Novel bamboo-steel-building waste combined component and manufacturing method

A technology of construction waste and manufacturing method, which is applied in the direction of pillars, pier columns, columns, etc., can solve the problems of poor stability and fire resistance, environmental impact of building materials, and low bearing capacity of bamboo and wood components, so as to improve fire resistance and shorten The effect of improving the construction period and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

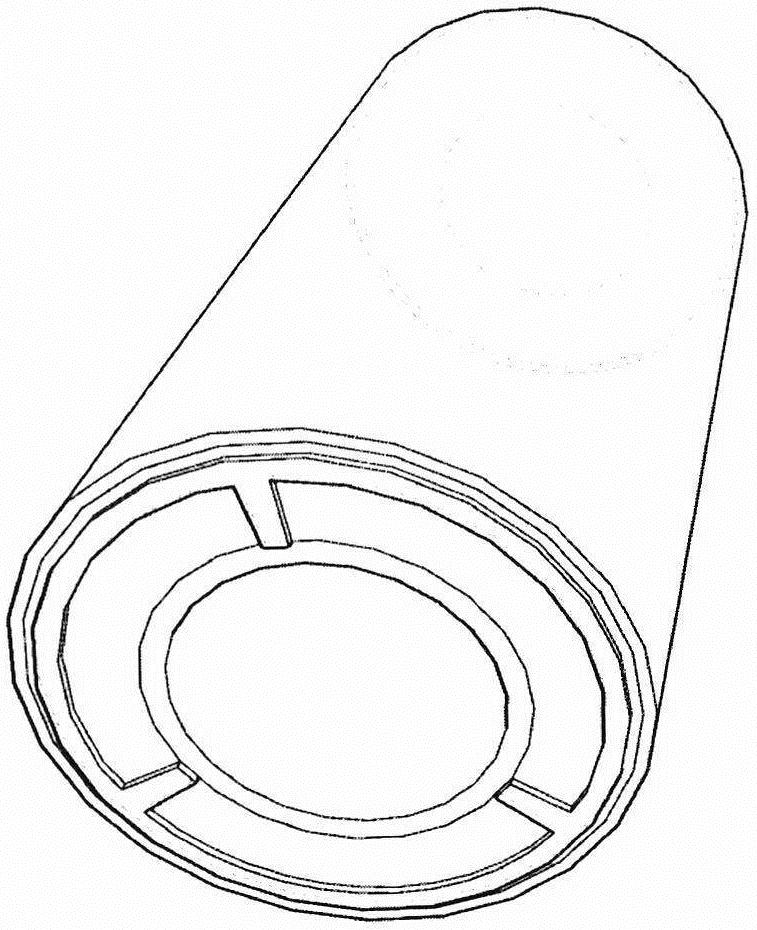

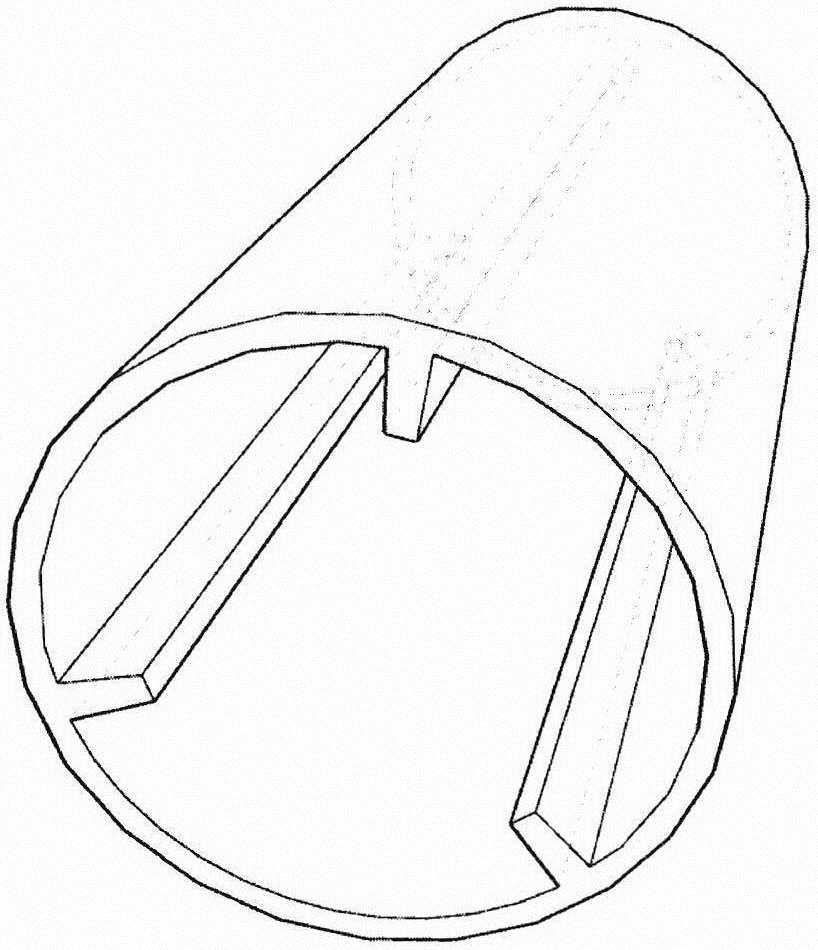

[0014] The overall structure of the combined column produced by the present invention such as Figure 1 As shown, hollow ribbed thin-walled steel cylinders as shown Figure 2 as shown.

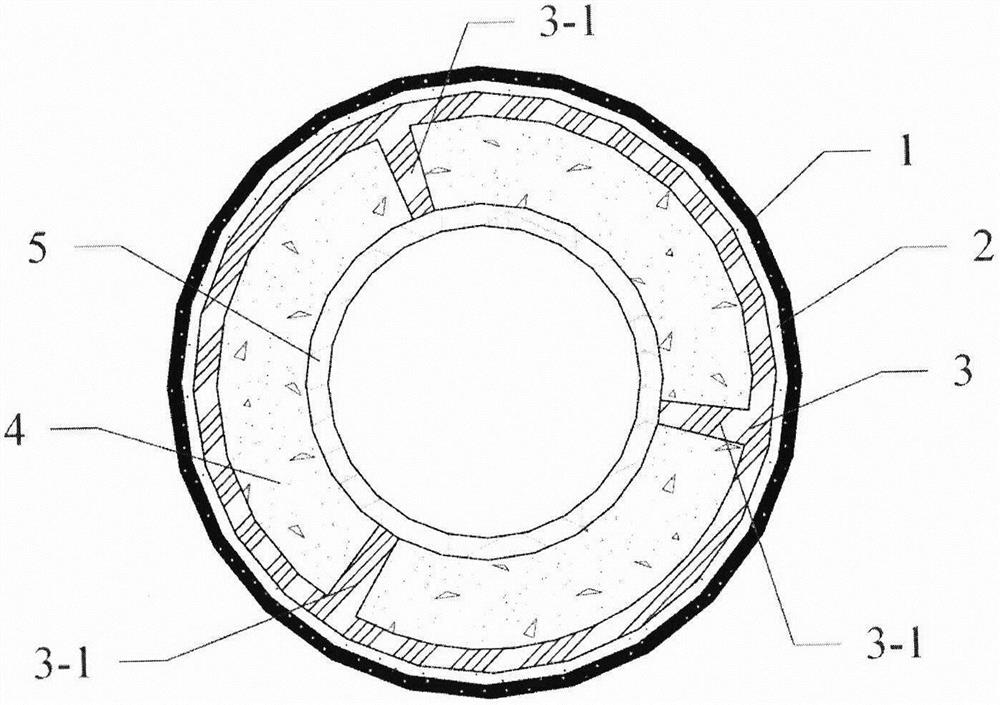

[0015] A new bamboo-steel-construction waste combination component and manufacturing method, the components from the outside to the inside are FRP layer (1), cork layer (2), hollow ribbed thin-walled steel cylinder (3), construction waste (4) and bamboo cylinder (5); control Figure 2 , hollow ribbed thin-walled steel cylinder (3) is cast by the factory at one time; Figure 3 Three steel ribs (3-1) the hollow ribbed thin-walled steel cylinder (3) the circular section is tri-aliquoted and along the hollow ribbed thin-walled steel cylinder (3) the axial inward distribution, the thickness of the steel rib (3-1) is not less than 5mm; the bamboo cylinder (5) is placed into the hollow ribbed thin-walled steel cylinder (3) inside, the bamboo cylinder (5) is fixed through the three steel ribs (3-1) in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com