Thermal floating type inverter

An inverter, floating technology, applied in the field of thermal floating inverter, can solve the problem of increasing the gap of the heat dissipation hole, and achieve the effect of increasing the gap, improving the heat dissipation efficiency, and reducing the aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

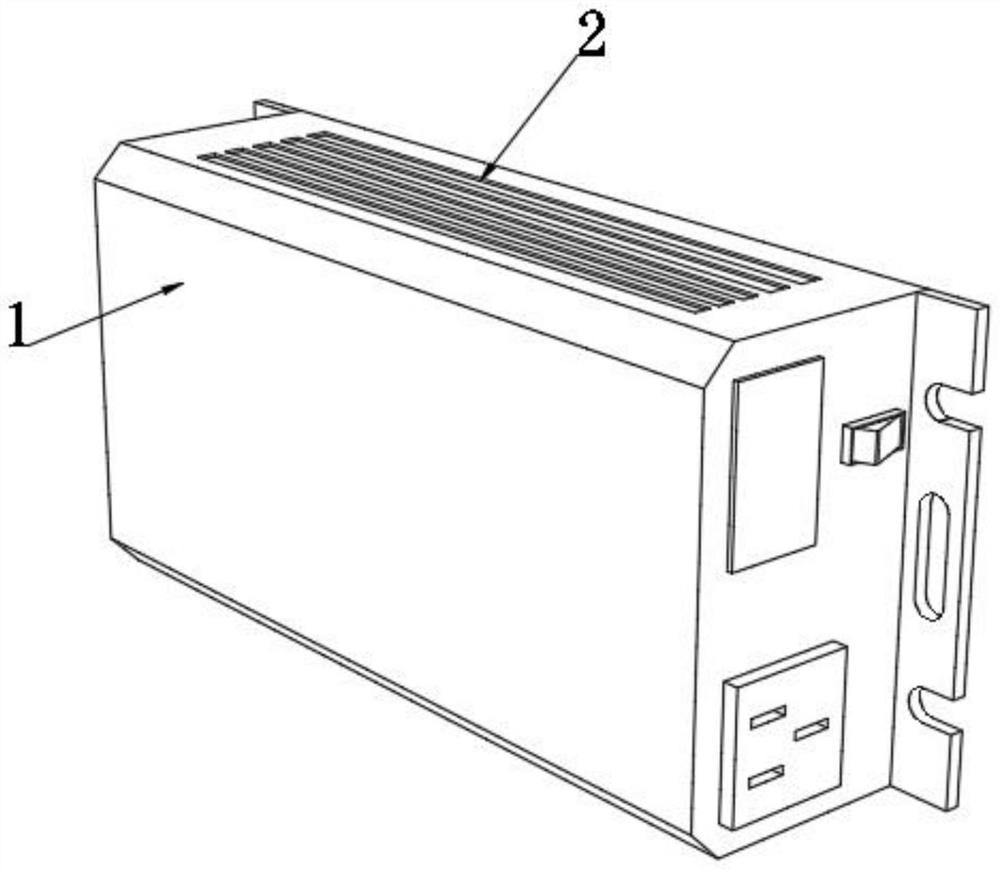

[0037] see figure 1 , a thermal floating inverter, including an inverter body 1, a plurality of evenly distributed heat dissipation holes 2 are arranged on the outer shell of the inverter body 1, and inner stays 3 are fixedly connected to the inner walls of the heat dissipation holes 2, where It should be noted that when in use, the inner stays 3 are only installed in the cooling holes 2 on the upper side.

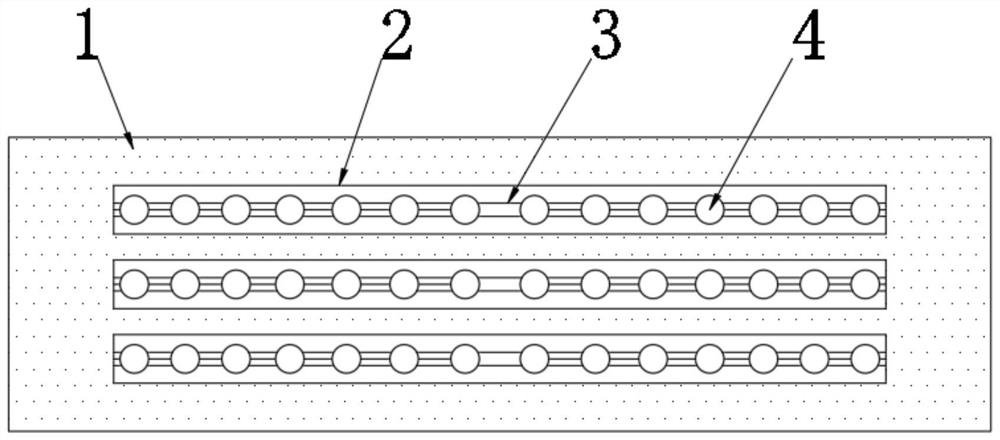

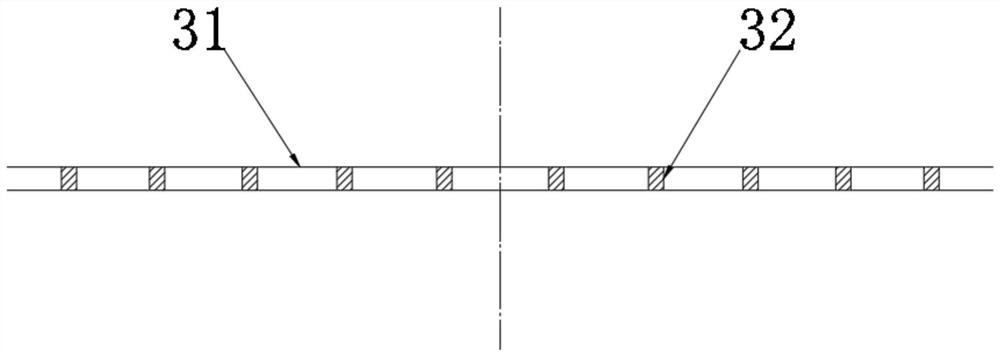

[0038] see Figure 2-4 , the inner stay 3 includes two side wires 31 on the same horizontal plane and a plurality of positioning pieces 32 connected between the two side wires 31, and the inner wall of the cooling hole 2 is also fixedly connected with two mutually symmetrical floating bars 4, as Figure 5 The floating bar 4 includes a plurality of heat-reflecting balls 41 and a series bar 42 connected between two adjacent heat-reflecting balls 41, and the heat-reflecting balls 41 near the left and right inner walls of the heat dissipation hole 2 are also connected with th...

Embodiment 2

[0044] see Figure 9-10 , the position corresponding to the series bar 42 in the active floating end 411 is fixedly connected with the air shield 71, and the limit rope 72 is fixedly connected between the end of the air shield 71 and the inner wall of the active floating end 411. Since the active floating end 411 expands and deforms when heated, The limit rope 72 can effectively limit the position of the air shield 71, making it difficult to change its orientation with its deformation, thereby effectively ensuring that the thermal reflection ball 41 can move smoothly along the series bar 42. One end of the series bar 42 moves through the active floating end 411 and Extending into the air shield 71, the other end of the series bar 42 is fixedly connected to another active floating end 411 adjacent to it, and the series bar 42 is a T-shaped hard structure, and the air shield 71 is a hard sealing structure, which is convenient for the floating bar 4 After the lifting angle is inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com