Optical fiber temperature sensor

An optical fiber temperature and optical fiber sensing technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of low sensitivity, high cost, and high cost of photonic crystal fibers, and achieve high temperature detection sensitivity and low cost. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

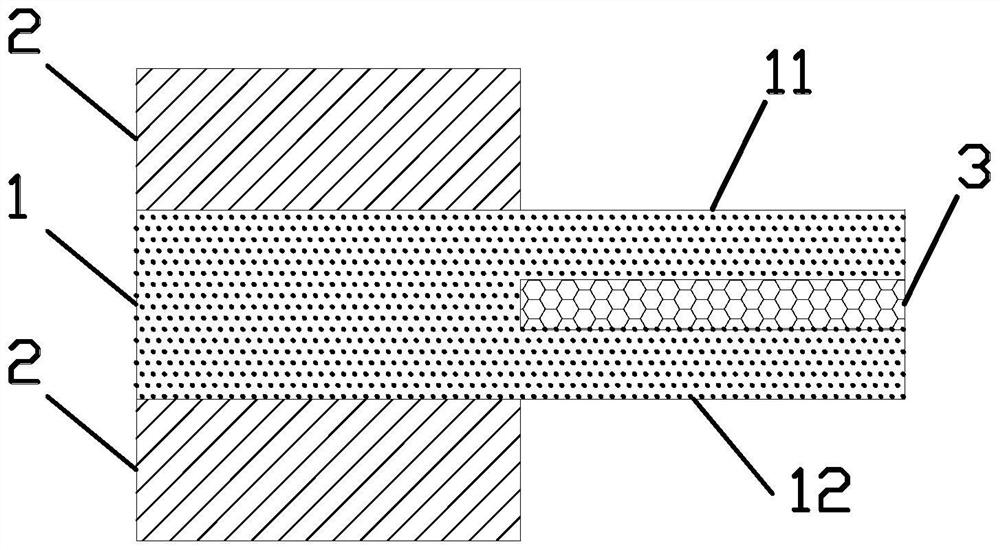

[0026] The invention provides an optical fiber temperature sensor, which includes a light source, a light detector, a circulator, and an optical fiber sensing component. Such as figure 1 As shown, the optical fiber sensing component includes an optical fiber and a thermal expansion material 3 . One end of the optical fiber sensing part is connected to a light source and a light detector through a circulator; at the other end of the optical fiber sensing part, the core 1 protrudes from the cladding 2 . That is to say, at the other end of the optical fiber sensor, the cladding 2 and coating are removed outside the core 1 . In practical applications, only the coating layer can be removed, the key is to reduce the diameter of the optical fiber, making the optical fiber thinner. A slot is provided in the fiber core 1 , and the slot divides the fiber core into a first extension part 11 and a second extension part 12 . The first extension part 11 and the second extension part 12 a...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 As shown, the lengths of the first extension 11 and the second extension 12 are equal. The lengths of the first extension 11 and the second extension 12 are greater than 1 micron and less than 10 microns, so as to form a resonant cavity in the first extension 11 and the second extension 12 . exist figure 1 On the right side of , when light passes from the core 1 into the first extension 11 and the second extension 12 . Reflection is formed on the right end surfaces of the first extension 11 and the second extension 12 , and resonance is formed in the first extension 11 and the second extension 12 . The width of the slit and the change of the refractive index of PDMS in the slit change the resonant wavelength in the first elongated part 11 and the second elongated part 12 . Temperature detection is realized through the change of the resonant wavelength in the first extension 11 and the second extension 12 . In this embodime...

