Induction heating system of rotary silicon carbide crystal growth furnace and crystal growth furnace

A technology of rotating silicon carbide and induction heating, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of the influence of the magnetic field distribution of the induction coil, the temperature field distribution in the furnace body, and the decrease of stability, etc., to achieve optimization. The effect of uniform magnetic field distribution, complex optimization structure, and low optimization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

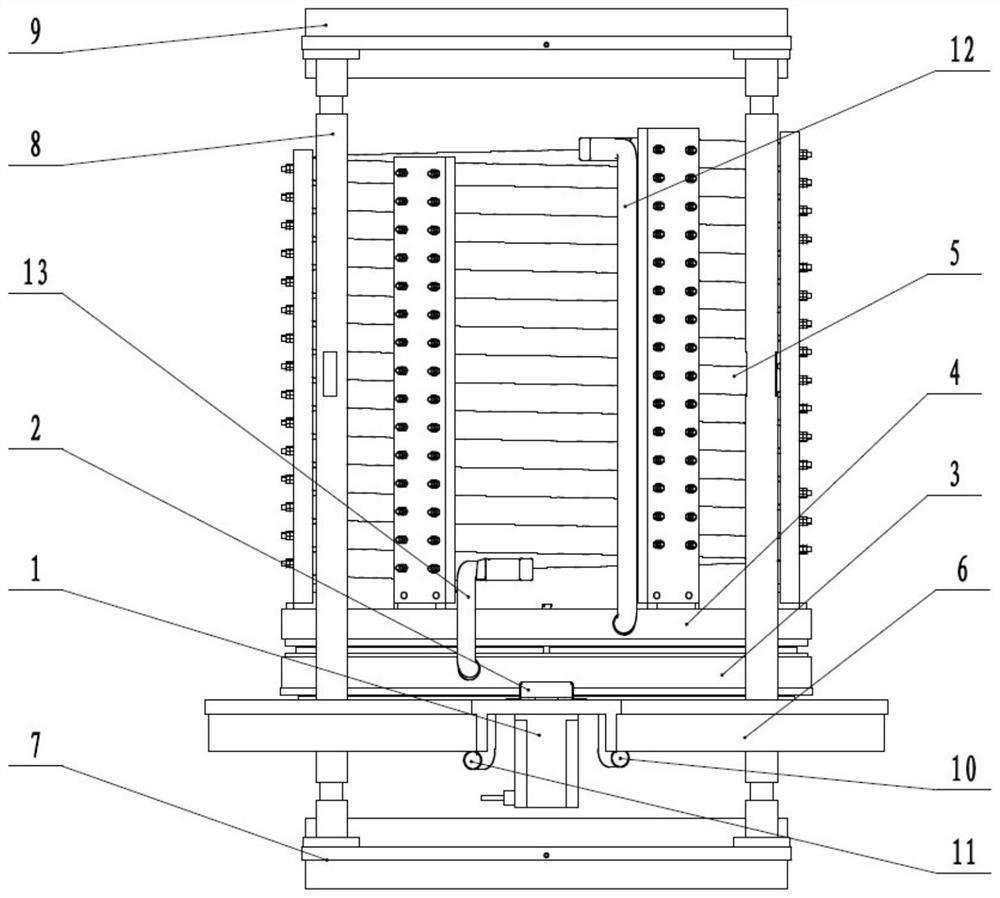

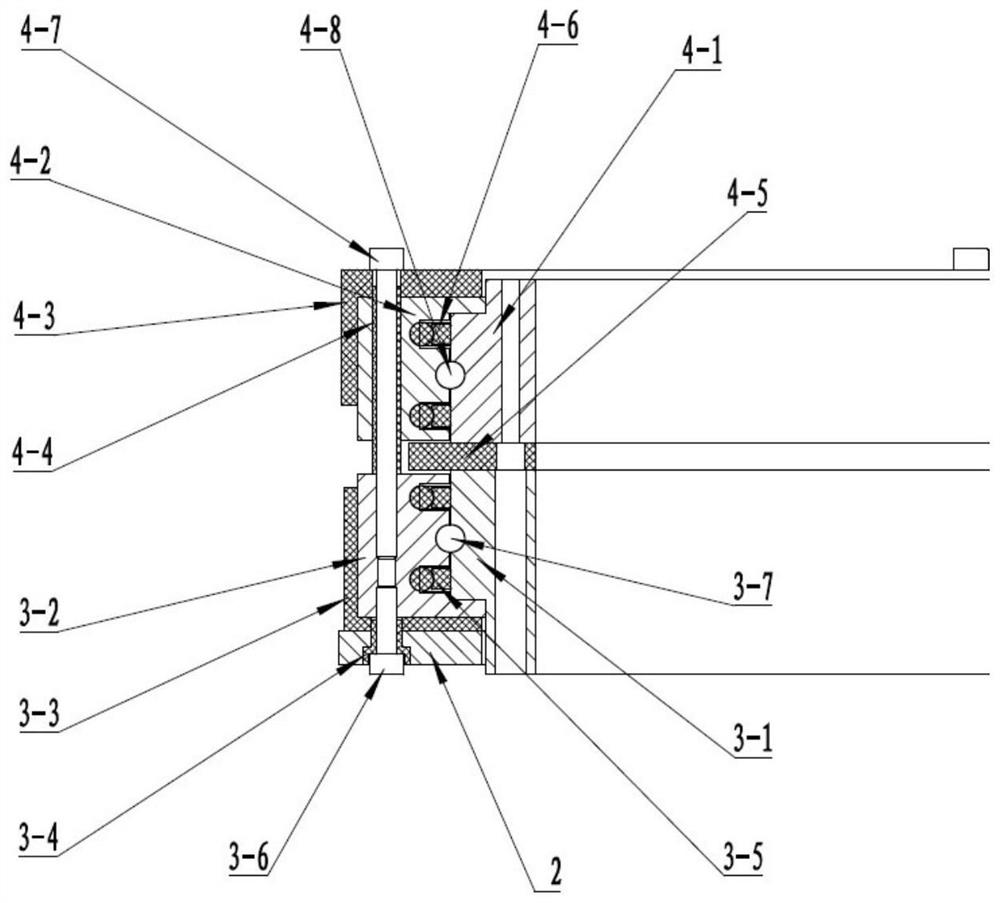

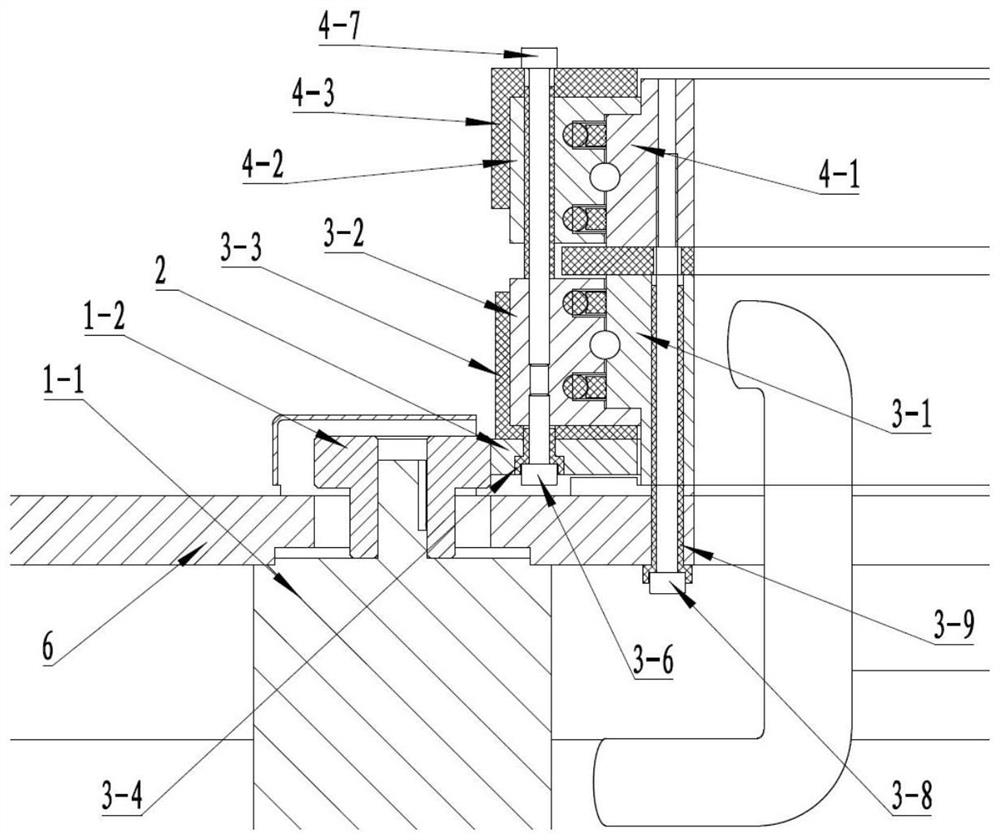

[0018] Please combine figure 1 As shown, the present invention provides a rotary silicon carbide growth furnace induction heating system. The present invention is a new design that can realize rotation control on the basis of realizing the induction furnace magnetic field up and down, optimizes the induction furnace magnetic field distribution, and optimizes the interior of the furnace body. The device for sensing temperature distribution optimizes the complex structure and poor stability caused by the rotation of the crucible, including: rotating power 1; transmission mechanism part; water-cooled conductive ring 3; water-cooled conductive ring 4; induction coil 5; coil mounting seat 6; lower flange 7; support column 8; upper flange 9; first bottom inlet water-cooling cable joint 10; second bottom inlet water-cooling cable joint 11; The water-cooled conductive ring 3 is used as a rotating fixed seat, and includes a water-cooled conductive ring inner ring 3-1 and a water-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com