 As shown, the first aspect of the present invention provides a gas turbine flue gas curing concrete heat storage material carbon sequestration system, including a gas turbine generator set 1, a gas flue gas supply pipeline 2, and a concrete heat storage material curing unit;

[0036] The concrete heat storage material maintenance unit includes a concrete mixing device 31, a pouring molding device 32, and a maintenance environment and process device 33; the concrete mixing device 31 is used to send the stirred concrete slurry into the pouring molding device 32 to generate a molding block; The maintenance environment and process device 33 is used to communicate with the flue gas discharge side of the gas turbine generator set 1 through the gas flue gas supply pipeline 2, so that the carbonation curing reaction of the formed block occurs in the maintenance environment and process device 33 to realize carbon sequestration.

[0037] As an example of an embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com