System for guaranteeing smoke ultra-clean emission through boiler ventilation air methane

An emission system and ultra-clean technology, applied in the direction of indirect carbon dioxide emission reduction, combustion methods, and controlled combustion, can solve the problems of long construction period, large water consumption, and large floor area, so as to promote low-carbon harmonious development, The effect of reducing environmental pollution and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

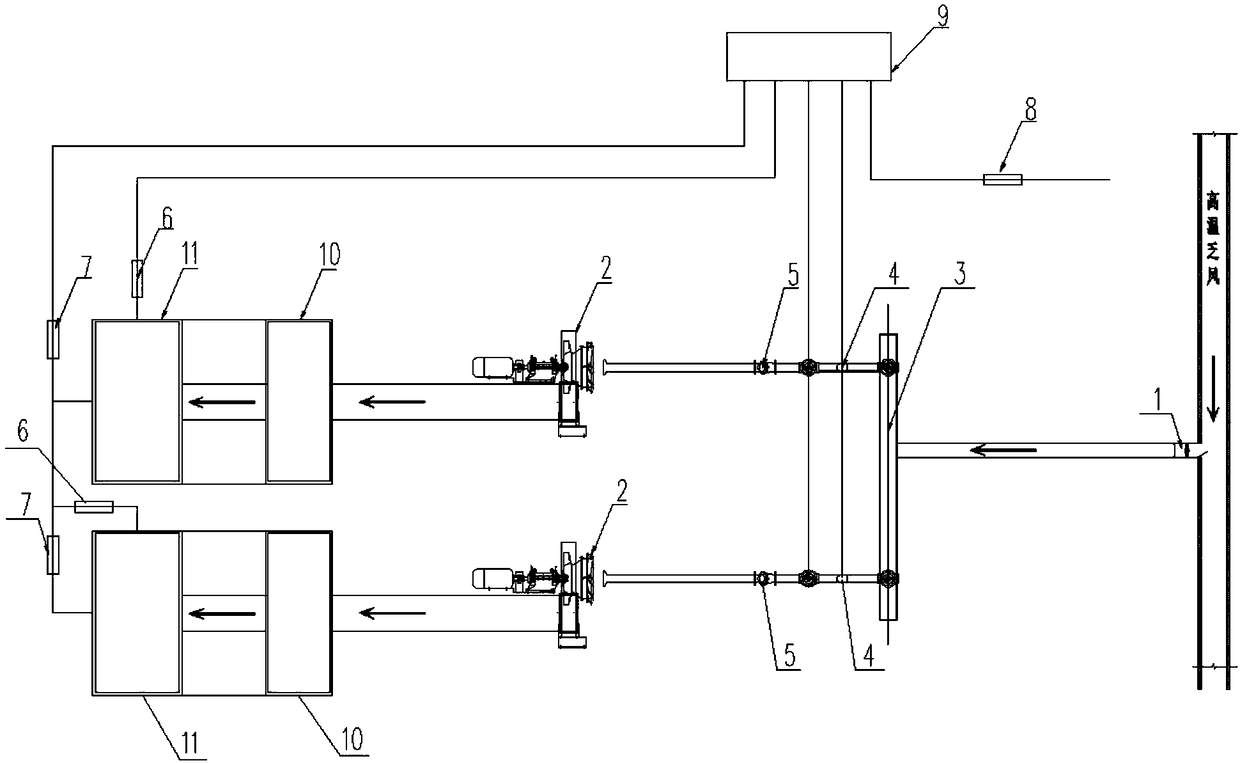

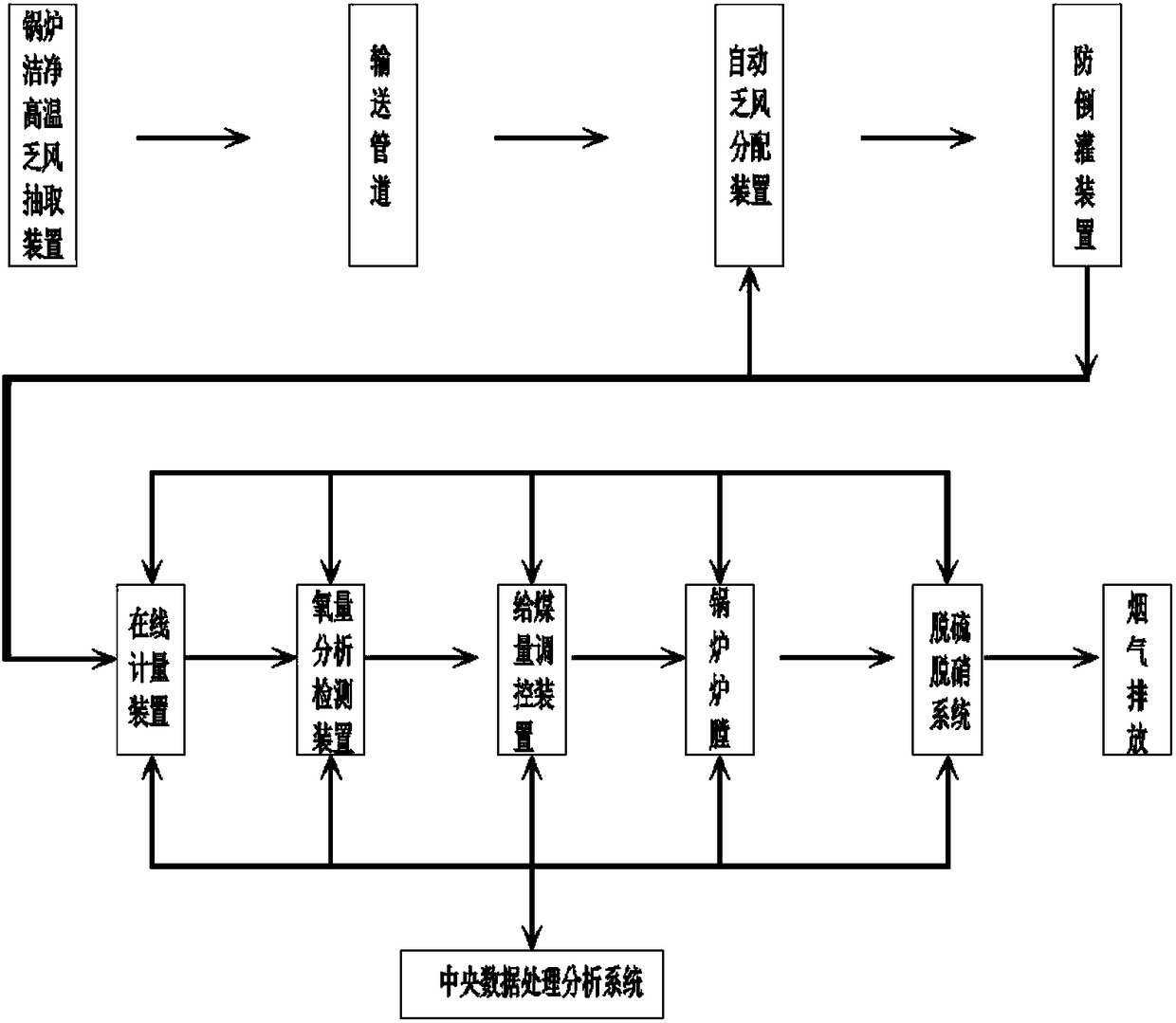

[0021] Such as figure 1 As shown, in this embodiment, a system using boiler exhaust air to ensure ultra-clean discharge of flue gas includes exhaust air extraction device 1, automatic exhaust air distribution device 3, two primary fans 2, two anti-backflow devices 5, two An on-line metering device 4, two oxygen monitoring and analysis devices 6, two coal volume control devices 7, an on-line monitoring device for sulfur and nitrogen pollutants 8 and a central data analysis and processing system 9, the air inlet of the exhaust air extraction device 1 is connected to the The tail of the flue is connected to extract high-temperature exhaust air. The air outlet of the exhaust air extraction device 1 is connected to the air inlet of the automatic exhaust air distribution device 3 through the conveying pipe, and the two air outlets of the automatic exhaust air distribution device 3 are respectively connected to the two air outlets through the conveying pipe. The air inlets of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com