High-temperature tertiary air coal gasification and reburning high-efficiency denitrification system for cement decomposition furnace

A cement decomposition furnace and coal gasification technology, which is applied in the direction of granular/powdered fuel gasification, separation methods, gas treatment, etc., can solve the problems of poor denitrification effect, and achieve the goals of avoiding secondary pollution, reducing consumption, and reducing ammonia escape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

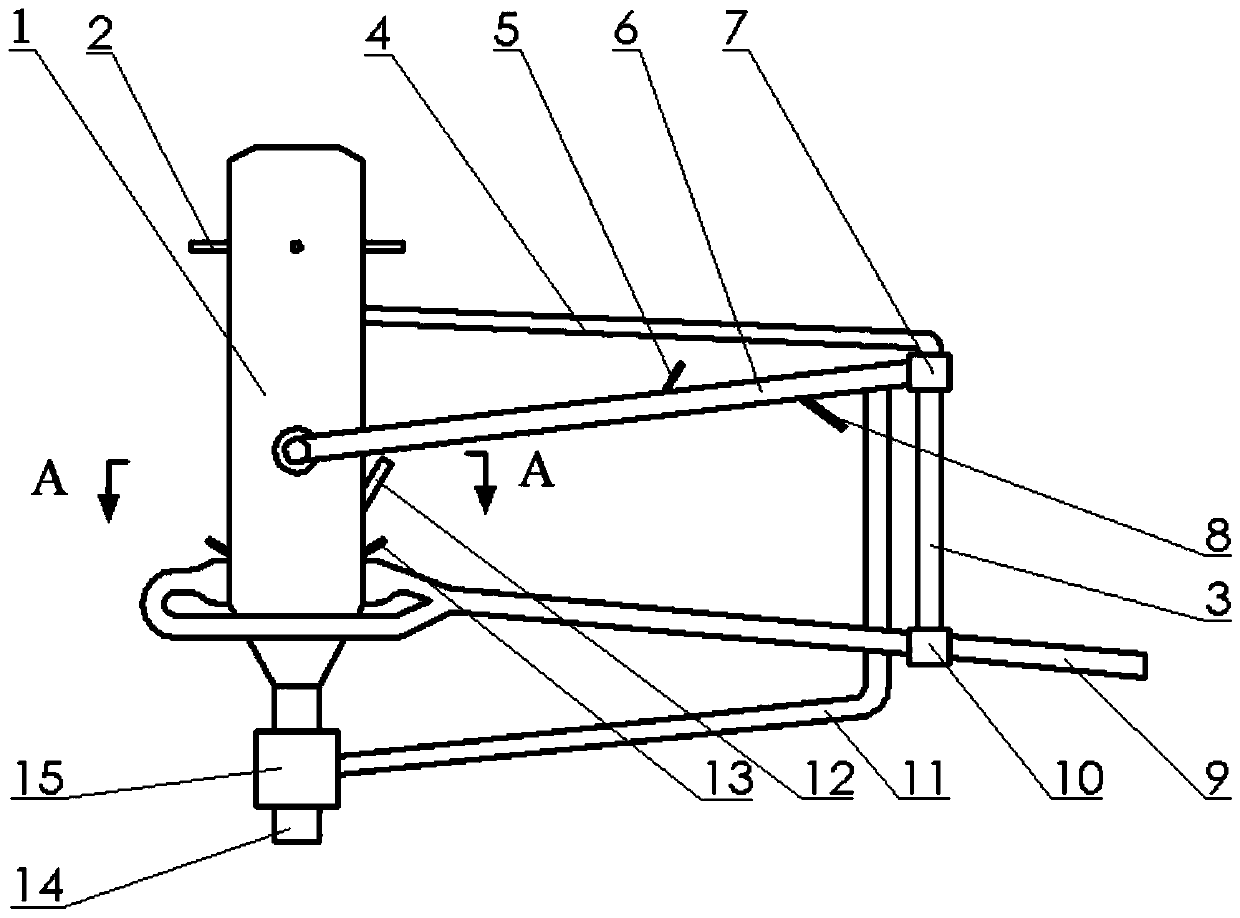

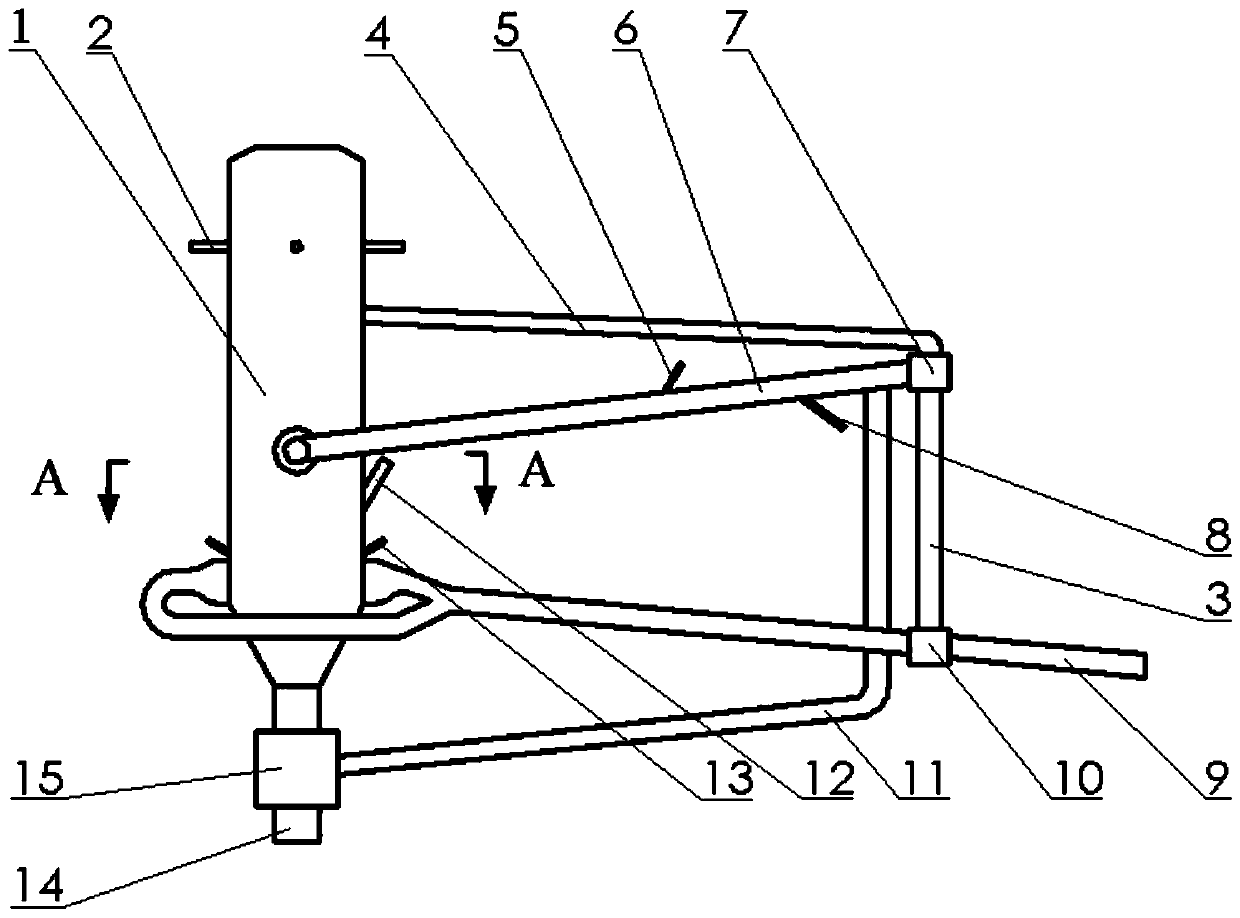

[0023] Such as figure 1 , 2 As shown, the denitrification system according to one embodiment of the present invention generally includes a decomposition furnace 1 and a high-temperature tertiary air pipe 9 .

