A method of preparing a ceramic joint with temperature detection function using rare earth doped oxide glass

A technology of oxide glass and rare earth doping, applied in the field of ceramic joints, can solve the problems of large residual stress and difficult temperature monitoring of ceramic joints, so as to ensure technical stability, realize reliable connection, enhance service monitorability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

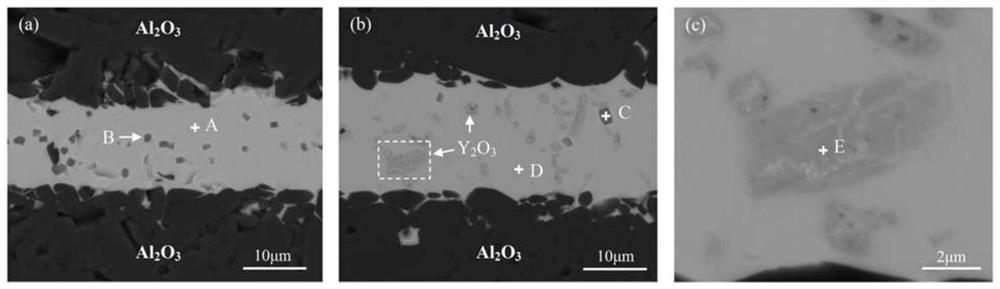

[0025] Specific Embodiment 1: A method of using rare earth-doped oxide glass to prepare a ceramic joint with temperature detection function in this embodiment is carried out according to the following steps:

[0026] 1. Preparation of Rare Earth Doped Oxide Materials

[0027] 1) Weigh the rare earth chloride and matrix material chloride according to the stoichiometric ratio, dissolve in water and stir at room temperature, adjust the pH value of the solution to 10-13 with 2-5mol / L sodium hydroxide to obtain a white turbid solution ;

[0028] 2) Move the above-mentioned white turbid solution to a hydrothermal reaction kettle, wherein the volume filling degree of the reaction kettle is 70%, and then place the reaction kettle in a constant temperature box, and react at a constant temperature of 190-220°C for 7-10 hours; after the reaction is completed, , take out the sample in the reaction kettle, centrifuge at a speed of 8000-12000r / min, wash the precipitate three times with dei...

specific Embodiment approach 2

[0036] Embodiment 2: This embodiment is different from Embodiment 1 in that: the ceramic substrate is an oxide ceramic. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the oxide ceramic is Al 2 o 3 or ZrO 2 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com