Method for removing nitrobenzene in water

A nitrobenzene, solution technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as reduced degradation efficiency, reduced reactivity, and unfavorable macromolecular diffusion, and achieves improved removal rate, The effect of reducing the initial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for removing nitrobenzene in water, the concrete steps are as follows:

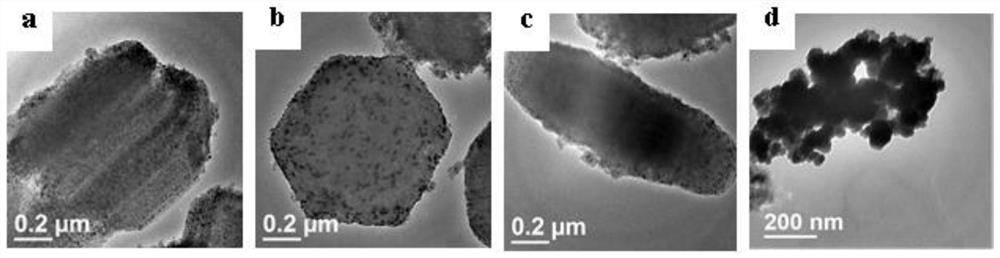

[0038] The first step, the preparation of unloaded nano zero-valent iron: Fe(NO 3 ) 3 9H 2 O into N 2 baked in a quartz tube; the heating rate was 1°C / min, the temperature was raised to 150°C, and after holding for 1h, the temperature was continued to be raised to 300°C for 4h; 2 Reduction, the unloaded NZVI can be obtained;

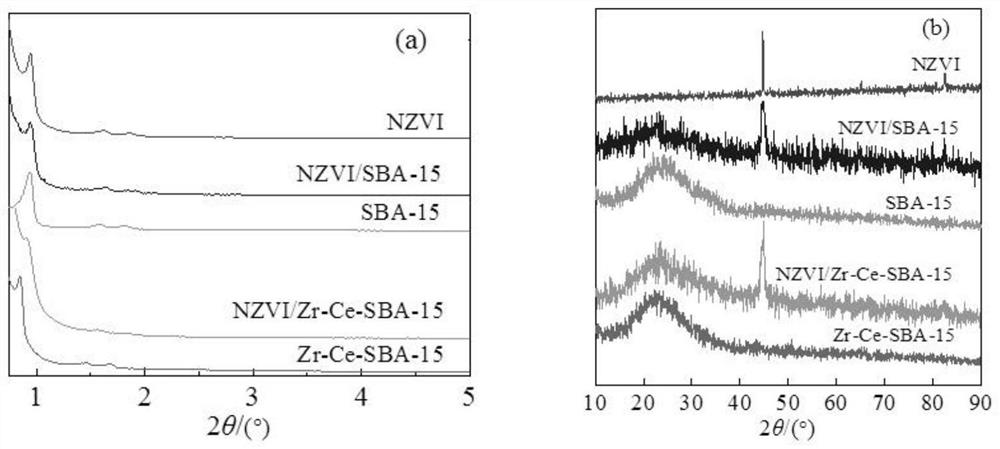

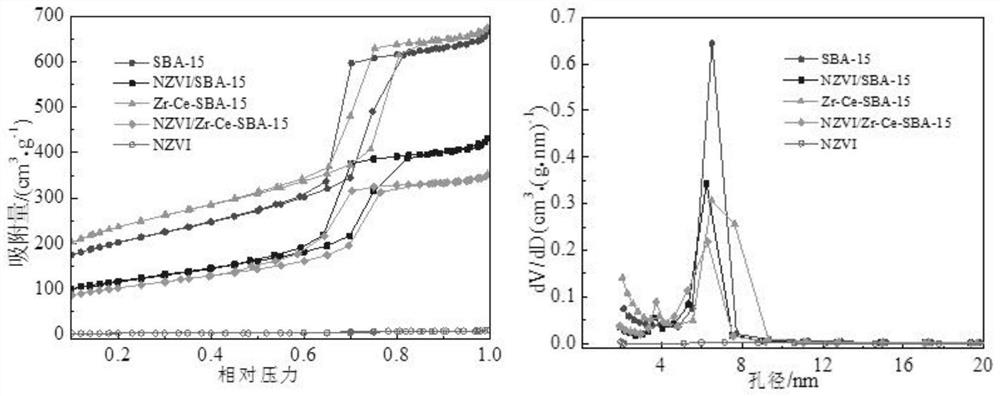

[0039] The second step is the synthesis of hexagonal short-channel Zr-Ce-SBA-15 and fibrous long-channel SBA-15 ordered mesoporous silicon materials: add template agent P123 to deionized water, and magnetically mix and stir at a constant temperature of 35°C Until P123 is completely dissolved; add 2mol / L HCl and ethyl orthosilicate to the above solution, and stir magnetically for 24 hours at 35°C, wherein the molar ratio of the raw materials used is about 1TEOS:0.017P123:5.88HCl:136H 2 O; move the stirred reaction solution into a high-pressure crystallization ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com