[0024] The calciner 1 is connected with the coal injection pipe 13 of the main combustion area, and the raw meal feeding pipe 12 of the lower raw meal; ℃), release heat to decompose the raw meal.

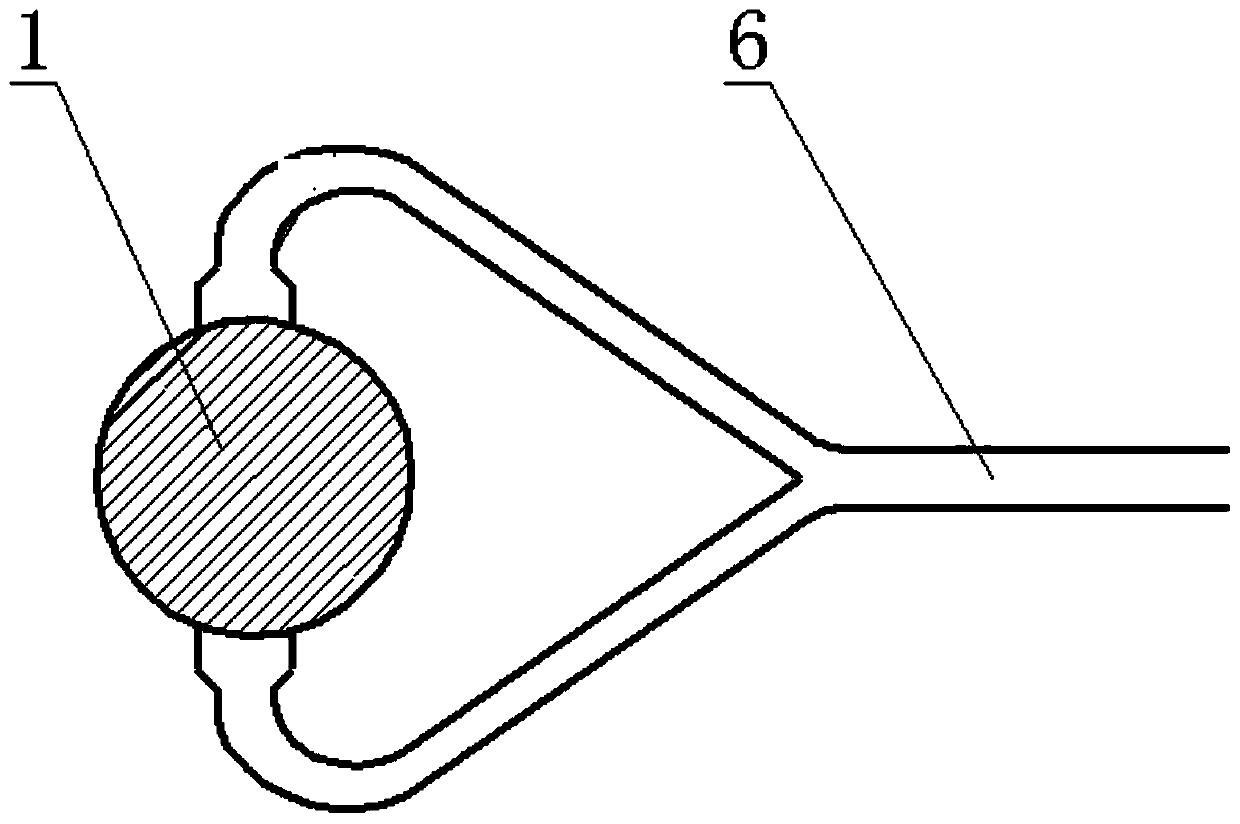

[0025] The high-temperature tertiary air pipe 9 communicates with the main combustion zone of the calciner 1 to provide combustion-supporting high-temperature air (900-1100° C.) for pulverized coal combustion. It is used to divert the high-temperature air in the high-temperature tertiary air pipe 9, and the unconnected end of the branch pipe 3 respectively leads to the coal gasification pipe 6 and the burn-out air pipe 4 connected with the reburning zone and the burnout zone of the calciner 1, and connects the high-temperature tertiary air pipe 4 between the branch pipe 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com