Embodiment 3

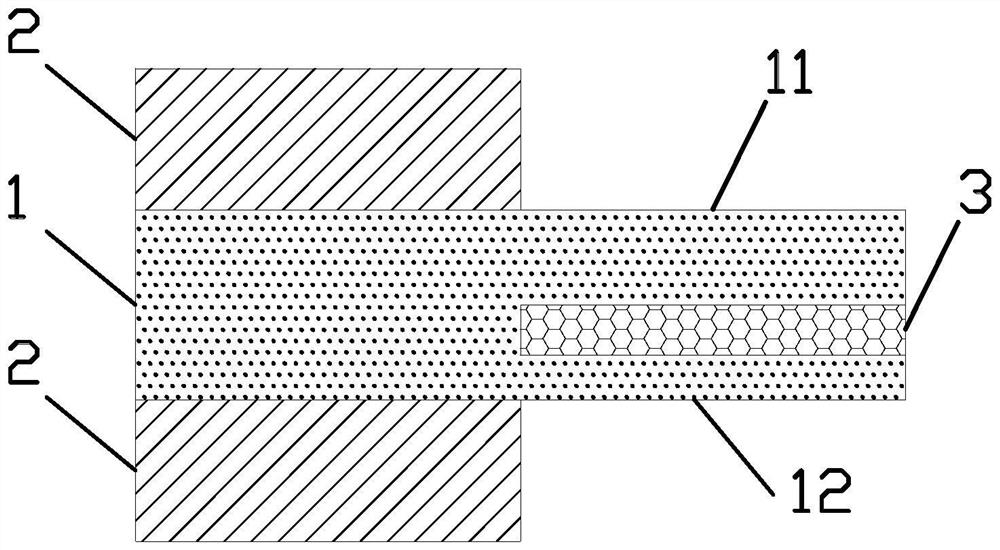

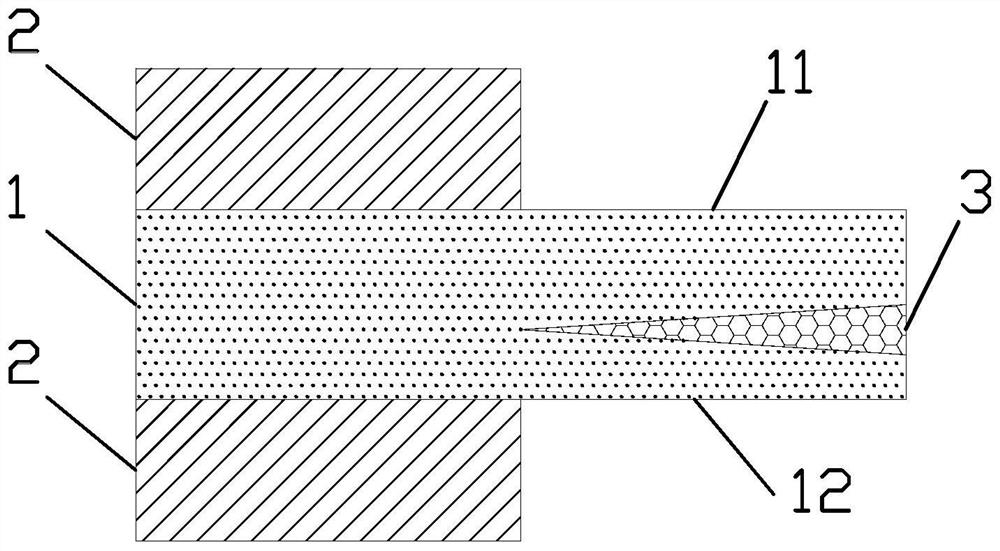

[0033] On the basis of Example 2, such as figure 2 As shown, the thickness of the first extension portion 11 is greater than the thickness of the second extension portion 12 . That is, the first extension 11 is thick, and the second extension 12 is thin. In this way, the resonance wavelength in the first extension 11 is different from the resonance wavelength in the second extension 12 . In the reflection spectrum, there are two reflection resonance wavelengths, and the temperature of the environment to be measured can be determined through the shift of the two resonance wavelengths. Compared with embodiment 2, embodiment 3 has two resonant cavities with different shapes or sizes, which can realize the resonance of two situations, and determine the temperature of the environment to be measured through the resonance of the two situations, which has the advantage of high accuracy of results . In addition, since the thickness of the first extension part 11 and the second exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com