Method for continuously precipitating plutonium oxalate

A technology of plutonium oxalate and oxalic acid, which is applied in the field of continuous precipitation of plutonium oxalate, which can solve the problems of reactor wall sticking, low plutonium oxalate production, and small particle size, so as to increase production, reduce sticking and agglomeration , the effect of increasing the amount of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

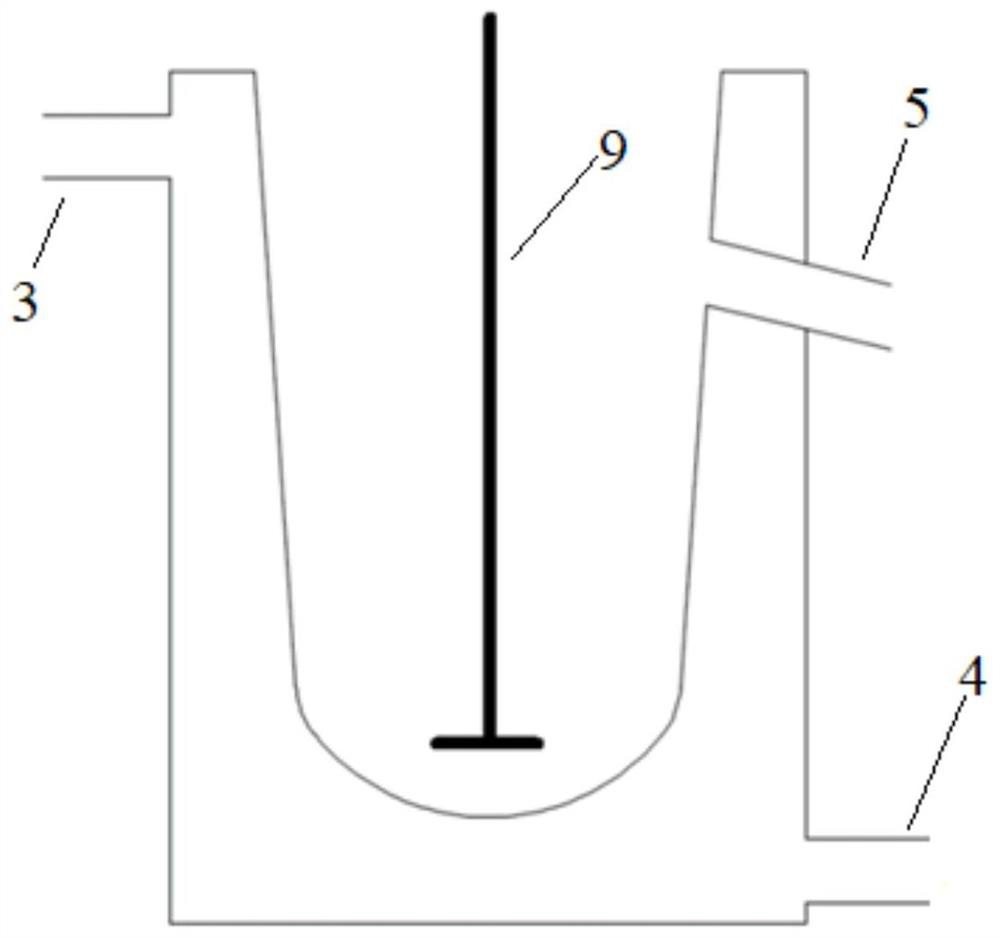

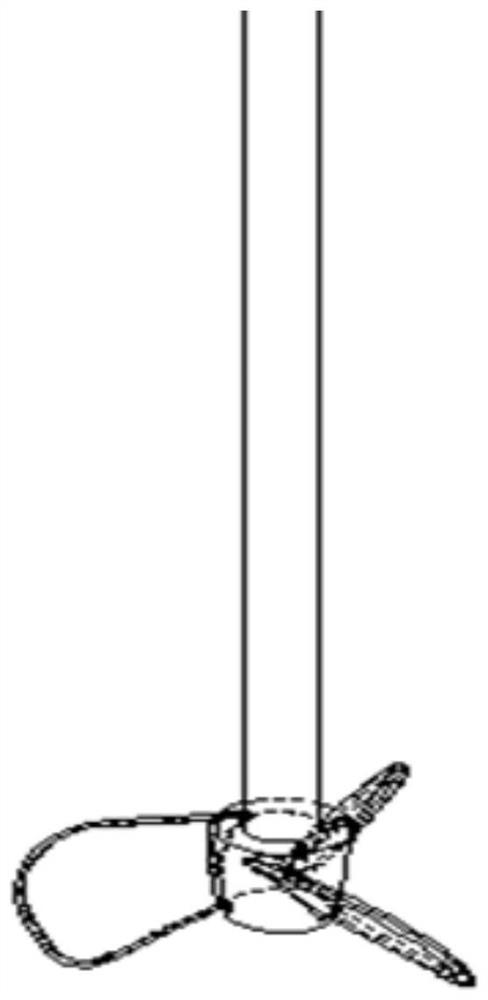

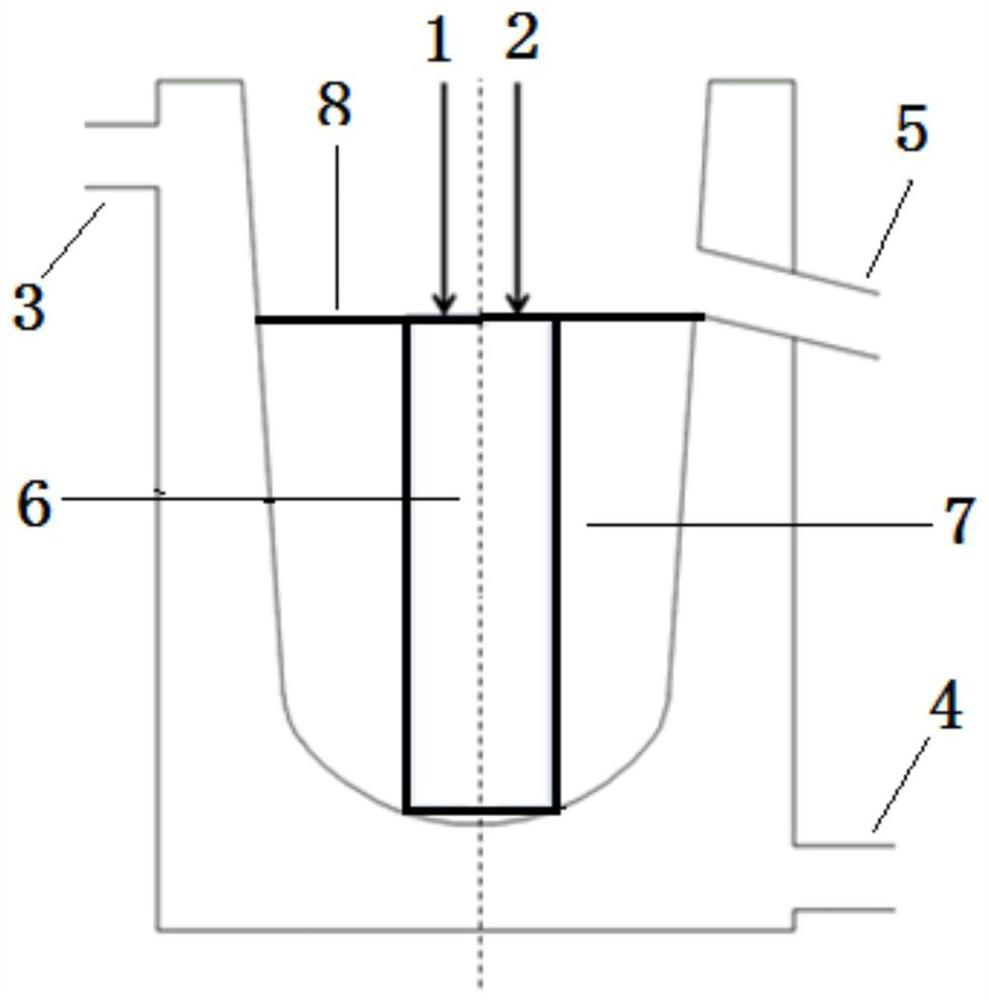

[0058] Add 500.0 mL of combined reagents (2.60 mol / L nitric acid and 0.10 mol / L oxalic acid) preheated to 50 ° C into a 650.0 mL plutonium oxalate precipitation reactor and stir at 550 r / min to make the combined reagents form a flow field; then Heat plutonium(IV) nitrate feed solution (2.4mol / L nitric acid and 25.0g / L Pu(IV) solution) and oxalic acid feed solution (2.2mol / L nitric acid and 0.60mol / L oxalic acid solution) to 50 After ℃, it is continuously added to the plutonium oxalate precipitation reactor for continuous precipitation reaction. The reaction conditions of the continuous precipitation reaction are: the stirring blade is a three-blade propeller, the angle between the three-blade propeller type stirring blade and the horizontal plane is 45 degrees, the stirring paddle is 1.0 cm away from the bottom of the plutonium oxalate precipitation reactor, and the diameter of the stirring paddle is 3.5cm, the stirring rate is 550r / min; adjust plutonium (IV) nitrate feed liqu...

Embodiment 2

[0060] The method for the continuous precipitation of plutonium oxalate is the same as in Example 1, the difference being that the plutonium (IV) nitrate and oxalic acid feed solutions are fed to the central vortex area, and the oxalic acid feed solution is added to the peripheral vortex area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com