Air pressure low carbon packaging method, packaging box and plate

A packaging method and packaging box technology are applied in the field of low-carbon and environmentally-friendly packaging, which can solve the problems of carbon dioxide emission, energy waste, pollution, etc., and achieve the effect of promoting low-carbon and environmental protection and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

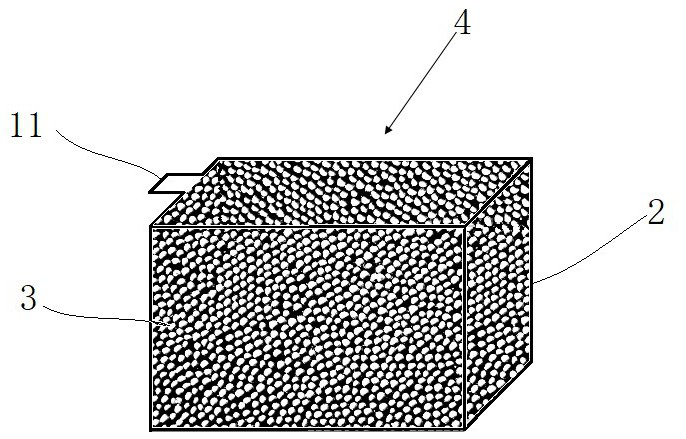

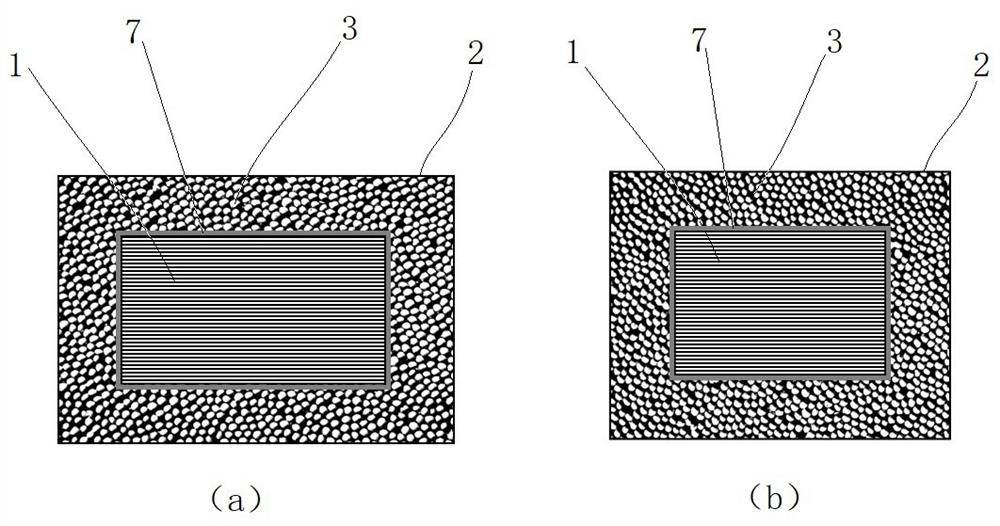

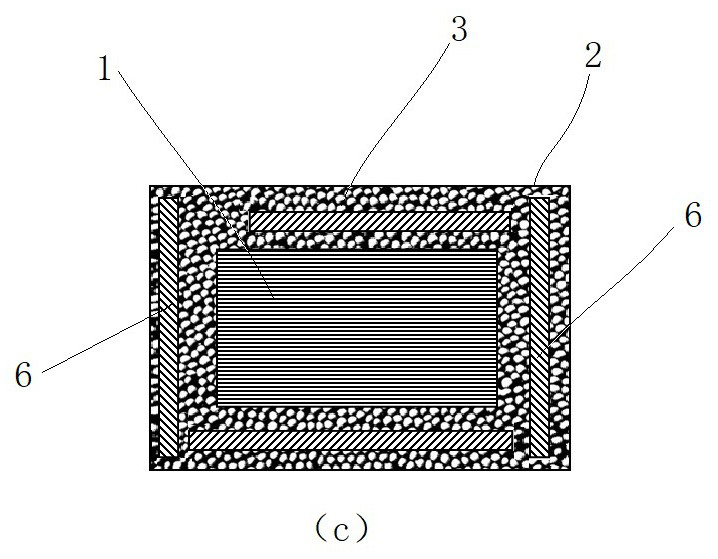

[0093] like figure 1 , figure 2 , image 3 as shown, figure 1 It is a schematic diagram of the shape of an air-compressed low-carbon packaging product. figure 2 for figure 1 A schematic diagram of the structure of a transverse section (a) and a longitudinal section (b) in . image 3 for figure 1 A schematic diagram of the structure in a transverse section (c).

[0094] A rectangular product 1 was originally planned to be packaged in an existing carton (hereinafter referred to as the original carton), but now it can be replaced with an air-compressed low-carbon packaging method of the present application.

[0095] S1. Select a 40 μm thick PA / PE composite film to make a bag 2 that is airtight and equivalent to the size of the original carton.

[0096] S2. Put the bag 2 into a molding mold with a preset shape like an original carton, and put a loose filler 3 into the bag; for example, hard foam particles or perlite particles with a rough surface with a diameter of about ...

Embodiment 2

[0109] like Figure 4 , Figure 5 as shown, Figure 4 It is a schematic diagram of the shape of an air-compressed low-carbon packaging product. Figure 5 for Figure 4 A schematic diagram of a longitudinal cross-sectional structure in .

[0110] A product 1 with six bottles of wine in one box was originally planned to be packaged in an existing carton (hereinafter referred to as the original carton), but now it can be replaced with the following air-compressed low-carbon packaging method of this application.

[0111] S1. Select a 40 μm thick PA / PE composite film to make a bag 2 that is airtight and equivalent to the size of the original carton.

[0112] S2. Put the bag 2 into the forming mold whose preset shape is the shape of the original carton, and put a kind of loose filler 3 into the bag; for example, wood chips with a diameter of about 2mm.

[0113] S3. Use a rice brick vacuum packaging machine to pump the inside of the bag to a predetermined vacuum degree.

[0114...

Embodiment 3

[0121] like Image 6 , Figure 7 , Figure 8 as shown, Image 6 It is a schematic diagram of the shape of an air-compressed low-carbon packaging box. Figure 7 for Image 6 A schematic diagram of the appearance of a covered air-pressure low-carbon packaging box, Figure 8 for Figure 7 Schematic diagram of the cross-sectional structure at position A-B.

[0122] A product 1, which was originally planned to be packed in an existing carton (hereinafter referred to as the original carton), can now be replaced with an air-compressed low-carbon packing box of the application as follows.

[0123] S1. Select a 40 μm thick PA / PE composite film to make an airtight bag 2 shaped like a manger after being inflated.

[0124] S2. A kind of loose filler 3 is housed in the bag.

[0125] S3. The inside of the bag is pumped to a predetermined vacuum degree.

[0126] S4. The mouth of the bag 11 is sealed, and the inside of the bag is a vacuum. The bag 2 and its filler 3 are formed under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com