Makeup fixing spray with oil control effect and preparation method thereof

A film-forming agent and emulsifier technology, which is applied in the field of makeup setting spray and its preparation, can solve the problems of skin irritation, image impact, and low content of film-forming components, and achieve the effect of reducing oil secretion and affecting makeup and maintaining makeup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

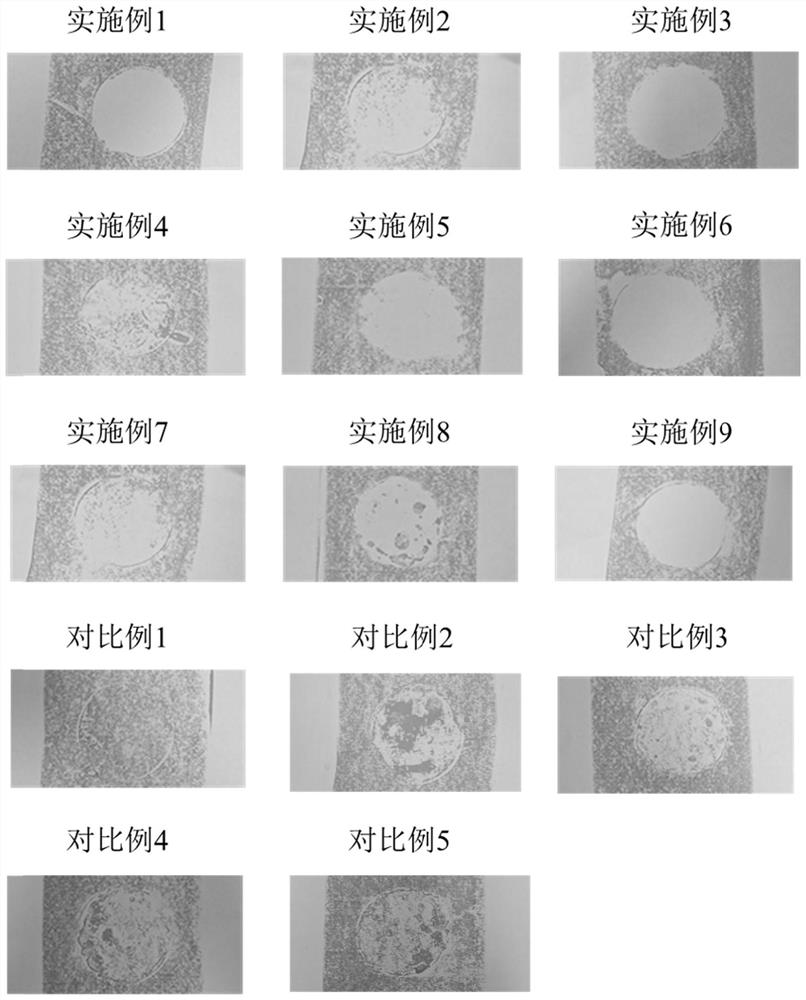

Examples

Embodiment 1

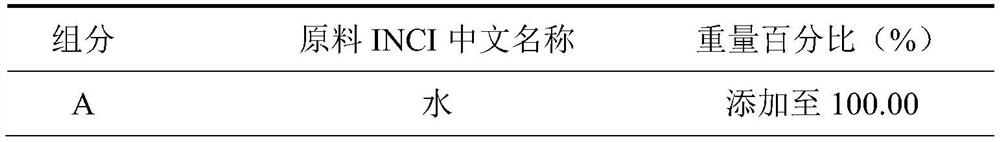

[0051] This embodiment provides a makeup setting spray with an oil control effect, and the specific ingredients are shown in Table 1.

[0052] The formula of the makeup setting spray of table 1 embodiment 1

[0053]

[0054]

[0055] The production method is as follows:

[0056] (1) Heat and stir the raw materials of phase B and C separately in advance, and set the temperature at 80°C; dissolve the raw materials of phase D until transparent;

[0057] (2) Put the raw materials of phases A to D into the water phase pot, set the temperature to 80°C, and mix for 5 minutes at a stirring speed of 300rpm / min while keeping warm;

[0058] (3) Put the phase E raw materials into the emulsification pot, raise the temperature to 75°C, and mix for 3 minutes at a stirring speed of 800rpm / min;

[0059] (4) Pump the water phase into the emulsification pot at a constant speed under stirring, emulsify for 1 minute, and emulsify for 4 minutes at a homogeneous speed of 3000 rpm / min after t...

Embodiment 2

[0063] This embodiment provides a makeup setting spray with an oil control effect, and the specific ingredients are shown in Table 2.

[0064] The formula of the makeup setting spray of table 2 embodiment 2

[0065]

[0066] The production method is as follows:

[0067] (1) Heat and stir the raw materials of phase B and C separately in advance, and set the temperature to 70°C; dissolve the raw materials of phase D until transparent;

[0068] (2) Put the raw materials of phases A to D into the water phase pot, set the temperature to 85°C, and mix for 5 minutes at a stirring speed of 1000rpm / min under the state of heat preservation;

[0069] (3) Put the phase E raw materials into the emulsification pot, raise the temperature to 85°C, and mix for 3 minutes at a stirring speed of 1000rpm / min;

[0070] (4) Pump the water phase into the emulsification pot at a constant speed under stirring, emulsify for 2 minutes, and emulsify for 5 minutes at a homogeneous speed of 3000 rpm / mi...

Embodiment 3

[0074] This embodiment provides a makeup setting spray with an oil control effect, and the specific ingredients are shown in Table 3.

[0075] The formula of the makeup setting spray of table 3 embodiment 3

[0076]

[0077] The production method is as follows:

[0078] (1) Heat and stir the raw materials of phase B and C separately in advance, and set the temperature to 70°C; dissolve the raw materials of phase D until transparent;

[0079] (2) Put the raw materials of phases A to D into the water phase pot, set the temperature to 70°C, and mix for 3 minutes at a stirring speed of 300rpm / min under the state of heat preservation;

[0080] (3) Put the phase E raw materials into the emulsification pot, raise the temperature to 70°C, and mix for 3 minutes at a stirring speed of 200rpm / min;

[0081] (4) Pump the water phase into the emulsification pot at a constant speed under stirring, emulsify for 1 minute, and emulsify for 4 minutes at a homogeneous speed of 500 rpm / min af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com