Automatic fish tofu processing equipment and processing method thereof

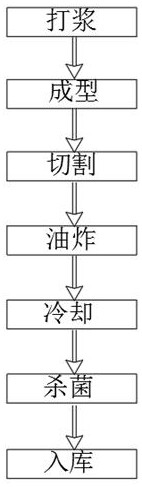

A processing method and technology of processing equipment, applied in fish processing, slaughtering, food science and other directions, can solve the problems of low work efficiency and high production cost, and achieve the effects of improving mixing quality, saving raw materials, and improving beating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

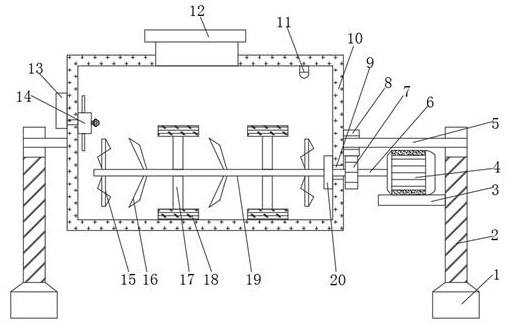

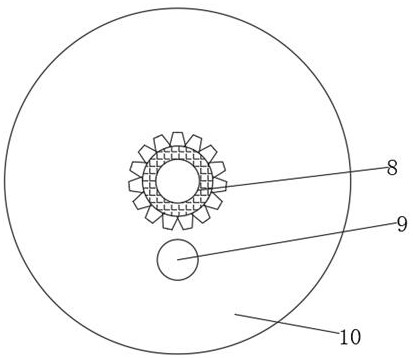

[0036] refer to Figure 1-3 , a fish tofu automatic processing equipment, including a box 10 and a base 1, one side of the box 10 is welded with a feed pipe 12, the upper surface of the base 1 is welded with a fixed column 2, and one side of the fixed column 2 is fixed by a bolt There is a mounting plate 3, the upper surface of the mounting plate 3 is fixed with a motor 4 by a bolt, one end of the output shaft of the motor 4 is fixed with a transmission rod 6 by a bolt, and the other end of the transmission rod 6 is fixed with a central rod 19 by a bolt, and the central rod 19 Located inside the box body 10, one side of the transmission rod 6 is keyed to the first gear 7, and one side of the box body 10 is fixed with a hollow gear 8 by bolts, and the hollow gear 8 is located at the center of one side of the box body 10, fixed One side of the column 2 is rotatably connected with a rotating rod 5, and the other end of the rotating rod 5 passes through the hollow gear 8 and is fi...

Embodiment 2

[0049] refer to Figure 1-3 , a fish tofu automatic processing equipment, including a box 10 and a base 1, one side of the box 10 is welded with a feed pipe 12, the upper surface of the base 1 is welded with a fixed column 2, and one side of the fixed column 2 is fixed by a bolt There is a mounting plate 3, the upper surface of the mounting plate 3 is fixed with a motor 4 by a bolt, one end of the output shaft of the motor 4 is fixed with a transmission rod 6 by a bolt, and the other end of the transmission rod 6 is fixed with a central rod 19 by a bolt, and the central rod 19 Located inside the box body 10, one side of the transmission rod 6 is keyed to the first gear 7, and one side of the box body 10 is fixed with a hollow gear 8 by bolts, and the hollow gear 8 is located at the center of one side of the box body 10, fixed One side of the column 2 is rotatably connected with a rotating rod 5, and the other end of the rotating rod 5 passes through the hollow gear 8 and is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com