Phase equilibrium determination and separation device and application method thereof

A separation device and phase balance technology, applied in the field of chemical engineering, can solve the problems of high cost, low applicable temperature, long time required for phase balance, etc., and achieve the effect of good effect and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

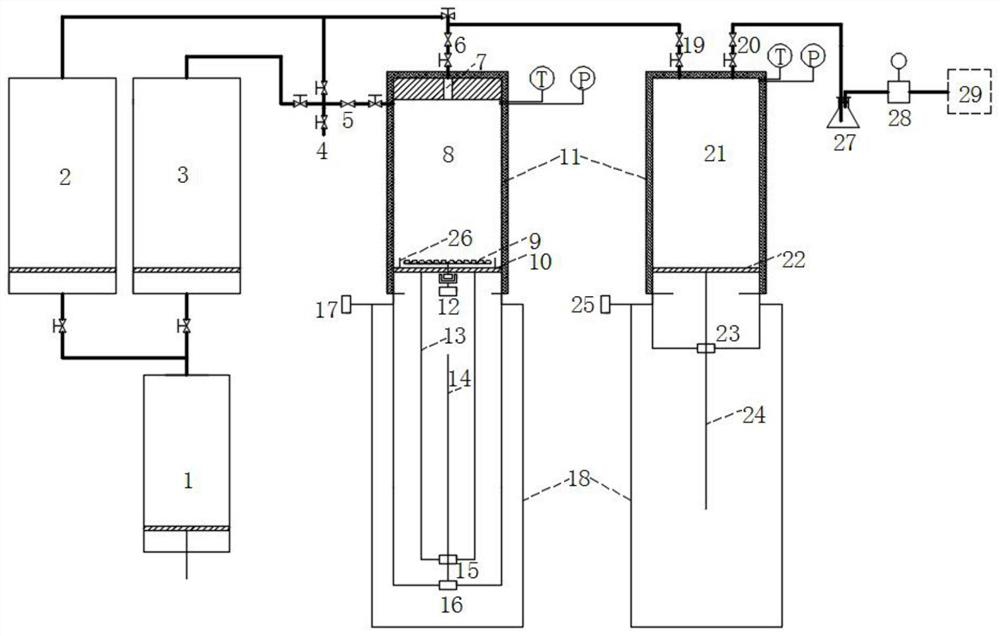

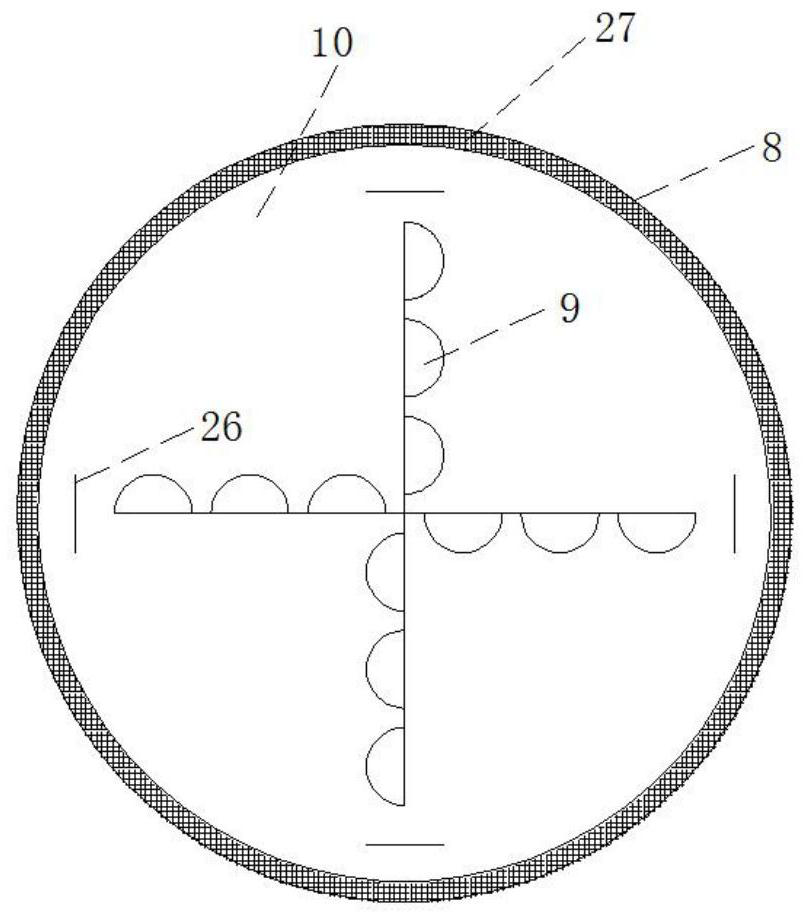

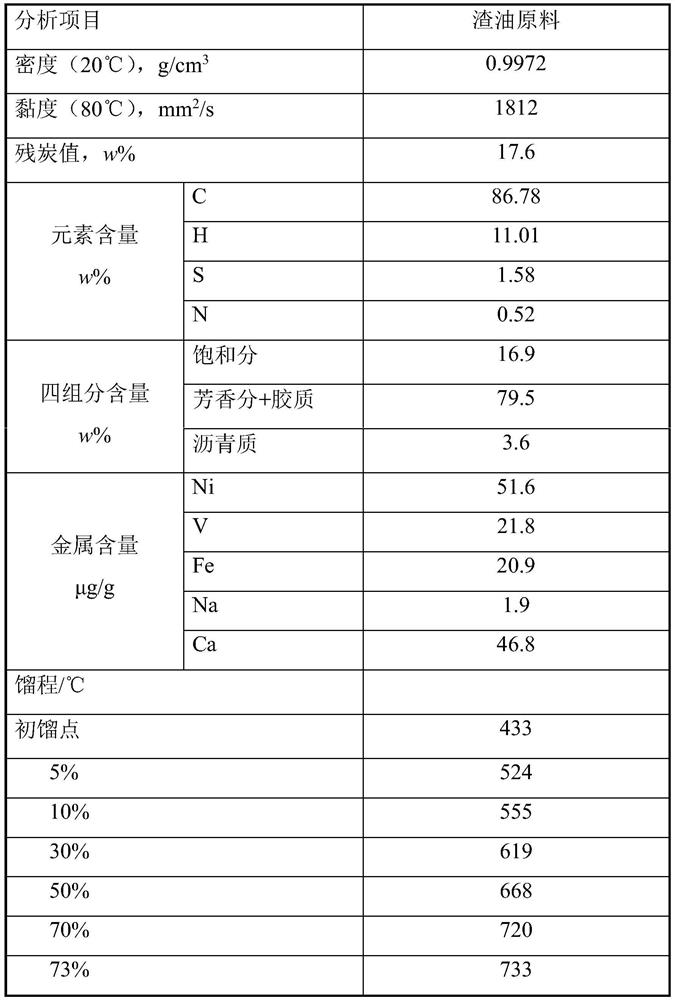

[0081] Use as attached figure 1 In the phase balance measurement and separation device shown, the balance space in the balance main kettle has an inner diameter of 80mm and a height of 100mm, and the window is a sapphire cylinder with an inner diameter of 10mm and a height of 30mm. The inner diameter of the balance auxiliary kettle is 100mm, and the height is 100mm. The residual oil used was obtained from Wuhan Branch of China Petroleum & Chemical Corporation, and its properties are shown in Table 1.

[0082] Utilize negative pressure to inhale the residual oil 120g after heating in the balance main kettle 8; Utilize the high-precision plunger pump 1 to press the n-butane solvent in the solvent tank 3 into the balance main kettle 8, record the n-butane solvent feed temperature, Pressure and volume: Heat the balanced main kettle 8 to the reaction temperature of 120°C and keep it warm, start stirring, set the 8 pistons of the balanced main kettle to the pressure holding mode of...

Embodiment 2

[0085] The phase balance measurement and separation device, residual oil raw material, and implementation steps used are the same as those in Example 1, except that the stirring time is 4 hours.

Embodiment 3

[0087] The phase balance measurement and separation device, residual oil raw material, and implementation steps adopted are the same as those in Example 1. The difference is that the test solvent is n-pentane, the test temperature is 220° C., and the test pressure is 16 MPa. The obtained phase balance data are listed in the table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com