Symmetrical battery and preparation method thereof

A symmetrical battery and electrode technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing. It can solve the problems of high environmental requirements for disassembly, the need for secondary packaging, and complicated processes. Improve efficiency and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

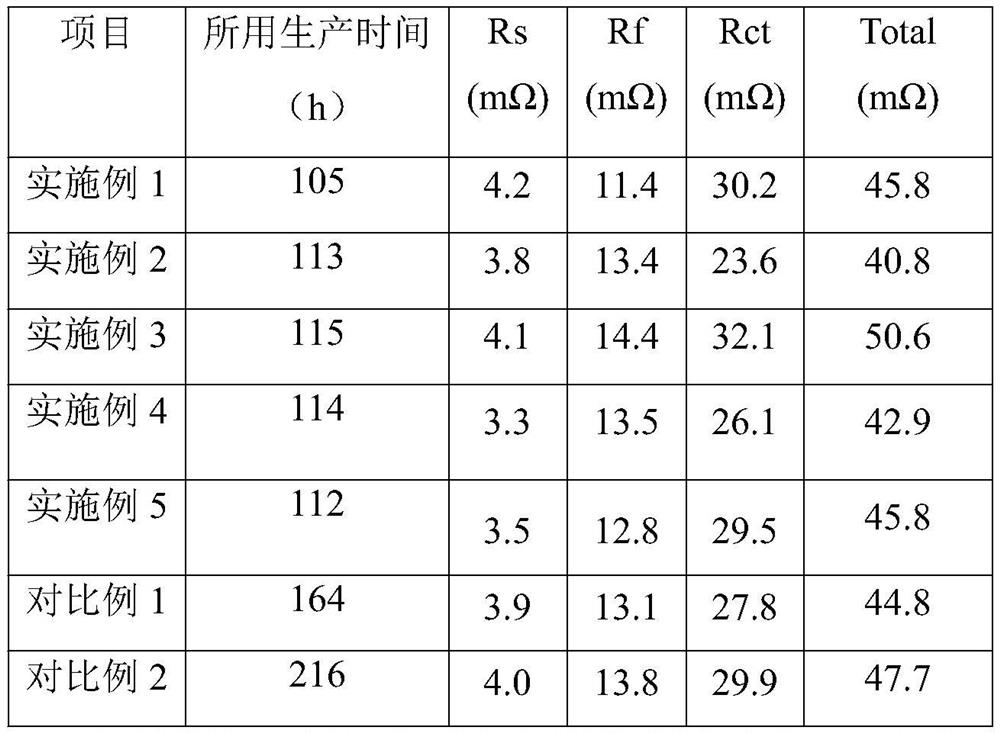

Examples

Embodiment 1

[0028] A method for preparing a symmetrical battery, comprising the following steps:

[0029] Step S1, select two working electrodes of equal size, which are denoted as the first working electrode and the second working electrode;

[0030] Step S2, selecting a metal lithium sheet, and rolling the metal lithium sheet onto the surface of the first working electrode to obtain an adjusting electrode;

[0031] Step S3, selecting the isolation film, welding the first tab to the adjusting electrode, welding the second tab to the second working electrode, stacking the adjusting electrode, the isolation film, and the second working electrode in order to form a cell;

[0032] Step S4, select the electrolyte and the case, put the battery cell into the case, make the first tab and the second tab protrude from the case, inject the electrolyte into the case, seal and package the case, let it stand, charge and discharge , Degassing package made symmetrical battery.

[0033] Wherein, the re...

Embodiment 2

[0039] The difference from Example 1 is that: the standing temperature in step S4 is 58°C, and the standing time is 65h.

[0040] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] The difference from Example 1 is that: the standing temperature in step S4 is 50°C, and the standing time is 75h.

[0043] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com